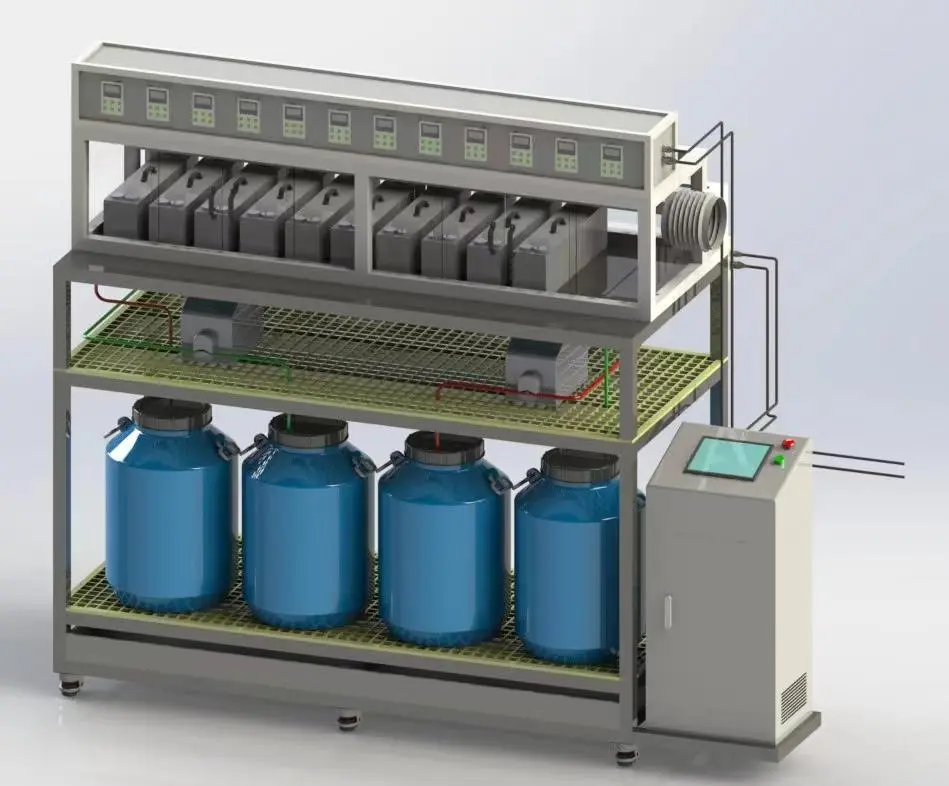

Liquid Extraction Equipment

Configuration:desktop base edition, mobile standard edition, environmentally friendly high edition

Mixing volumn: 200ml, 300ml, 500ml, 1L, 2L, 3L or customized

Plate thickness:5mm,6mm,8mm,10mm

Material: PP,PPH,PVC,transparent PVC,PMMA,PTFE,PEEK,SUS,Ti

Production process: welding,bonding,bending,injection molding,integral forming

Optional function: temperature control device, pH adjustment device, water-bath jacket device, anti-overflow tank device,watch window device

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable mixer-settler stage amount, adjustable agitator speed, and adjustable phase interface height;Highly customizable

Application:rare earth extraction;nickel cobalt extraction;rubidium cesium extraction;salt lake brine extraction;nuclear extraction;isotope extraction;lithium battery recycling;vanadium battery recycling;copper electroplate recycling;biological wastewater recycling

- Product Description

Shaanxi Cuiyan: Your Trusted Liquid Extraction Equipment Manufacturer & Supplier

Since 2012, Shaanxi Cuiyan Technology Co., Ltd has specialized in advanced liquid extraction equipment for labs, pilot projects, and industrial applications. With a team of 37 experts and 9 core advantages—including automation integration, modular energy-saving designs, and patented extraction technology—we deliver reliable, customizable solutions trusted by 300+ global clients.

Liquid Extraction Equipment Description

Our lab-scale liquid extraction equipment combines precision engineering with flexible configurations to meet diverse separation needs. Ideal for R&D and small-scale production, it ensures high extraction rates, leak-free operation, and user-friendly controls.

Specifications

| Specifications | Details |

|---|---|

| Configuration | Desktop Base, Mobile Standard, Eco-Friendly High Edition |

| Mixing Volume | 200ml–3L (Customizable) |

| Plate Thickness | 5mm–10mm |

| Material | PP, PPH, PVC, Transparent PVC, PMMA, PTFE, PEEK, SUS, Ti |

| Production Process | Welding, Bonding, Bending, Injection Molding, Integral Forming |

| Optional Functions | Temperature Control, pH Adjustment, Water-Bath Jacket, Anti-Overflow Tank |

Why Choose Us?

- Precision & Efficiency: Achieve 95%+ extraction rates with adjustable agitators and phase interfaces.

