PP Mixer Settler

Configuration:desktop base edition, mobile standard edition, environmentally friendly high edition

Mixing volumn: 200ml, 300ml, 500ml, 1L, 2L, 3L or customized

Plate thickness:5mm,6mm,8mm,10mm

Material: PP,PPH,PVC,transparent PVC,PMMA,PTFE,PEEK,SUS,Ti

Production process: welding,bonding,bending,injection molding,integral forming

Optional function: temperature control device, pH adjustment device, water-bath jacket device, anti-overflow tank device,watch window device

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable mixer-settler stage amount, adjustable agitator speed, and adjustable phase interface height;Highly customizable

Application:rare earth extraction;nickel cobalt extraction;rubidium cesium extraction;salt lake brine extraction;nuclear extraction;isotope extraction;lithium battery recycling;vanadium battery recycling;copper electroplate recycling;biological wastewater recycling

- Product Description

Shaanxi Cuiyan: Your Trusted PP Mixer Settler Manufacturer & Supplier

Shaanxi Cuiyan Technology Co., Ltd, a leading PP mixer settler manufacturer & supplier since 2012, combines cutting-edge engineering with 12+ years of expertise in solvent extraction technology. Our equipment excels in corrosion resistance, energy efficiency, and modular customization, serving 300+ global clients across mining, chemical, and environmental sectors.

PP Mixer Settler Description

The PP mixer settler is a compact, high-performance extraction system designed for lab-scale separation of rare metals, lithium, and industrial wastewater components. Its modular structure supports flexible process adjustments while maintaining leak-proof operation.

Specifications

| Parameter | Details |

|---|---|

| Mixing Volume | 200ml, 300ml, 500ml, 1L, 2L, 3L, or customized |

| Plate Thickness | 5mm, 6mm, 8mm, 10mm |

| Material Options | PP, PPH, PVC, Transparent PVC, PMMA, PTFE, SUS, Ti |

| Production Process | Welding, Bonding, Bending, Injection Molding, Integral Forming |

| Optional Functions | Temperature Control, pH Adjustment, Anti-Overflow Tank, Watch Window |

Why Choose Our product?

- Customizable Design: Adapt mixing stages, agitator speed, and phase interface height for unique workflows.

- Superior Materials: PP and PTFE options ensure resistance to acids, alkalis, and high-temperature solvents.

- Energy Efficiency: 30% lower power consumption than traditional models, aligning with green chemistry goals.

Material & Processing Excellence

- PP (Polypropylene): Ideal for corrosive environments (pH 1–14) with a lifespan of 8–10 years.

- PTFE Lining: Enhances durability for nuclear or high-purity applications.

- Precision Fabrication: Laser-cut components and ultrasonic welding ensure zero leakage.

Key Functions

- Anti-Bubbling Design: Stable phase separation even at 1,200 rpm agitation.

- One-Step Tank Filling/Emptying: Reduces operational downtime by 40%.

- Integrated Sensors: Monitor pH, temperature, and liquid levels in real time.

How It Works?

- Mixing Stage: The agitator blends two immiscible phases (e.g., organic solvent and metal-rich aqueous solution).

- Settling Zone: Laminar flow design accelerates phase separation within 2–5 minutes.

- Continuous Extraction: Adjustable weirs enable multistage purification without cross-contamination.

Applications

- Metallurgy:Metallurgy in the context of rare earth, nickel, cobalt, and rubidium extraction is a complex and crucial process. Rare earth elements, despite their name, are relatively abundant in the Earth's crust but often dispersed. Specialized mining techniques are employed to extract them. Nickel and cobalt, essential for battery manufacturing and various high - tech applications, are obtained through methods like sulfide ore smelting. Rubidium, with its unique properties in electronics and atomic clocks, requires precise extraction from minerals. Advanced chemical separation processes are then used to purify these elements, ensuring high - quality products for industries ranging from clean energy to aerospace.

