Optimizing Mixer Settler Design for Enhanced Performance

Selecting the Right Configuration and Materials

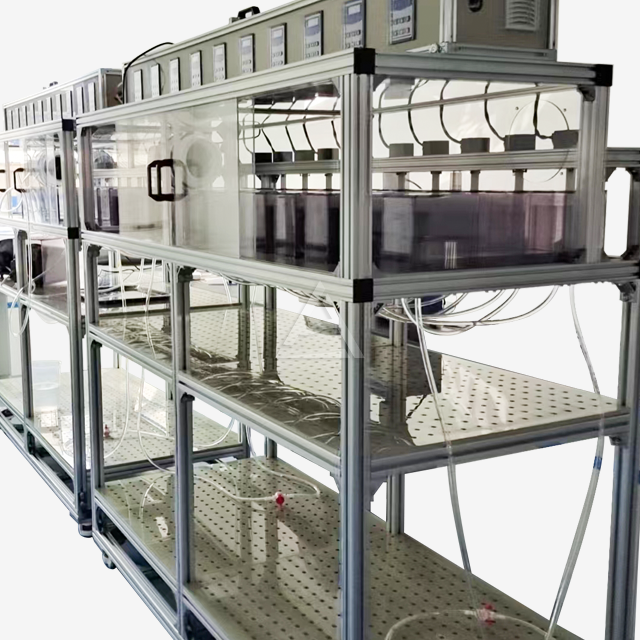

Choosing the appropriate mixer settler configuration is crucial for achieving optimal performance in chemical processes. Engineers should consider factors such as the desired mixing volume, plate thickness, and material compatibility when selecting a mixer settler. For instance, desktop base editions may be suitable for laboratory-scale operations, while mobile standard editions offer flexibility for pilot plant applications. Environmentally friendly high editions are ideal for large-scale industrial processes that require stringent environmental compliance.

Material selection plays a vital role in ensuring the longevity and efficiency of mixer settlers. Common materials include PP, PPH, PVC, PMMA, PTFE, PEEK, stainless steel, and titanium. Each material offers unique properties that cater to specific chemical environments and process requirements. For example, PTFE and PEEK are excellent choices for corrosive applications, while stainless steel and titanium provide superior mechanical strength and durability.

Incorporating Advanced Features for Process Control

Modern mixer settlers can be equipped with various optional features to enhance process control and efficiency. Temperature control devices allow precise regulation of reaction conditions, while pH adjustment mechanisms ensure optimal chemical equilibrium. Water-bath jacket devices provide excellent temperature uniformity, and anti-overflow tank systems prevent spillage and improve safety. Watch window devices enable visual monitoring of the extraction process, facilitating real-time adjustments and troubleshooting.

Customizing Mixer Settler Dimensions and Capacity

Tailoring mixer settler dimensions to specific process requirements is essential for maximizing efficiency. Engineers can choose from standard mixing volumes ranging from 200ml to 3L or opt for customized sizes to meet unique application needs. Additionally, adjustable mixer-settler stage amounts allow for fine-tuning of the extraction process, while variable agitator speeds and phase interface height controls offer further optimization possibilities.

Implementing Effective Operational Strategies for Mixer Settlers

Optimizing Mixing and Settling Parameters

Achieving the right balance between mixing intensity and settling time is crucial for efficient liquid-liquid extraction. Engineers should carefully adjust agitator speeds to ensure thorough mixing without creating excessive emulsification, which can hinder phase separation. Settling time must be optimized to allow complete phase disengagement while maintaining process throughput. Advanced monitoring techniques, such as real-time phase interface detection, can help fine-tune these parameters for optimal performance.

Managing Flow Rates and Phase Ratios

Proper control of flow rates and phase ratios is essential for achieving high extraction rates and perfect separation effects. Engineers should consider factors such as the physical properties of the liquids, desired extraction efficiency, and equipment limitations when setting flow rates. Maintaining the correct organic-to-aqueous phase ratio is crucial for maximizing mass transfer and minimizing solvent consumption. Implementing adaptive flow control systems can help maintain optimal conditions even as process variables fluctuate.

Leveraging Process Automation and Data Analytics

Integrating process automation and data analytics into mixer settler operations can significantly enhance performance and reliability. Advanced control systems can continuously monitor and adjust key parameters such as temperature, pH, and flow rates to maintain optimal extraction conditions. Machine learning algorithms can analyze historical data to identify trends and predict maintenance needs, reducing downtime and improving overall process efficiency. Implementing digital twin technology allows for real-time simulation and optimization of mixer settler performance across various operating scenarios.

Maintaining and Troubleshooting Mixer Settlers for Long-term Efficiency

Developing Comprehensive Maintenance Protocols

Regular maintenance is essential for ensuring the longevity and consistent performance of mixer settlers. Engineers should develop and implement comprehensive maintenance schedules that include routine inspections, cleaning procedures, and component replacements. Special attention should be paid to critical components such as agitators, seals, and valves, which are prone to wear and fouling. Implementing preventive maintenance strategies, such as vibration analysis and thermal imaging, can help identify potential issues before they lead to equipment failure.

Addressing Common Operational Challenges

Even with proper design and maintenance, mixer settlers may encounter operational challenges that require troubleshooting. Common issues include emulsion formation, phase inversion, and insufficient separation. Engineers should be prepared to diagnose and address these problems promptly. Techniques such as adjusting interface height, modifying agitation parameters, or introducing coalescence-enhancing additives can help resolve separation issues. In cases of persistent problems, consulting with equipment manufacturers or process specialists may be necessary to develop tailored solutions.

Continuous Improvement and Process Optimization

To maintain peak performance over time, engineers should adopt a continuous improvement approach to mixer settler operations. This involves regularly reviewing process data, conducting performance audits, and staying updated on technological advancements in liquid-liquid extraction. Implementing pilot-scale testing for new applications or process modifications can help optimize operating parameters before full-scale implementation. Engaging in knowledge-sharing initiatives with industry peers and participating in relevant conferences can provide valuable insights for enhancing mixer settler efficiency and expanding their application range.

Conclusion

Implementing best practices for using mixer settlers in chemical process engineering is crucial for achieving optimal performance, efficiency, and reliability. By focusing on proper design selection, operational strategy implementation, and proactive maintenance, engineers can maximize the benefits of these versatile extraction devices. As industries continue to demand more efficient and sustainable separation processes, the role of well-optimized mixer settlers in chemical engineering operations will only grow in importance.

Contact Us

Elevate your chemical process engineering operations with Cuiyan Technology's advanced mixer settler solutions. Our cutting-edge designs offer high extraction rates, perfect separation effects, and unparalleled customization options. Experience the benefits of improved efficiency, reduced operational costs, and enhanced process control. Contact us today at wangzhijun@cuiyan-tec.com to discover how our expertise can transform your liquid-liquid extraction processes.