Pilot Solvent Extraction

Configuration:mobile platform edition, skid mounted edition

Mixing volumn: 8L,10L,20L,40L,60L,80L or customized

Plate thickness:8mm,10mm,12mm,15mm

Material: PP,PPH,PVC,transparent PVC,PMMA

Production process: welding,bonding

Optional function: temperature control device, pH adjustment device, anti-overflow tank device,watch window device

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable mixer-settler stage amount, adjustable agitator speed, and adjustable phase interface height;Highly customizable

Application:rare earth extraction;nickel cobalt extraction;rubidium cesium extraction;salt lake brine extraction;nuclear extraction;vanadium battery recycling;copper electroplate recycling;biological wastewater recycling

- Product Description

Shaanxi Cuiyan: Your Trusted Pilot Solvent Extraction Manufacturer & Supplier

Shaanxi Cuiyan Technology Co., Ltd, established in 2012, specializes in designing and manufacturing pilot solvent extraction systems for industries like mining, pharmaceuticals, and environmental protection. With 37+ experts and 9,000+ equipment stages delivered globally, our solutions combine automation, energy efficiency, and modular scalability to meet your unique process needs.

Pilot Solvent Extraction Description

Our pilot solvent extraction bridges lab research and industrial production, offering flexible configurations for solvent extraction, phase separation, and resource recovery.

Specifications

| Specifications | Options |

|---|---|

| Configuration | Mobile platform edition, skid-mounted edition |

| Mixing Volume | 8L, 10L, 20L, 40L, 60L, 80L, or customized |

| Plate Thickness | 8mm, 10mm, 12mm, 15mm |

| Material | PP, PPH, PVC, transparent PVC, PMMA |

| Production Process | Welding, bonding |

| Optional Functions | Temperature control, pH adjustment, anti-overflow tank, viewing window |

Why Choose Our Pilot Solvent Extraction Equipment?

- Precision Automation: Integrated sensors (temperature, pH, liquid level) enable real-time monitoring for consistent results.

- Anti-Bubbling Design: One-step filling/emptying reduces operational downtime.

- Energy-Saving Modularity: Adaptable to green chemistry workflows with quick installation and expansion.

- Industry-Specific Customization: Dedicated tanks for rare earth, nuclear, or battery recycling applications.

- Proven Expertise: 12+ patented technologies and 300+ successful projects worldwide.

Material & Processing

- Corrosion-Resistant Materials: PP, PVC, and PMMA ensure compatibility with acidic/organic solvents.

- Robust Construction: Laser-cut plates (8–15mm thickness) with welded or bonded joints for leak-proof operation.

How It Works

- Mixing Stage: Agitators blend solvents and feedstock to transfer target compounds.

- Settling Stage: Phase separation occurs in clarified zones, with adjustable interface height for optimal recovery.

- Automated Control: Sensors regulate speed, temperature, and flow rates for repeatable performance.

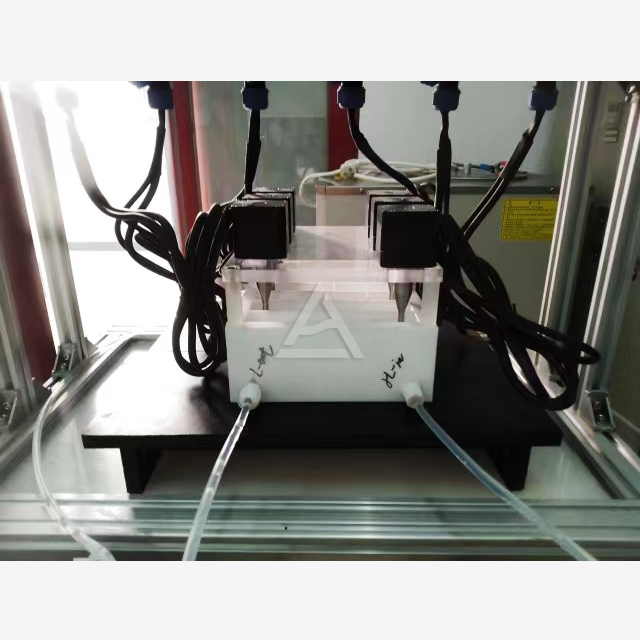

Physical Display

You're viewing real pilot solvent extraction displays. The detailed images help you understand their design and function. We're happy to assist with any questions you may have.