- Battery Recycling:Battery recycling, specifically the recovery of lithium, vanadium, and copper from e - waste, has become increasingly important due to the growing demand for batteries in electric vehicles and portable electronics. Lithium, a key component in lithium - ion batteries, can be retrieved through processes such as acid leaching and precipitation. Vanadium, used in vanadium redox flow batteries, is extracted by treating e - waste with appropriate reagents to separate it from other materials. Copper, which is present in large quantities in battery components, is recovered through methods like smelting and electrorefining. This not only reduces the need for virgin mining but also helps in minimizing environmental pollution associated with e - waste disposal.

- Environmental:The removal of heavy metals such as lead and arsenic from industrial wastewater is a vital aspect of environmental protection. Lead, a highly toxic metal, can cause severe health problems, and arsenic is also a known carcinogen. To remove them, various treatment methods are used. Chemical precipitation involves adding reagents to the wastewater to form insoluble metal compounds that can be separated. Ion - exchange processes use resins to selectively remove heavy metal ions. Biological methods, such as the use of certain bacteria, can also be effective in binding and removing these metals. By treating industrial wastewater, we can prevent the contamination of water bodies, protect aquatic life, and safeguard human health.

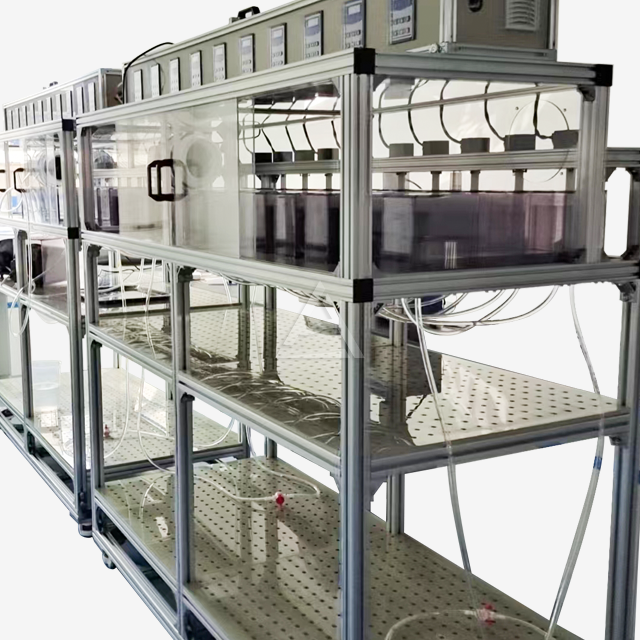

Physical Display

This is a live PP mixer settler display. The images clearly show the physical look of the equipment. Contact us for further details anytime.

User Guide

- Setup:Begin by securely mounting the base unit in a stable location, ensuring all connections are tight. Then, carefully connect the various sensors according to the wiring diagram. Next, calibrate the agitator speed. This is crucial as it affects the mixing efficiency. Adjust the speed within the range of 200–1,200 revolutions per minute (rpm) using the control panel.

- Operation:Once setup is complete, load the required solutions into the appropriate chambers. Be cautious not to overfill. To set the phase interface height, utilize the adjustable overflow plates. This allows for precise control over the separation process. Adjust them according to the specific requirements of the solutions being processed.

- Maintenance:After each use, it's essential to rinse the equipment thoroughly with deionized water. This helps prevent residue build - up that could affect future operations. Additionally, conduct a quarterly inspection of the seals. Check for any signs of wear, leakage, or damage. Replace seals immediately if any issues are detected to maintain the integrity of the system.

FAQ

Q: Can this product handle radioactive materials?

A: Yes! PTFE-lined units meet ISO Class 5 cleanliness for nuclear applications.

Q: What certifications do you hold?

A: We're ISO 9001, CE, and REACH certified, with ASME-compliant designs available.

Q: Is on-site installation support provided?

A: Global clients receive remote setup guides or optional technician dispatch.

Q: How long does customization take?

A: Standard lead time is 4–6 weeks; expedited options reduce this to 2 weeks.

Q: Do you offer scalability for pilot-to-production transitions?

A: Absolutely! Modular units allow seamless capacity expansion up to 500 L/hr.

Contact Us

Elevate your extraction processes with a PP mixer settler built for precision and reliability. Email wangzhijun@cuiyan-tec.com for quotes, technical specs, or a free process review.