Liquid Liquid Extraction System

Configuration:desktop base edition, mobile standard edition, environmentally friendly high edition

Mixing volumn: 200ml, 300ml, 500ml, 1L, 2L, 3L or customized

Plate thickness:5mm,6mm,8mm,10mm

Material: PP,PPH,PVC,transparent PVC,PMMA,PTFE,PEEK,SUS,Ti

Production process: welding,bonding,bending,injection molding,integral forming

Optional function: temperature control device, pH adjustment device, water-bath jacket device, anti-overflow tank device,watch window device

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable mixer-settler stage amount, adjustable agitator speed, and adjustable phase interface height;Highly customizable

Application:rare earth extraction;nickel cobalt extraction;rubidium cesium extraction;salt lake brine extraction;nuclear extraction;isotope extraction;lithium battery recycling;vanadium battery recycling;copper electroplate recycling;biological wastewater recycling

- Product Description

Shaanxi Cuiyan: Your Trusted Liquid Liquid Extraction System Manufacturer & Supplier

Shaanxi Cuiyan Technology Co., Ltd, a trusted Liquid Liquid Extraction System manufacturer since 2012, specializes in lab-to-industrial equipment. Our systems blend automation, modular design, and customization to serve industries like chemical processing, lithium battery recycling, and rare earth extraction. With 300+ global clients and 10,000+ stages delivered, we ensure precision, durability, and compliance with your unique needs.

Liquid Liquid Extraction System Specifications

| Configuration | Desktop Base, Mobile Standard, Eco High Edition |

|---|---|

| Mixing Volume | 200mL–3L (Customizable) |

| Plate Thickness | 5–10mm |

| Material | PP, PVC, PTFE, SUS, Titanium, etc. |

| Production Process | Welding, Injection Molding, Integral Forming |

| Optional Features | pH Control, Anti-Overflow, Temperature Regulation |

Why Choose Our Liquid-Liquid Extraction System?

- ✅ Automation-Ready: Integrate with PLC/SCADA for precise phase separation.

- ✅ Energy-Saving Design: 20% lower energy use vs. conventional systems.

- ✅ Corrosion Resistance: SUS316L and PTFE options for harsh chemicals.

- ✅ Scalable**: Add stages or upgrade mixing speed as your lab grows.

Material & Processing Methods

We use PPH for acidic environments, PEEK for high-temperature stability, and titanium for nuclear applications. Processes like precision welding and injection molding ensure leak-free performance.

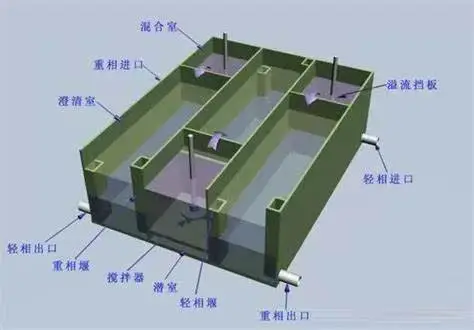

How it Works?

The Liquid Liquid Extraction System uses adjustable agitation to mix immiscible liquids (e.g., organic solvents and aqueous solutions). The settler layer then separates phases based on density, achieving >95% extraction efficiency. Optional sensors monitor pH, temperature, and interface height in real time.

Applications

Ideal for applications such as:

Rare earth refining、Lithium-ion battery recycling、Nuclear isotope separation、Pharmaceutical API extraction and Industrial wastewater treatment.

User Guide

- Mount the mixer - settler on a stable surface

Before initiating any operation, carefully choose a sturdy and level surface for mounting the mixer - settler unit. A stable base is imperative as it prevents vibrations that could disrupt the delicate separation processes within. Use appropriate mounting brackets or fixtures to securely fasten the unit. Ensure that the surface can bear the weight of the equipment, especially when it is filled with liquids during operation. This step is fundamental to guaranteeing the long - term, efficient performance of the mixer - settler. - Connect feed lines and set agitator speed (200–1500 RPM)

Once the unit is mounted, connect the feed lines with precision. Make sure the connections are tight to avoid any leaks that could lead to material loss or process inefficiencies. Afterward, turn your attention to the agitator speed setting. Using the control panel, select a speed within the 200 - 1500 RPM range. For less viscous liquids, a lower speed around 200 - 500 RPM might be sufficient for gentle mixing. However, for more viscous substances or when enhanced mass transfer is required, a higher speed like 1000 - 1500 RPM can be set. - Adjust phase interface via overflow weir

The phase interface within the mixer - settler plays a crucial role in the separation process. To adjust it, locate the overflow weir, which is designed to control the height of the liquid levels. By carefully modifying the position of the overflow weir, you can precisely set the interface between the two immiscible phases. This adjustment ensures optimal conditions for the separation of substances, maximizing the efficiency of the extraction or separation operation. Regularly monitor and fine - tune the phase interface as the process progresses. - Start automated cycles via touchscreen

With all the setup and adjustments complete, it's time to initiate the operation. Using the intuitive touchscreen interface, simply select the pre - programmed automated cycle that suits your specific process requirements. The touchscreen provides an easy - to - use platform where you can also monitor real - time data such as temperature, pressure, and the progress of the separation. Once started, the automated cycle will execute a series of operations, including mixing, settling, and separation, with minimal manual intervention, ensuring a consistent and efficient process.

Packaging

Shock-proof crates with humidity control.

Service

2-year warranty + lifetime technical support.

Certifications

ISO 9001, 12+ patents, REACH compliant.

FAQ

Q: Can you customize materials for corrosive solvents?

A: Yes! We offer PTFE-lined or titanium tanks for HCl, HNO3, and organic acids.

Q: Is the system compliant with FDA/CE standards?

A: All wetted parts meet FDA 21 CFR and CE PED directives.

Q: What's the lead time for a 500mL custom system?

A: Typically 4–6 weeks, including factory testing.

Q: Do you provide onsite training?

A: Yes – our engineers offer global installation support.

Q: Can I upgrade to automation later?

A: Absolutely! Our modular design allows IoT integration anytime.

Contact Us

Email wangzhijun@cuiyan-tec.com to discuss your Liquid Liquid Extraction System needs. Attach specs for a tailored quote!