Liquid Liquid Extraction Unit

Configuration:desktop base edition, mobile standard edition, environmentally friendly high edition

Mixing volumn: 200ml, 300ml, 500ml, 1L, 2L, 3L or customized

Plate thickness:5mm,6mm,8mm,10mm

Material: PP,PPH,PVC,transparent PVC,PMMA,PTFE,PEEK,SUS,Ti

Production process: welding,bonding,bending,injection molding,integral forming

Optional function: temperature control device, pH adjustment device, water-bath jacket device, anti-overflow tank device,watch window device

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable mixer-settler stage amount, adjustable agitator speed, and adjustable phase interface height;Highly customizable

Application:rare earth extraction;nickel cobalt extraction;rubidium cesium extraction;salt lake brine extraction;nuclear extraction;isotope extraction;lithium battery recycling;vanadium battery recycling;copper electroplate recycling;biological wastewater recycling

- Product Description

Shaanxi Cuiyan: Your Trusted Liquid Liquid Extraction Unit Manufacturer & Supplier

Since 2012, Shaanxi Cuiyan Technology Co., Ltd has pioneered advanced liquid liquid extraction units for labs and industries. With 300+ global clients and 9,000+ stages sold, our equipment excels in automation, corrosion resistance, and modular customization. Backed by 10+ patented technologies, we deliver scalable solutions for rare metals, lithium recycling, and more.Our lab scale mixer settler adapts to diverse extraction workflows with precision.

Choose from three configurations:

Liquid Liquid Extraction Unit Specifications

| Specification | Details |

|---|---|

| Configurations | Desktop Base, Mobile Standard, Eco-Friendly High Edition |

| Mixing Volume | 200ml – 3L (Customizable) |

| Material Options | PP, PVC, PTFE, SUS, Titanium |

| Plate Thickness | 5mm – 10mm |

| Optional Features | Temperature Control, pH Sensors, Anti-Overflow Design, Watch Window |

Why Choose Our Liquid Liquid Extraction Unit?

✅ Tailored to Your Process

Customize agitator speeds, phase interfaces, and tank sizes for optimal separation.

✅ Energy-Saving & Modular

Combine units for scalability – ideal for pilot projects or multi-stage industrial setups.

✅ Zero Leaks, Zero Hassle

PTFE seals and anti-bubbling design ensure safe, clean operations.

✅ Smart Automation

Integrate IoT sensors (pH, temperature) for real-time data tracking.

Materials & Processing

- Durable Builds: SUS 316L for acidic environments, PTFE for extreme corrosion resistance.

- Precision Crafting: Laser-cut plates, robotic welding, and ISO-certified assembly.

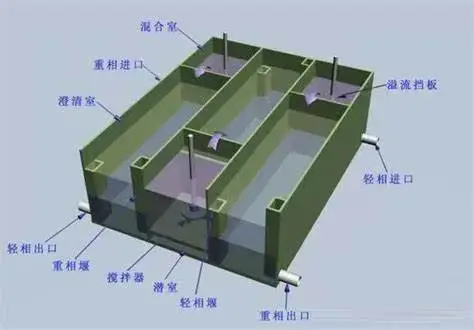

How It Works?

- Mixing: Agitators blend two immiscible phases for mass transfer.

- Settling: Gravity separates phases in clarifier zones.

- Collection: Adjustable weirs control interface levels for pure outputs.

Applications

- Rare Earths: Praseodymium/neodymium separation.

- Battery Recycling: Lithium, cobalt recovery from spent batteries.

- Pharma: API purification under GMP standards.

- Wastewater: Heavy metal removal (e.g., copper, vanadium).

Physical Display

Our high-performance liquid liquid extraction unit is presented with detailed visuals so you can see how they operate.

User Guide

- Setup

Begin the setup process by carefully selecting a stable benchtop location for the equipment. Mount the unit securely using the provided brackets to prevent any accidental tipping during operation. Next, connect the power cable, ensuring it is properly grounded to avoid electrical hazards. After power connection, focus on calibrating the sensors. Use standard calibration procedures and reference materials to fine - tune sensors that may measure temperature, pressure, or other critical parameters. A well - calibrated setup ensures accurate data collection and optimal performance. - Operation

Once the setup is complete, start the operation by accessing the touchscreen interface. Here, you can easily set the rotational speed (RPM) within the range of 100 - 1500. For less viscous substances, a lower RPM like 100 - 300 may be sufficient for gentle mixing. However, for more viscous materials or when enhanced agitation is required, increase the RPM up to 1500. Continuously monitor the process through the touchscreen, which displays real - time data such as temperature, pressure, and the status of the mixing operation. - Shutdown

When it's time to shut down the equipment, take advantage of the convenient one - step emptying function. This feature allows for quick and efficient draining of the substances inside. Simply activate the emptying mechanism through the control panel, and the system will drain all the contents into the designated receptacle. After draining, perform any necessary post - shutdown maintenance, such as cleaning the unit, to ensure it is ready for the next use.

Packaging & Transportation

Each unit is shock-proof packed with foam-lined crates. Global shipping available.

After-Sales Service

12-month warranty + lifetime technical support (email: jonywang@planseeextraction.com).

Certifications

ISO 9001, CE, and REACH compliant.

FAQ

Q: Can I upgrade my unit with new sensors later?

A: Yes! Our modular design allows retrofitting pH or temperature probes.

Q: Which material suits high-temperature extraction?

A: SUS 316L or titanium for >100°C processes.

Q: Lead time for custom orders?

A: 4–6 weeks for tailored configurations.

Q: Is training provided?

A: Free virtual training + PDF manual included.

Q: How to clean the mixer settler?

A: Use CIP (Clean-in-Place) function with solvent cycles.

Contact Us

Ready to optimize your extraction process? Email wangzhijun@cuiyan-tec.com for a quote or demo of liquid liquid extraction unit!