Liquid Liquid Extraction Equipment

Configuration:desktop base edition, mobile standard edition, environmentally friendly high edition

Mixing volumn: 200ml, 300ml, 500ml, 1L, 2L, 3L or customized

Plate thickness:5mm,6mm,8mm,10mm

Material: PP,PPH,PVC,transparent PVC,PMMA,PTFE,PEEK,SUS,Ti

Production process: welding,bonding,bending,injection molding,integral forming

Optional function: temperature control device, pH adjustment device, water-bath jacket device, anti-overflow tank device,watch window device

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable mixer-settler stage amount, adjustable agitator speed, and adjustable phase interface height;Highly customizable

Application:rare earth extraction;nickel cobalt extraction;rubidium cesium extraction;salt lake brine extraction;nuclear extraction;isotope extraction;lithium battery recycling;vanadium battery recycling;copper electroplate recycling;biological wastewater recycling

- Product Description

Shaanxi Cuiyan: Your Trusted Liquid Liquid Extraction Equipment Manufacturer & Supplier

Established in 2012, Shaanxi Cuiyan Technology Co., Ltd specializes in advanced liquid liquid extraction equipment for lab, pilot, and industrial applications. With a team of 37 experts and over 300 global clients, we deliver high-efficiency, corrosion-resistant solutions tailored to industries like rare metal refining, lithium recycling, and environmental protection. Our equipment integrates automation, modular designs, and energy-saving innovations for unmatched performance.

Liquid Liquid Extraction Equipment Description

Our liquid liquid extraction equipment is engineered for precise separation of liquids in research and small-scale production. Designed with adaptability in mind, it supports customizable configurations to match your exact process requirements.

Specifications

| Specifications | Details |

|---|---|

| Configuration | Desktop Base, Mobile Standard, Eco High Edition |

| Mixing Volume | 200ml–3L (Customizable) |

| Plate Thickness | 5–10mm |

| Material Options | PP, PPH, PVC, SUS, Ti, PTFE, PMMA, PEEK |

| Production Process | Welding, Bonding, Injection Molding, Integral Forming |

| Optional Functions | Temperature Control, pH Adjustment, Anti-Overflow Tank, Watch Window |

Why Choose Our Liquid Liquid Extraction Equipment?

- High Extraction Efficiency: Achieve >95% separation accuracy with adjustable agitator speed and phase interface control.

- Leak-Proof Design: Robust construction using corrosion-resistant materials like PTFE or titanium ensures long-term durability.

- Modular Flexibility: Rapidly reconfigure stages or expand capacity for multi-process compatibility.

- Smart Customization: Integrate sensors (temperature, pH, liquid level) or water-jacketed heating for real-time monitoring.

Materials & Processing

- Corrosion Resistance: Choose SUS 316L for acidic environments or PP/PVC for cost-effective organic solvent handling.

- Transparency Options: PMMA or clear PVC tanks enable visual process tracking.

- Precision Manufacturing: Laser-cut plates and seamless welding eliminate leakage risks.

How It Works

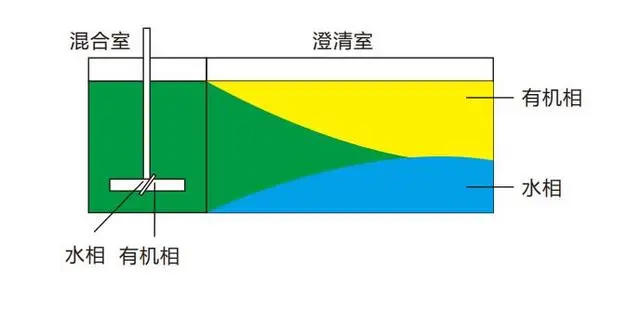

The mixer settler separates immiscible liquids via agitation (mixer) and gravity-based settling. Adjustable baffles optimize phase separation, while optional sensors automate pH or temperature adjustments. Ideal for extracting lithium from brine or recovering copper from electroplating waste.

Key Applications

- Rare Earth & Battery Recycling: Extract cobalt, nickel, or rubidium with minimal solvent loss.

- Nuclear & Pharmaceutical: Purify isotopes or APIs in controlled environments.

- Environmental Protection: Remove heavy metals from wastewater or recover organic solvents.

Physical Display

We offer detailed photo displays so you can experience our products in action.

User Guide

- Setup

When commencing the setup process, first identify a sturdy and level surface to mount the unit. A stable base is essential to prevent vibrations that could affect the equipment's performance. After securely mounting the unit, carefully connect the power cable, ensuring it is properly grounded to avoid electrical hazards. If you've opted for additional sensors, such as those for temperature or pressure monitoring, attach them following the provided wiring diagrams. This setup ensures that the unit is primed for accurate and efficient operation. - Calibration

Calibration begins with accessing the user - friendly digital interface. Here, you can precisely set the agitator speed within the range of 100 - 800 RPM. Consider the viscosity of the fluids you'll be processing. For thin, low - resistance liquids, a lower speed like 100 - 200 RPM might be sufficient for gentle mixing. However, for thicker, more viscous substances, a higher speed, perhaps 600 - 800 RPM, will be needed to ensure proper agitation and dispersion. - Operation

Once setup and calibrated, it's time for operation. Slowly load the appropriate fluids into the designated tanks, taking care not to overfill. Then, initiate the agitation process through the control panel. As the agitator starts working, observe the mixing and separation of the fluids through the sight window. This visual inspection allows you to monitor the progress, ensuring that the fluids are interacting as expected and that the separation process is occurring efficiently. - Maintenance

Maintenance is crucial for the long - term performance of the unit. After each use, thoroughly rinse the tanks with clean water or a recommended cleaning solution to remove any residue from the fluids. This prevents build - up that could affect future operations. Additionally, conduct a quarterly inspection of the seals. Look for signs of wear, such as cracks or leaks. If any issues are detected, replace the seals promptly to maintain the unit's integrity and prevent any potential fluid leaks.

Packaging & Transportation

Crush-proof foam and wooden cases ensure safe global delivery.

After-Sales Service

12-month warranty with 48-hour technical support.

Certifications

ISO 9001, CE, and 15+ patents.

FAQs

Q: Can this handle high-viscosity liquids?

A: Yes! Agitator torque adjusts to manage viscosities up to 1,500 cP.

Q: Is the equipment GMP-compliant?

A: SUS 316L models meet pharmaceutical-grade standards.

Q: Lead time for custom designs?

A: 4–6 weeks, depending on complexity.

Q: Can I upgrade an existing unit?

A: Absolutely—modular components allow easy retrofitting.

Q: Do you provide process optimization support?

A: Yes, our engineers offer free workflow analysis.

Contact Us

Elevate your extraction process with our lab-scale liquid liquid extraction equipment. Email wangzhijun@cuiyan-tec.com for quotes or technical consultations.