User Guide

- Setup: Mount the mixer-settler on a stable platform and connect sensors.

- Calibration: Adjust agitator speed (0–500 RPM) using the touchscreen interface.

- Operation: Load feedstock, start the automated cycle, and collect separated phases.

Application Areas

- Metals

In the realm of metals, recycling is of utmost importance. For rare earth elements, used in high - tech applications like electronics and clean energy, recycling involves extracting them from end - of - life products. Nickel and cobalt, crucial for batteries, are reclaimed from spent batteries through chemical leaching and separation techniques. Rubidium and cesium, with applications in atomic clocks and medical imaging, can be recycled from specific industrial waste. Vanadium, a key component in vanadium redox flow batteries, is recovered to promote a circular economy in the energy storage sector. - Environmental

Environmental treatment processes focus on sustainable resource management. Salt lake brine treatment aims to extract valuable minerals, such as lithium, in an environmentally friendly way. Copper electroplating wastewater contains heavy metals and harmful chemicals. Treatment methods like chemical precipitation and ion - exchange are used to remove copper and other contaminants before discharge. Bio - waste treatment involves converting organic waste into useful products, such as biogas through anaerobic digestion, reducing landfill waste and generating renewable energy. - Energy & Pharma

In the energy and pharmaceutical sectors, specialized processes are in place. Nuclear solvent recovery is crucial for handling radioactive materials safely. Solvents used in nuclear fuel reprocessing are recovered and recycled to minimize waste and ensure safety. In the pharmaceutical industry, API (Active Pharmaceutical Ingredient) purification is a multi - step process. It often involves techniques like chromatography and crystallization to remove impurities, ensuring that the final drugs are of high quality and safe for human consumption.

Packaging & Transportation

Crate-protected with shock-absorbent materials for global shipping.

After-Sales Service

1-year warranty, lifetime maintenance support, and free process optimization consulting.

Certifications

ISO 9001, CE, 12+ national patents.

FAQ

Q: Can you customize extraction stages for my specific process?

A: Yes! We design mixer-settlers with adjustable stage counts and tank geometries.

Q: Are your systems certified for hazardous environments?

A: All equipment meets ISO 9001 and CE standards. GMP-ready options available.

Q: What's the lead time for a skid-mounted unit?

A: Standard units ship in 4–6 weeks; custom designs require 8–10 weeks.

Q: Do you provide remote technical support?

A: 24/7 assistance via email or video call for troubleshooting.

Q: Can I upgrade my system for larger volumes later?

A: Absolutely—our modular design allows seamless capacity expansion.

Contact Us

Ready to optimize your solvent extraction? Email wangzhijun@cuiyan-tec.com for a tailored quote of Pilot Solvent Extraction!

VIEW MOREPMMA Mixer Settler

VIEW MOREPMMA Mixer Settler VIEW MORECounter Current Liquid Liquid Extraction

VIEW MORECounter Current Liquid Liquid Extraction VIEW MOREMixer Settler Equipment

VIEW MOREMixer Settler Equipment VIEW MOREMixer Settler For Liquid Liquid Extraction

VIEW MOREMixer Settler For Liquid Liquid Extraction VIEW MORESingle Stage Mixer Settler

VIEW MORESingle Stage Mixer Settler VIEW MOREBiological Wastewater Industry Mixer Settler

VIEW MOREBiological Wastewater Industry Mixer Settler VIEW MOREMicro Mixer Settler Unit

VIEW MOREMicro Mixer Settler Unit VIEW MORELiquid Liquid Extraction Equipment Laboratory

VIEW MORELiquid Liquid Extraction Equipment Laboratory