Liquid Liquid Extractor

Configuration:desktop base edition, mobile standard edition, environmentally friendly high edition

Mixing volumn: 200ml, 300ml, 500ml, 1L, 2L, 3L or customized

Plate thickness:5mm,6mm,8mm,10mm

Material: PP,PPH,PVC,transparent PVC,PMMA,PTFE,PEEK,SUS,Ti

Production process: welding,bonding,bending,injection molding,integral forming

Optional function: temperature control device, pH adjustment device, water-bath jacket device, anti-overflow tank device,watch window device

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable mixer-settler stage amount, adjustable agitator speed, and adjustable phase interface height;Highly customizable

Application:rare earth extraction;nickel cobalt extraction;rubidium cesium extraction;salt lake brine extraction;nuclear extraction;isotope extraction;lithium battery recycling;vanadium battery recycling;copper electroplate recycling;biological wastewater recycling

- Product Description

Shaanxi Cuiyan: Your Trusted Liquid Liquid Extractor Manufacturer & Supplier

Shaanxi Cuiyan Technology Co., Ltd — a trusted liquid liquid extractor manufacturer & supplier since 2012 — combines cutting-edge engineering with 12+ years of industry expertise. Our lab-scale mixer settlers are praised for high corrosion resistance, modular scalability, and smart customization (e.g., integrated sensors, anti-bubbling tech). With 37+ skilled professionals and 300+ global clients, we deliver extraction solutions that align with your exact needs.

Liquid Liquid Extractor Description

Our lab-scale liquid liquid extractor is engineered for flexibility and precision across research, pilot, and industrial applications. Designed with adjustable mixing stages, agitator speeds, and phase interfaces, it supports seamless scaling from R&D to full production.

Specifications

| Category | Details |

|---|---|

| Configuration | Desktop Base, Mobile Standard, Eco-Friendly High Edition |

| Mixing Volume | 200mL–3L (Customizable) |

| Material Options | PP, PPH, PVC, PMMA, PTFE, SUS, Ti |

| Plate Thickness | 5mm–10mm |

| Production Process | Welding, Bonding, Injection Molding, Integral Forming |

| Optional Features | pH/Temperature Control, Anti-Overflow Tanks, Water-Bath Jackets, Watch Window |

Why Choose Our product?

✅ Automation Ready: Integrate PLC/DCS systems for precise control.

✅ Energy-Saving Design: Reduce operational costs by 20%+ with modular structures.

✅ Zero Leakage: Patented sealing tech ensures 99.9% leak-free operation.

✅ Rapid Scalability: Add/remove modules in <2 hours for process adjustments.

✅ Industry-Specific Customization: Tailor tanks, sensors, and materials (e.g., SUS316L for nuclear applications).

Material & Processing Excellence

Choose from 9+ corrosion-resistant materials, including titanium for acidic environments or transparent PVC for real-time monitoring. Our CNC-machined components and ISO-certified welding processes guarantee durability under extreme conditions (pH 1–14, ≤120°C).

Key Functions

- Adjust mixer-settler stages (1–10+).

- Monitor phase separation via glass/PMMA windows.

- Optimize extraction rates (≥95%) with variable agitator speeds (50–500 RPM).

- Add IoT-enabled sensors (pH, temperature, liquid level) for data-driven workflows.

How It Works?

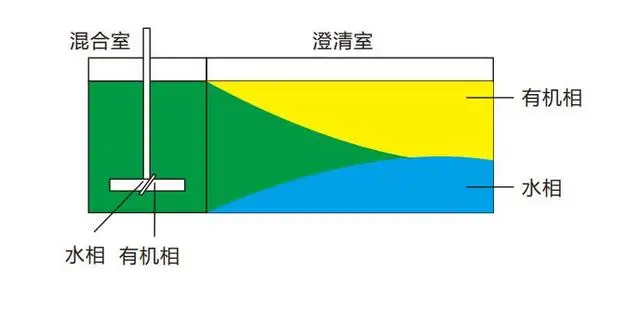

The liquid liquid extractor separates immiscible liquids through controlled mixing and settling. In the mixing chamber, dual-phase fluids blend thoroughly, while the settler tank leverages gravity for rapid phase separation. This process minimizes solvent loss and maximizes yield.

Physical Display

Our factory displays a full line of high-performance machines. You can view detailed photos to understand their capabilities.

User Guide

- Fill tanks with solvents

Begin the extraction process by carefully filling the designated tanks with the appropriate solvents. Select solvents based on their compatibility with the substances you aim to extract. Use calibrated measuring equipment to ensure accurate volumes, as the right solvent - to - feedstock ratio is crucial for efficient extraction. Pour the solvents slowly into the tanks, taking care to avoid spills. After filling, visually inspect the tanks to confirm there are no leaks and that the solvents are at the proper level. - Set mixing speed and phase height

Next, adjust the mixing speed according to the nature of the substances involved. A lower speed, around 50 - 100 RPM, might be suitable for delicate mixtures, while a higher speed, up to 300 - 500 RPM, could be needed for more viscous or stubborn compounds. Simultaneously, set the desired phase height using the control mechanisms on the equipment. This determines the interface between the two immiscible liquids during the extraction. Precise setting of these parameters maximizes the contact between the phases, enhancing the extraction efficiency. - Start extraction cycle (5–30 mins)

Once the mixing speed and phase height are set, initiate the extraction cycle. The cycle duration can range from 5 to 30 minutes, depending on factors like the complexity of the mixture and the solubility of the target compounds. During this time, the mixer - settler mechanism will continuously agitate the solvents and feedstock, promoting mass transfer between the phases. Monitor the process closely, either through visual inspection ports or via connected sensors that track parameters such as temperature and pressure to ensure a smooth extraction. - Collect separated phases via bottom valves

After the extraction cycle is complete, the separated phases can be collected. Open the bottom valves of the settler section of the equipment, starting with the valve for the denser phase, which typically settles at the bottom. Allow the denser phase to flow out into a collection vessel at a controlled rate. Once the denser phase is fully collected, switch to the valve for the lighter phase and collect it in a separate container. Make sure to label the collection vessels clearly to avoid confusion and ensure proper handling of the extracted substances.

Applications

- Pharma/Biotech: Purify APIs or plant extracts.

- Battery Recycling: Recover lithium, cobalt, or vanadium.

- Environmental: Remove heavy metals from wastewater.

- Metallurgy: Extract rare earths (e.g., neodymium, cerium).

Packaging & Transportation

Crate-protected, global door-to-door delivery.

After-Sales

2-year warranty + lifetime technical support.

FAQ

Q: Can I customize the extractor for high-pressure processes?

A: Yes! We offer reinforced PTFE/SUS316L units rated up to 10 bar.

Q: Do you provide compliance certifications?

A: All units include CE, ISO9001, and material safety reports.

Q: How often is maintenance needed?

A: Minimal upkeep – replace seals every 2 years under normal use.

Q: Can I expand capacity later?

A: Absolutely. Our modular design supports +50% capacity upgrades.

Q: What's the lead time?

A: Standard units ship in 2–4 weeks; custom orders take 6–8 weeks.

Contact Us

Email wangzhijun@cuiyan-tec.com to discuss your project. Let's engineer your extraction success with our Liquid Liquid Extractor!