Bonding Mixer Settler

Configuration:desktop base edition, mobile standard edition, environmentally friendly high edition

Mixing volumn: 200ml, 300ml, 500ml, 1L, 2L, 3L or customized

Plate thickness:5mm,6mm,8mm,10mm

Material: PP,PPH,PVC,transparent PVC,PMMA,PTFE,PEEK,SUS,Ti

Production process: welding,bonding,bending,injection molding,integral forming

Optional function: temperature control device, pH adjustment device, water-bath jacket device, anti-overflow tank device,watch window device

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable mixer-settler stage amount, adjustable agitator speed, and adjustable phase interface height;Highly customizable

Application:rare earth extraction;nickel cobalt extraction;rubidium cesium extraction;salt lake brine extraction;nuclear extraction;isotope extraction;lithium battery recycling;vanadium battery recycling;copper electroplate recycling;biological wastewater recycling

- Product Description

Shaanxi Cuiyan: Your Trusted Bonding Mixer Settler Manufacturer & Supplier

Shaanxi Cuiyan Technology Co., Ltd: Your trusted bonding mixer settler manufacturer since 2012. With 37+ experts and 100+ patented technologies, we deliver lab-to-industrial extraction solutions featuring automation, corrosion resistance, and modular designs. Over 300 global clients rely on our equipment for precision, energy efficiency, and seamless scalability.

Bonding Mixer Settler Description

Our bonding mixer settler is engineered for liquid-liquid extraction processes, combining mixing and settling stages into a compact, leak-proof unit. Ideal for rare metals, lithium recycling, and wastewater treatment, it ensures high separation efficiency with minimal maintenance.

Specifications

| Specifications | Options |

|---|---|

| Configuration | Desktop base, Mobile standard, Eco-friendly high edition |

| Mixing Volume | 200mL–3L (Customizable) |

| Plate Thickness | 5mm–10mm |

| Material | PP, PVC, SUS, Ti, PTFE, PMMA |

| Production Process | Welding, Bonding, Injection Molding, Integral Forming |

| Optional Functions | Temperature/pH control, Anti-overflow, Water-jacket, View window |

Why Choose Our product?

- Zero Leakage: Advanced bonding techniques eliminate leakage risks.

- Customizable: Adjust mixing speed, stage count, and interface height.

- Corrosion-Resistant: SUS/Ti materials handle acidic/alkaline media.

- Energy-Saving: Modular design reduces power consumption by 15–20%.

Material & Processing

- Durable Polymers: PP/PVC for cost-effective chemical resistance.

- High-Performance Alloys: SUS 316L/Ti for extreme pH/heat conditions.

- Precision Crafting: Laser-cut plates and robotic welding ensure <0.1mm tolerance.

How It Works

- Mixing Stage: Agitators blend two immiscible liquids for mass transfer.

- Settling Zone: Gravity separates phases within minutes.

- Interface Control: Adjustable weirs maintain stable separation layers.

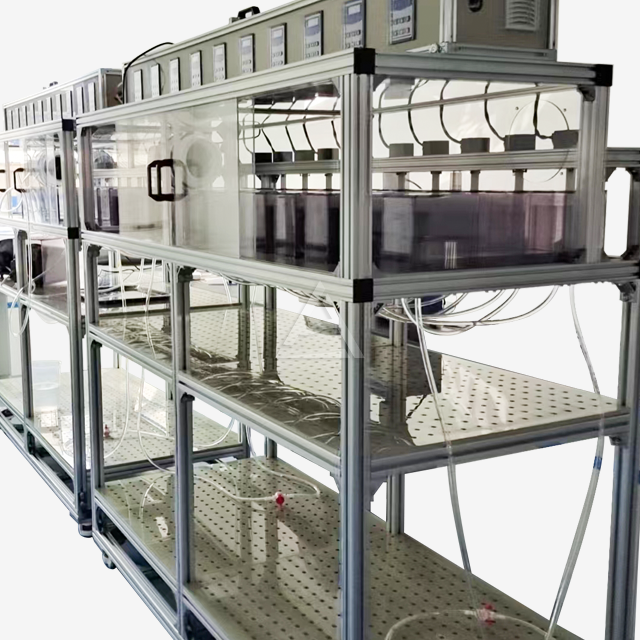

Physical Display

We're displaying actual bonding mixer settler. The clear photos allow you to see them in detail. Let us know if you need more information or have any questions.

User Guide

- Setup: Connect feed lines and configure sensors (pH/temperature).

- Calibration: Set agitator speed (200–800 RPM) via touchscreen.

- Maintenance: Clean tanks weekly; replace seals annually.

Applications

- Metals: Rare earth, nickel-cobalt, rubidium-cesium extraction.

- Recycling: Lithium batteries, vanadium flow cells, copper electroplating.

- Environmental: Heavy metal wastewater, nuclear residue treatment.

Packaging & Shipping

Our packaging and shipping solutions are designed to safeguard your products during transit. We use shock - proof crates constructed with multi - layer, high - density foam inserts. These inserts cushion the item, absorbing any impact from jolts or drops. To further enhance security, we integrate GPS tracking technology. This allows you to monitor the real - time location of your shipment, ensuring peace of mind. Whether it's delicate electronics or valuable machinery, our packaging and shipping services guarantee safe and traceable delivery.

After - Sales

We pride ourselves on providing comprehensive after - sales support. With 24/7 remote support, our team of experts is always on standby. You can reach out via phone, email, or live chat for immediate assistance. Whether it's troubleshooting a technical issue or answering product - related questions, we're here to help. Additionally, we offer a 2 - year warranty. This means that if your product develops a defect within this period, we'll repair or replace it at no cost, demonstrating our commitment to your satisfaction.

Certifications

Our commitment to quality and compliance is reflected in our multiple certifications. ISO 9001 certifies that we have a robust quality management system in place, ensuring consistent product quality. The CE mark indicates that our products meet strict European health, safety, and environmental protection standards. RoHS compliance means that our products are free from hazardous substances, such as lead and mercury. These certifications are a testament to our dedication to producing high - quality, safe, and environmentally friendly products.

FAQs

Q: Can this handle explosive solvents?

A: Yes—explosion-proof motors and PTFE coatings are optional.

Q: What's the lead time for a 500L custom unit?

A: 6–8 weeks after design approval.

Q: Is training provided?

A: Free onsite/online training included.

Q: How to scale up from lab to production?

A: Our modular design allows stage additions in <48 hours.

Q: Do you offer turnkey solutions?

A: Yes—process design, equipment, and automation bundled.

Contact Us

Email: wangzhijun@cuiyan-tec.com

Customize your bonding mixer settler today—click here for a quote!