Liquid Liquid Extraction Equipment Laboratory

Configuration:desktop base edition, mobile standard edition, environmentally friendly high edition

Mixing volumn: 200ml, 300ml, 500ml, 1L, 2L, 3L or customized

Plate thickness:5mm,6mm,8mm,10mm

Material: PP,PPH,PVC,transparent PVC,PMMA,PTFE,PEEK,SUS,Ti

Production process: welding,bonding,bending,injection molding,integral forming

Optional function: temperature control device, pH adjustment device, water-bath jacket device, anti-overflow tank device,watch window device

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable mixer-settler stage amount, adjustable agitator speed, and adjustable phase interface height;Highly customizable

Application:rare earth extraction;nickel cobalt extraction;rubidium cesium extraction;salt lake brine extraction;nuclear extraction;isotope extraction;lithium battery recycling;vanadium battery recycling;copper electroplate recycling;biological wastewater recycling

- Product Description

Shaanxi Cuiyan: Your Trusted Liquid Liquid Extraction Equipment Laboratory Manufacturer & Supplier

Shaanxi Cuiyan Technology Co., Ltd, established in 2012, is a leading manufacturer and supplier of liquid liquid extraction equipment laboratory systems. With a team of 37 experts from top Chinese universities, we've delivered 10,000+ stages of extraction equipment to 300+ global clients. Our lab-scale systems combine automation, energy efficiency, and modular designs to meet diverse research needs while ensuring precision and durability.

Liquid Liquid Extraction Equipment Laboratory Description

Our liquid liquid extraction equipment laboratory systems are engineered for seamless phase separation, adjustable parameters, and compatibility with corrosive solvents. Ideal for R&D, quality control, and process optimization, these units are trusted in pharmaceuticals, environmental science, and more.

Specifications

| Specifications | Options |

|---|---|

| Configuration | Desktop Base Edition, Mobile Standard Edition, Eco-Friendly High Edition |

| Mixing Volume | 200mL, 300mL, 500mL, 1L, 2L, 3L (Customizable) |

| Plate Thickness | 5mm, 6mm, 8mm, 10mm |

| Material | PP, PPH, PVC, Transparent PVC, PMMA, PTFE, SUS, Ti |

| Production Process | Welding, Bonding, Bending, Injection Molding, Integral Forming |

| Optional Functions | Temperature Control, pH Adjustment, Anti-Overflow Tank, Watch Window |

Why Choose Our product?

- Precision & Efficiency: Achieve >95% extraction rates with optimized agitation and phase separation.

- Corrosion Resistance: SUS/Ti materials withstand acidic/alkaline environments.

- Customizable Workflows: Add sensors (pH, temperature) or integrate with PLC systems.

- Modular Design: Scale from benchtop to pilot plant with interchangeable modules.

- Energy-Saving: Reduce solvent consumption by 20% vs. traditional systems.

Material & Processing Methods

Choose from PP for cost-effective prototyping or PTFE/PMMA for high-purity applications. Our integral forming technique eliminates leakage risks, while laser-welded joints ensure structural integrity.

Key Functions

- Adjustable Parameters: Control agitator speed (50–500 RPM), phase interface height, and dwell time.

- Anti-Bubbling Design: Minimize cross-contamination with patented baffle structures.

- One-Step Filling/Emptying: Save 30% setup time with automated fluid handling.

How It Works

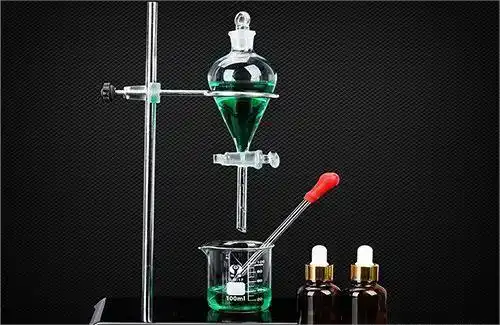

- Mixing Phase: Solvent and sample are agitated to transfer target compounds.

- Settling Phase: Immiscible phases separate naturally or via centrifugal force.

- Collection: Isolated phases are drained via precision valves for analysis.

