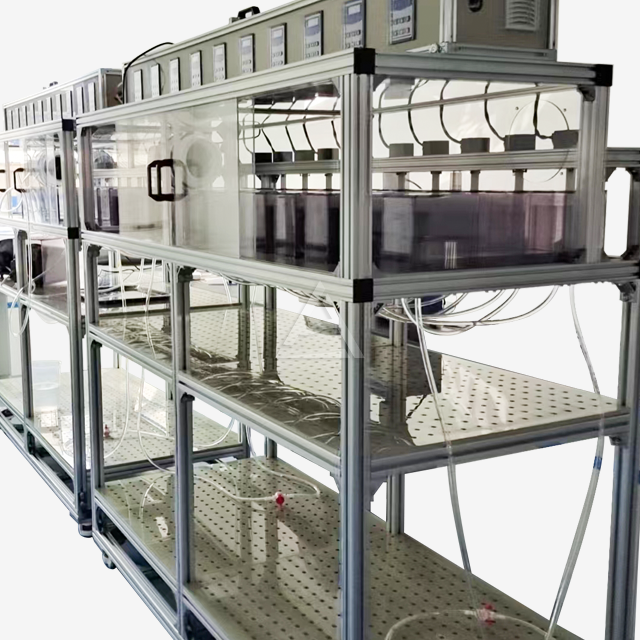

Pilot Liquid Liquid Extraction

Configuration:mobile platform edition, skid mounted edition

Mixing volumn: 8L,10L,20L,40L,60L,80L or customized

Plate thickness:8mm,10mm,12mm,15mm

Material: PP,PPH,PVC,transparent PVC,PMMA

Production process: welding,bonding

Optional function: temperature control device, pH adjustment device, anti-overflow tank device,watch window device

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable mixer-settler stage amount, adjustable agitator speed, and adjustable phase interface height;Highly customizable

Application:rare earth extraction;nickel cobalt extraction;rubidium cesium extraction;salt lake brine extraction;nuclear extraction;vanadium battery recycling;copper electroplate recycling;biological wastewater recycling

- Product Description

Shaanxi Cuiyan: Your Trusted Pilot Liquid Liquid Extraction Manufacturer & Supplier

As a leading Pilot Liquid Liquid Extraction manufacturer since 2012, Shaanxi Cuiyan Technology Co., Ltd combines cutting-edge modular designs with 10+ years of industrial expertise. Our systems are trusted by 300+ global clients across chemical, pharmaceutical, and environmental sectors for their corrosion resistance, scalability, and seamless automation integration.

Pilot Liquid Liquid Extraction Overview

Our Pilot Liquid Liquid Extraction units bridge lab research and full-scale production, offering precise phase separation and adaptable configurations for diverse solvent systems.

Specifications

| Parameter | Options/Capacity |

|---|---|

| Configuration | Mobile Platform, Skid-Mounted |

| Mixing Volume | 8L–80L (Customizable) |

| Plate Thickness | 8mm–15mm |

| Material | PP, PPH, PVC, PMMA |

| Production Process | Welding, Bonding |

| Optional Functions | Temperature/pH control, Anti-overflow tank, Observation window |

Why Choose Our Pilot Liquid Liquid Extraction System?

- Proven Efficiency – Achieve >95% extraction rates with optimized mixing-clarification cycles.

- Future-Ready Design – Modular components allow easy capacity expansion (e.g., 20L→80L upgrades).

- Smart Integration – Pre-installed sensor ports for real-time monitoring (temperature, pH, interface levels).

Advanced Materials & Processing

- Corrosion-Resistant Builds: PPH welding for acidic environments (e.g., nickel-cobalt recovery).

- Transparent PMMA Tanks: Ideal for visual process validation in R&D labs.

- ISO-Certified Fabrication: Laser-aligned baffles ensure uniform flow distribution.

Key Functional Advantages

- Bubble-Free Operation: Patented dispersion technology prevents emulsification.

- One-Step Tank Management: Rapid filling/emptying reduces batch cycle time by 30%.

- Speed-Adjustable Agitators: 50–1,200 rpm control for shear-sensitive materials.

How It Works

- Mixing Stage: Dual impellers create controlled turbulence for optimal mass transfer.

- Settling Zone: Tilted plate stacks enable rapid (<5 mins) organic/aqueous phase separation.

- Interface Control: Adjustable weirs maintain stable phase boundaries.

Industry Applications

- Rare Earths: High-purity La/Ce/Pr/Nd separation.

- Battery Recycling: Li/Co/Mn extraction from spent lithium-ion cells.

- Pharmaceuticals: API intermediate purification (ICH Q7 compliant).

- Wastewater Treatment: Phenol/Heavy metal recovery (meets EPA 40 CFR standards).

User Guide

- Step 1: Select tank material based on solvent compatibility (e.g., PVC for kerosene - HCl systems)

When choosing a tank material, solvent compatibility is of utmost importance. Different solvents can have varying chemical reactions with materials, which may lead to corrosion, swelling, or degradation. For a kerosene - HCl system, PVC (Polyvinyl Chloride) is a suitable choice. Kerosene, being a hydrocarbon, and HCl, a strong acid, do not react aggressively with PVC. PVC's chemical resistance properties ensure that the tank remains intact, preventing leaks and maintaining the integrity of the substances stored within. This selection process safeguards the longevity of the tank and the safety of the overall operation. - Step 2: Set mixer RPM via touchscreen (preset profiles available)

The touchscreen interface provides an easy - to - use method for setting the mixer's revolutions per minute (RPM). This precision control is crucial as the optimal RPM depends on factors such as the viscosity of the substances being mixed and the nature of the mixing process. If you're dealing with a highly viscous liquid, a higher RPM might be required to ensure proper blending. Additionally, the availability of preset profiles simplifies the process. These profiles are pre - configured based on common mixing scenarios, allowing operators to quickly select the appropriate RPM settings with just a few taps on the touchscreen, saving time and ensuring consistent results. - Step 3: Monitor phase separation via sight glasses; adjust weir height as needed

Sight glasses offer a direct view of the phase separation process within the tank. By observing through these glasses, operators can determine how effectively the immiscible phases are separating. If the separation is not occurring as expected, one possible adjustment is to modify the weir height. The weir controls the flow and level of the liquid phases. Lowering the weir can increase the flow rate of the lighter phase, potentially enhancing separation. Conversely, raising the weir may slow down the flow and allow for more time for the phases to separate. Regular monitoring and appropriate weir adjustments are essential for achieving high - quality phase separation.

Technical Support & Services

- Packaging: Shock-proof crates with humidity-controlled desiccant.

- Delivery: Global shipping via DHL/FedEx (15–25 days).

- Warranty: 3-year coverage on mechanical parts + lifetime email/remote support.

FAQ

Q1: Can this handle high-viscosity solutions like ionic liquids?

A: Yes—our turbine agitators support viscosities up to 5,000 cP.

Q2: Is the system compatible with ATEX Zone 1?

A: Optional explosion-proof motors and control cabinets are available.

Q3: How to clean residual organics between batches?

A: Integrated CIP (Clean-in-Place) nozzles simplify solvent flushing.

Q4: What data outputs are provided?

A: CSV/OPC UA formats for flow rates, extraction efficiency, and energy consumption.

Q5: Can we test our feedstock before purchase?

A: Absolutely—we offer free 20L sample processing trials.

Contact Us

For more information about our Pilot Liquid Liquid Extraction, including pricing, customization options, and bulk orders, please feel free to reach out to us:Email at wangzhijun@cuiyan-tec.com