Used Extraction Equipment

Configuration:desktop base edition, mobile standard edition, environmentally friendly high edition

Mixing volumn: 200ml, 300ml, 500ml, 1L, 2L, 3L or customized

Plate thickness:5mm,6mm,8mm,10mm

Material: PP,PPH,PVC,transparent PVC,PMMA,PTFE,PEEK,SUS,Ti

Production process: welding,bonding,bending,injection molding,integral forming

Optional function: temperature control device, pH adjustment device, water-bath jacket device, anti-overflow tank device,watch window device

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable mixer-settler stage amount, adjustable agitator speed, and adjustable phase interface height;Highly customizable

Application:rare earth extraction;nickel cobalt extraction;rubidium cesium extraction;salt lake brine extraction;nuclear extraction;isotope extraction;lithium battery recycling;vanadium battery recycling;copper electroplate recycling;biological wastewater recycling

- Product Description

Shaanxi Cuiyan: Your Trusted Used Extraction Equipment Manufacturer & Supplier

Shaanxi Cuiyan Technology Co., Ltd, established in 2012, specializes in used extraction equipment designed for lab, pilot, and industrial applications. With over 300 global clients and 10,000+ stages sold, our refurbished systems combine cost-effectiveness with advanced engineering. Our equipment supports automation, modular scalability, and customization—ideal for industries prioritizing budget-friendly, reliable solutions.Optimize your extraction processes with our used product, rebuilt to meet modern standards. Perfect for small-scale trials or pilot projects, this system ensures high extraction rates, leak-free operation, and adaptable configurations.

Used Extraction Equipment Specifications

| Specifications | Details |

|---|---|

| Configurations | Desktop Base, Mobile Standard, Eco-Friendly High Edition |

| Mixing Volume | 200ml–3L (Customizable) |

| Plate Thickness | 5mm–10mm |

| Material Options | PP, PVC, SUS, Titanium, PTFE |

| Production Methods | Welding, Injection Molding, Integral Forming |

| Optional Features | pH/Temperature Control, Anti-Overflow Tanks, Water-Bath Jackets |

Why Choose Our Used Extraction Equipment?

- Cost Savings: Acquire high-performance systems at 30–50% lower costs than new equipment.

- Quality Assurance: Every unit undergoes rigorous inspection for corrosion resistance, structural integrity, and compliance.

- Quick Deployment: Pre-tested systems ship in 2–4 weeks, reducing downtime.

- Custom Upgrades: Integrate sensors (pH, liquid level) or automation controls post-purchase.

Material & Processing Excellence

Our refurbished extraction systems use durable materials like SUS (stainless steel) and PTFE for chemical resistance. Advanced techniques like CNC bending and robotic welding ensure precision.

Key Functions

- Adjustable agitator speeds for optimal phase separation.

- Anti-bubbling technology minimizes material loss.

- Modular tanks enable easy capacity expansion.

How It Works?

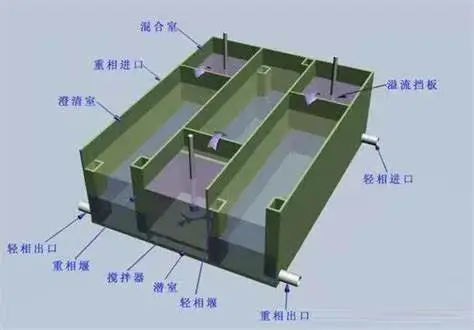

Used extraction equipment is a sophisticated piece of equipment that ingeniously combines two crucial processes: agitation for mixing and gravity - driven separation for settling. During the mixing phase, powerful agitators create a turbulent environment, ensuring thorough interaction between the substances involved. This is followed by the settling stage, where gravity takes over to separate the components based on their densities. What sets this mixer settler apart is its high degree of customizability. With adjustable interface heights, you can precisely control the separation boundary, while variable mixer speeds allow for optimized blending. This adaptability makes it ideal for processing materials such as lithium brine, where efficient extraction is key, or rare earth ores, enabling you to fine - tune the operation for maximum efficiency in any given application.

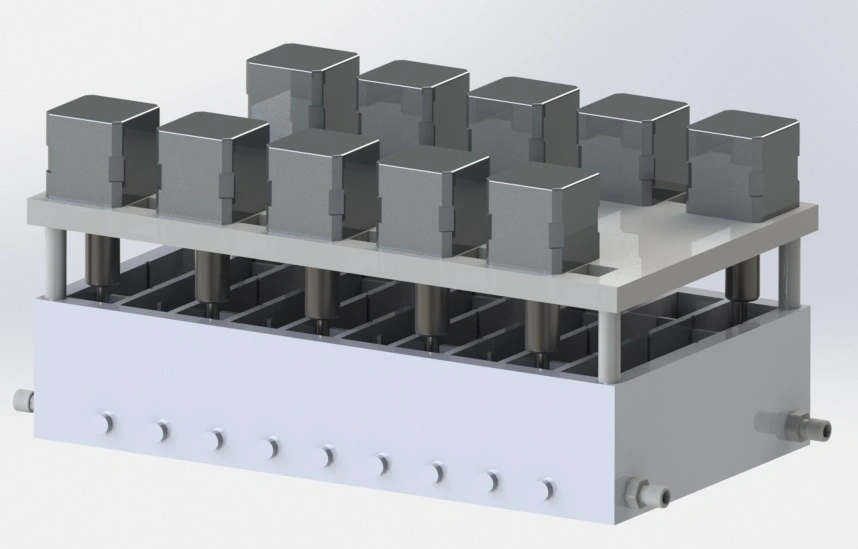

Physical Display

Discover the full potential of our equipment in an immersive way. You can explore every nook and cranny via our 360° videos. These videos provide a comprehensive view, allowing you to virtually walk around and examine the machinery from all angles, getting a feel for its size, shape, and overall design.

User Guide

- Installation: Bolt-on modules fit standard factory layouts.

- Operation: Pre-calibrated settings for common applications (e.g., nickel-cobalt extraction).

- Maintenance: Accessible components simplify cleaning and part replacement.

Applications

Ideal for:

- Rare Earth & Battery Recycling: Efficiently recover lithium, vanadium, or copper.

- Nuclear & Isotope Separation: Corrosion-resistant designs handle harsh chemicals.

- Pharmaceutical Extraction: Meet GMP standards with cleanable, modular units.

Support & Compliance

- Packaging: Crush-proof, moisture-resistant containers.

- After-Sales: 12-month warranty + remote troubleshooting.

- Certifications: CE, ISO 9001, and material safety reports provided.

FAQ

Q: What's the typical lifespan of your used extraction equipment?

A: Properly maintained units operate for 8–12 years. We provide lifespan estimates based on usage history.

Q: Can I modify the equipment post-purchase?

A: Yes! Our team offers retrofitting services for automation or sensor integration.

Q: Do you assist with import compliance?

A: We supply CE certificates, test reports, and customs documentation.

Q: How do I verify equipment condition?

A: Request third-party inspections (SGS/TÜV) or video demonstrations.

Q: What payment terms are available?

A: We accept LC, TT, or installment plans for orders above $20,000.

Contact Us

Upgrade your operations with cost-effective used extraction equipment tailored to your needs. Email wangzhijun@cuiyan-tec.com for quotes, technical specs, or a free consultation.