- Durability: Corrosion-resistant materials (e.g., PTFE, SUS316L) ensure longevity in harsh environments.

- Customization: Tailor mixing volumes, sensors, or tank designs to your process.

- Modular Flexibility: Rapid installation and scalability for evolving workflows.

- Energy-Saving Design: Reduce operational costs with optimized fluid dynamics.

Material & Processing

We use FDA-compliant polymers (PP, PVC) and metals (Ti, SUS) for chemical resistance and transparency. Advanced techniques like CNC bending and PEEK injection molding guarantee leak-proof, precision-fit components.

Key Functions

- Anti-Bubbling Technology: Stable phase separation for consistent results.

- One-Step Filling/Emptying: Save time with simplified operation.

- Real-Time Monitoring: Integrated sensors for pH, temperature, and liquid levels.

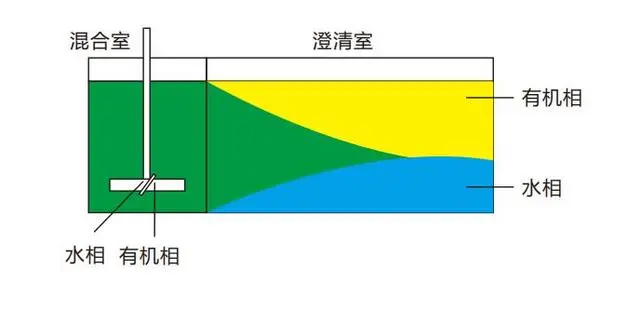

How It Works?

- Mixing: Agitators blend liquids to transfer target compounds.

- Settling: Gravity separates phases in clarified zones.

- Collection: Adjustable weirs control interface levels for pure output.

Applications

- Metals: Rare earth, nickel-cobalt, rubidium-cesium extraction.

- Energy: Lithium/vanadium battery recycling, salt-lake brine processing.

- Environment: Bio-waste treatment, copper electroplating recovery.

Physical Display

We provide a selection of advanced equipment to meet various demands. Join us at our factory for a live demo or explore Liquid Extraction Equipment images to see them in action.

User Guide

- Setup

- During the setup phase, begin by carefully unpacking the modular components of the system. Each module is designed for easy assembly; align the connection points precisely and fasten them securely using the provided tools. Once the modules are assembled, connect the various sensors. These sensors, which monitor parameters like temperature, pressure, and liquid levels, should be linked to the control unit following the color - coded wiring diagrams. Proper setup ensures seamless operation and accurate data collection during the process.

- Calibration

- Calibration is a crucial step to optimize performance. Use the intuitive digital interface to adjust the agitator speed. The range of 0 - 500 RPM allows for a wide variety of mixing intensities. Start by setting a low speed, perhaps 50 RPM, and observe the mixing action. Gradually increase the speed while monitoring the consistency of the mixture. Fine - tune the setting based on the viscosity of the substances being mixed, ensuring that the agitation is sufficient for thorough blending without causing splashing or excessive foaming.

- Operation

- For operation, first load the feedstock into the designated chamber. Ensure that the feedstock is of the correct quality and quantity as per the process requirements. Once loaded, initiate the automated cycle through the control panel. The system will then execute a pre - programmed sequence of operations, which may include mixing, heating or cooling (if applicable), and separation steps. Monitor the progress on the control panel's display, which shows real - time data on parameters like temperature, pressure, and the status of each operation.

- Maintenance

- Maintenance is key to the longevity of the equipment. Regularly clean the system using mild solvents. This helps to remove any residue from previous processes that could affect subsequent operations. Additionally, inspect the O - rings monthly. O - rings are critical for maintaining seals and preventing leaks. Look for signs of wear, such as cracks or deformities. If any issues are detected, replace the O - rings immediately with compatible spares to ensure the continued efficient and leak - free operation of the system.

Packaging & Transportation

Shock-proof crating with global logistics support.

After-Sales

2-year warranty, lifetime troubleshooting.

Certifications

ISO9001, CE, and 12+ national patents.

FAQ

Q: Can I integrate IoT for remote monitoring?

A: Yes! We offer IoT-ready models with data-logging capabilities.

Q: Are your materials FDA-compliant?

A: Select polymers (PP, PTFE) meet FDA standards for pharmaceutical use.

Q: What's the lead time for custom designs?

A: Typically 4–6 weeks, depending on complexity.

Q: Do you provide installation support?

A: Free video guides + 24/7 technical assistance via email/chat.

Q: How energy-efficient is your equipment?

A: Variable-speed drives cut power use by 30% vs. conventional models.

Contact Us

Need a liquid extraction equipment partner with proven expertise? Email wangzhijun@cuiyan-tec.com for quotes, catalogs, or technical consultations.