Multistage Liquid Liquid Extraction

Configuration:desktop base edition, mobile standard edition, environmentally friendly high edition

Mixing volumn: 200ml, 300ml, 500ml, 1L, 2L, 3L or customized

Plate thickness:5mm,6mm,8mm,10mm

Material: PP,PPH,PVC,transparent PVC,PMMA,PTFE,PEEK,SUS,Ti

Production process: welding,bonding,bending,injection molding,integral forming

Optional function: temperature control device, pH adjustment device, water-bath jacket device, anti-overflow tank device,watch window device

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable mixer-settler stage amount, adjustable agitator speed, and adjustable phase interface height;Highly customizable

Application:rare earth extraction;nickel cobalt extraction;rubidium cesium extraction;salt lake brine extraction;nuclear extraction;isotope extraction;lithium battery recycling;vanadium battery recycling;copper electroplate recycling;biological wastewater recycling

- Product Description

Shaanxi Cuiyan: Your Trusted Multistage Liquid Liquid Extraction Manufacturer & Supplier

Shaanxi Cuiyan Technology Co., Ltd. is a leading multistage liquid liquid extraction manufacturer and supplier with over a decade of expertise in designing lab-scale mixer settlers. Since 2012, we've delivered 10,000+ extraction stages to 300+ global clients, offering tailored solutions for industries like rare earth refining and pharmaceutical extraction. Our equipment integrates automation, corrosion-resistant materials, and modular designs to enhance separation efficiency while reducing costs.Our product are engineered for flexibility, scalability, and precision. Ideal for R&D or small-batch production, they ensure consistent phase separation and adaptability to diverse solvents.

Multistage Liquid Liquid Extractiont Specifications

| Specifications | Options |

|---|---|

| Configuration | Desktop Base Edition, Mobile Standard Edition, Environmentally Friendly High Edition |

| Mixing Volume | 200ml, 300ml, 500ml, 1L, 2L, 3L (Customizable) |

| Plate Thickness | 5mm, 6mm, 8mm, 10mm |

| Material | PP, PPH, PVC, Transparent PVC, PMMA, PTFE, PEEK, SUS, Ti |

| Production Process | Welding, Bonding, Bending, Injection Molding, Integral Forming |

| Optional Functions | Temperature Control, pH Adjustment, Water-Bath Jacket, Anti-Overflow Tank, Watch Window |

Why Choose Our Multistage Liquid Liquid Extraction Equipment?

- Customizable Design: Integrate sensors (pH, temperature) or choose specialized mixing/clarification tanks.

- Energy Efficiency: Modular structures reduce solvent waste, aligning with green chemistry goals.

- Durability: SUS/Ti materials offer unmatched corrosion resistance for aggressive chemicals.

- Automation: PLC-ready systems ensure precise phase interface control and repeatable results.

- Rapid Deployment: Modular units enable quick installation and scalability for evolving workflows.

Material & Processing: Built to Last

Select from PP for cost-effectiveness or PTFE/PEEK for high-temperature stability. Our advanced bonding and integral forming techniques eliminate leakage risks, even under high agitation speeds.

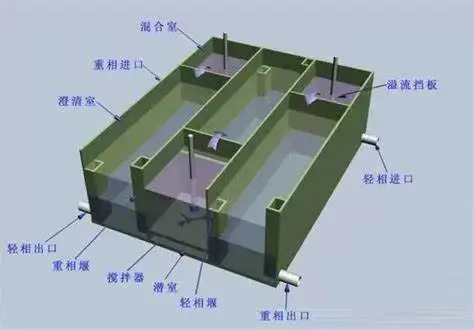

How product Works?

- Mixing Phase: Agitators blend two immiscible liquids, transferring target compounds.

- Settling Phase: Lighter/heavy phases separate in clarification zones, guided by adjustable weirs.

- Multi-Stage Flow: Configure stages in series for higher purity, with real-time interface monitoring.

Applications of product Systems

- Mining & Metals

- In the Mining & Metals industry, our multistage liquid liquid extraction is pivotal. For lithium extraction from brine, we use advanced evaporation and selective precipitation methods. This allows for efficient lithium recovery, essential for the booming battery market. Regarding cobalt and nickel recovery, complex hydrometallurgical processes are applied. These processes separate these valuable metals from ores, ensuring a sustainable supply for electronics and battery manufacturing.

- Pharmaceuticals

- In pharmaceuticals, our solutions play a crucial role. To purify APIs (Active Pharmaceutical Ingredients), we employ high - performance liquid chromatography and crystallization techniques. This guarantees the highest purity levels for safe and effective drugs. When isolating natural compounds, solvent extraction and membrane filtration are used. These methods help in harnessing the therapeutic potential of plants for new drug development.

- Environmental

- For environmental applications, especially in wastewater treatment, we focus on heavy metal extraction. Using ion - exchange resins and chemical precipitation, we target metals like lead, mercury, and cadmium. By removing these toxic heavy metals from industrial and municipal wastewater, we protect water bodies and human health, contributing to a cleaner environment.

- Energy

- In the energy sector, during uranium refinement, our advanced centrifugation and chemical separation processes ensure high - quality uranium for nuclear power generation. For battery recycling, whether it's Li - ion or vanadium batteries, we have developed processes to recover valuable metals. This reduces waste and provides a secondary source of materials for new battery production.

User Guide: Optimize Your Extraction Process

- Set agitator speeds between 200–800 RPM for optimal mixing without emulsification.

- Use watch windows to monitor phase separation dynamically.

- Pair with our pH adjustment module to stabilize sensitive compounds.

Packaging

Shock-proof crates with climate control for international shipping.

After-Sales

2-year warranty + spare parts guarantee.

Certifications

ISO 9001, CE, and 12+ patented technologies.

FAQ

Q:Can I customize the number of stages?

A:Yes! Configure 3–12 stages based on your separation factor requirements.

Q:Do your systems comply with FDA/GMP?

A:Absolutely. We provide documentation for pharmaceutical and food-grade applications.

Q:What's the lead time for orders?

A:Standard units ship in 2–4 weeks; customized designs take 6–8 weeks.

Q:Is technical support included?

A:Free lifetime remote support + optional on-site training.

Q:How does pricing compare to competitors?

A:We offer premium materials and automation at mid-range pricing, with 20% lower maintenance costs.

Contact Us

Elevate your extraction processes with Xi'an Plansee's multistage liquid liquid extraction equipment. Email wangzhijun@cuiyan-tec.com for a tailored solution or lab demo.