Rare Earth Industry Mixer Settler

Cooperation solution: labor+material contracting,labor-ony contracting

Mixing volumn: 100L,200L,300L,500L,800L,1000L or customized

Plate thickness:12mm,15mm,20mm,25mm,30mm

Material: PP,PPH,PVC,transparent PVC

Production process: welding

Optional function: temperature control device,pH adjustment device,anti-overflow tank device

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable agitator speed,adjustable phase interface height

Application: rare earth extraction;nickel cobalt extraction;rubidium cesium extraction;salt lake brine extraction;nuclear extraction;lithium battery recycling;vanadium battery recycling;copper electroplate recycling;biological wastewater recycling

- Product Description

Shaanxi Cuiyan: Your Trusted Rare Earth Industry Mixer Settler Manufacturer & Supplier

Shaanxi Cuiyan Technology Co., Ltd, established in 2012, specializes in designing and manufacturing industrial-scale rare earth industry mixer settlers. With over 300 global clients and 10,000+ equipment stages delivered, our mixer settlers combine automation, corrosion resistance, and modular flexibility to optimize rare earth extraction processes. Trusted by leading mining and recycling enterprises, we ensure precision, durability, and compliance with global standards.

Rare Earth Industry Mixer Settler Description

Our rare earth industry mixer settler is engineered for high-volume separation of rare earth elements, such as neodymium, dysprosium, and cerium. Designed to handle corrosive solvents and harsh operating conditions, they streamline extraction workflows while minimizing energy consumption.

Specifications

| Parameter | Details |

|---|---|

| Mixing Volume | 100L–1000L (Customizable) |

| Plate Thickness | 12mm–30mm |

| Material | PP, PPH, PVC, Transparent PVC |

| Production Process | Welding |

| Optional Functions | Temperature Control, pH Adjustment, Anti-Overflow |

Why Choose Our Rare Earth Industry Mixer Settler?

- 98% Extraction Rate: Advanced phase separation for maximum yield.

- Zero-Leak Guarantee: Robust welding and pressure testing.

- Smart Automation: Integrated sensors for real-time monitoring.

- Modular Scalability: Expand capacity without downtime.

Material & Processing Method

Constructed with corrosion-resistant PP or PVC, our equipment withstands acidic/alkaline environments. Precision welding ensures structural integrity, while transparent PVC models allow visual process inspection.

How It Works

- Mixing Stage

In the mixing stage, high - performance agitators play a crucial role. These agitators are equipped with specialized impellers designed to efficiently blend the organic and aqueous phases. As they rotate, they create turbulence, which maximizes the contact area between the two immiscible liquids. This enhanced interaction promotes mass transfer, allowing for the effective exchange of substances between the phases. Whether it's in a chemical extraction process or a pharmaceutical formulation, the agitators ensure a thorough and homogeneous mixing, setting the stage for subsequent separation. - Settling Stage

Once the mixing is complete, the settling stage takes over. Gravity becomes the driving force here, as it acts on the mixture to separate the phases based on their density differences. The heavier phase, whether it's the aqueous or organic layer depending on the substances involved, gradually sinks to the bottom of the settling vessel. Meanwhile, the lighter phase rises to the top. This natural separation process occurs over time, and the clear demarcation between the two phases is essential for their subsequent collection and further processing. - Continuous Flow

To maintain a seamless operation, automated pumps are employed to regulate the throughput. These pumps are programmed to precisely control the flow rate of the mixture into the mixing stage and the separated phases out of the settling stage. By adjusting the pump speed and flow parameters, operators can ensure a continuous and steady process. This not only increases efficiency but also allows for better control over the overall operation, whether it's a small - scale laboratory setup or a large - scale industrial production line.

Applications

Ideal for rare earth mining, lithium battery recycling, and nuclear waste treatment. Also used in:

- Nickel-Cobalt Hydrometallurgy

- Salt Lake Lithium Extraction

- Biomedical Waste Purification

User Guide

Pre-installation checks, agitator speed calibration, and phase interface adjustments are simplified with our step-by-step manual. Remote training sessions available.

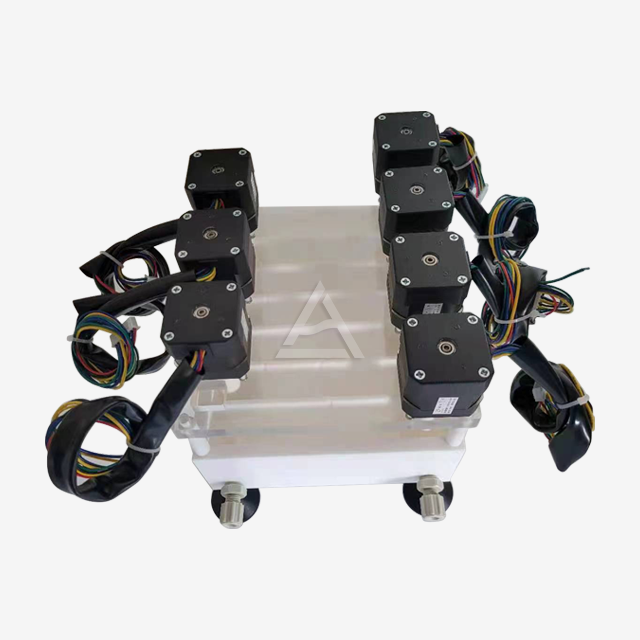

Physical Display

These are actual rare earth industry mixer settler showcases. You can get a visual sense through the provided images. We're available to share more details and answer your questions anytime.

Packaging

Wooden crates with shockproof foam.

Certifications

ISO 9001, CE.

Warranty

5-year limited.

FAQ

Q:Can you customize agitator configurations?

A:Yes—specify RPM ranges, blade designs, or sensor integrations.

Q:What's the lead time for 500L models?

A:4–6 weeks, including testing and documentation.

Q:Do you comply with EU REACH regulations?

A:All materials meet EU/US chemical safety standards.

Contact Us

Email wangzhijun@cuiyan-tec.com for quotes, technical drawings, or site audits of Rare Earth Industry Mixer Settler.