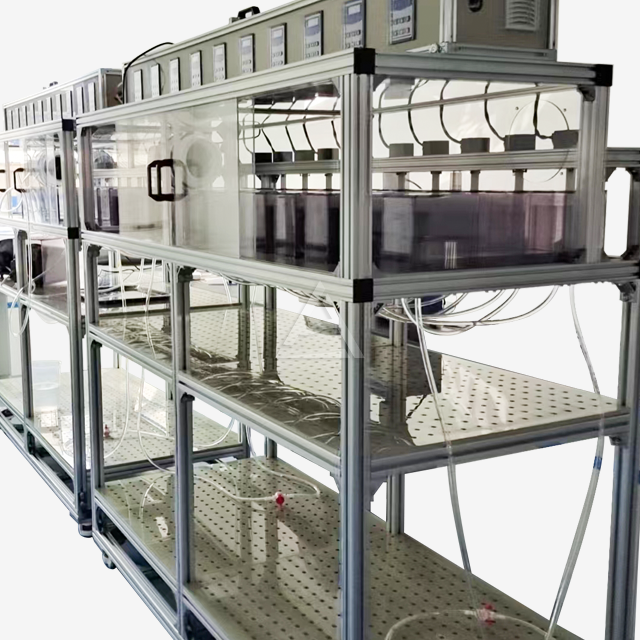

Physical Display

We’re showing a real liquid liquid extraction equipment laboratory here. The pictures give a clear understanding of its appearance. You can reach us anytime for further assistance.

User Guide

- Setup

The setup process kicks off with carefully mounting the unit on a stable surface, ensuring it is firmly secured to prevent any accidental movement during operation. Once in place, connect the tubing in a meticulous manner. Check for proper alignment and tight fittings to avoid leaks that could disrupt the system's performance. If the unit is equipped with sensors, calibration is a crucial next step. Use reference standards and follow the manufacturer's guidelines to accurately calibrate these sensors. This ensures they provide precise data, whether measuring temperature, pressure, or other variables, setting the stage for reliable operation. - Operation

When it's time to operate, start by loading the samples into the designated chambers, taking care to handle them with precision and avoid any contamination. Next, access the touchscreen interface, which is designed for user - friendliness. Navigate through the intuitive menus to set parameters such as processing time, speed, or intensity based on the requirements of the samples. Once all parameters are set, simply press the start button to initiate the cycle. Throughout the process, the touchscreen can be used to monitor the progress and make any necessary adjustments. - Maintenance

To keep the unit in optimal condition, maintenance is key. After each use, rinse it thoroughly with deionized water. Deionized water is ideal as it lacks impurities that could leave residues or cause corrosion. Start from the sample chambers and work your way through the tubing, ensuring all parts are cleaned. Additionally, conduct a monthly inspection of the seals. Look for signs of wear, such as cracks, swelling, or reduced elasticity. If any issues are detected, replace the seals promptly to maintain the integrity of the unit and prevent leaks that could affect performance and safety.

Application Areas

- Pharmaceuticals: Purify APIs or extract natural compounds.

- Environmental Testing: Detect heavy metals in wastewater.

- Battery Recycling: Recover lithium, cobalt, or vanadium.

- Academic Research: Teach separation techniques with visible phase boundaries.

Packaging & Transportation

Units are shock-proof crated with foam inserts and shipped globally via DHL/FedEx.

After-Sales Service

12-month warranty, lifetime technical support, and <48hr response time for spare parts.

Qualification Certification

ISO 9001, CE, and REACH compliance ensures safety and environmental standards.

FAQs

Q: Can I customize the mixing volume for small-scale experiments?

A: Yes! We offer volumes from 200mL to 3L, or tailor-made designs.

Q: How do you prevent solvent leakage?

A: Double-layered seals and precision-machined joints ensure zero leakage.

Q: Is the equipment compatible with high-temperature solvents?

A: Absolutely. SUS316L or PTFE materials withstand up to 200°C.

Q: What's the lead time for an Eco-Friendly High Edition unit?

A: Standard units ship in 2–3 weeks; customized orders take 4–6 weeks.

Q: Do you provide installation training?

A: Yes – free remote training via Zoom or on-site support (optional).

Contact Us

Elevate your lab's capabilities with a liquid liquid extraction equipment laboratory system built for accuracy and adaptability. Email wangzhijun@cuiyan-tec.com to discuss your project!