Liquid Liquid Extraction Process Equipment

- Product Description

Shaanxi Cuiyan: Your Trusted Liquid Liquid Extraction Process Equipment Manufacturer & Supplier

Shaanxi Cuiyan Technology Co., Ltd, established in 2012, is a trusted manufacturer and supplier of liquid liquid extraction process equipment, specializing in lab, pilot, and industrial-scale solutions. With 37+ experts, 9 patented technologies, and 300+ global clients, we deliver corrosion-resistant, customizable systems that optimize extraction efficiency while reducing operational costs.Our lab-scale mixer-settler units are engineered for precise phase separation in small-volume applications, ideal for R&D, process optimization, and pilot testing.

Liquid Liquid Extraction Process Equipment Specifications

| Specifications | Details |

|---|---|

| Configuration | Desktop Base Edition, Mobile Standard Edition, Eco-Friendly High Edition |

| Mixing Volume | 200ml, 300ml, 500ml, 1L, 2L, 3L (Customizable) |

| Plate Thickness | 5mm, 6mm, 8mm, 10mm |

| Material Options | PP, PPH, PVC, Transparent PVC, PMMA, PTFE, PEEK, SUS, Ti |

| Production Process | Welding, Bonding, Bending, Injection Molding, Integral Forming |

| Optional Functions | Temperature Control, pH Adjustment, Anti-Overflow Tank, Water-Bath Jacket |

Why Choose Our product?

- Proven Expertise: Over a decade of refining extraction technology with 10,000+ stages sold globally.

- Smart Customization: Integrate sensors (pH, temperature) or design industry-specific tanks.

- Energy Efficiency: Modular structures reduce solvent/energy waste by 15–20%.

- Zero Leakage: Anti-bubbling design and reinforced seals ensure safe operation.

Material & Processing Excellence

Choose corrosion-resistant materials like PTFE for acidic environments or titanium for high-temperature processes. Our bonding and welding techniques exceed ISO 9001 standards, guaranteeing longevity even under aggressive chemical conditions.

Key Functions

- Adjustable agitator speed (50–500 RPM) for optimal mixing.

- Phase interface control via precision weirs.

- Real-time monitoring with integrated sensors (optional).

How It Works

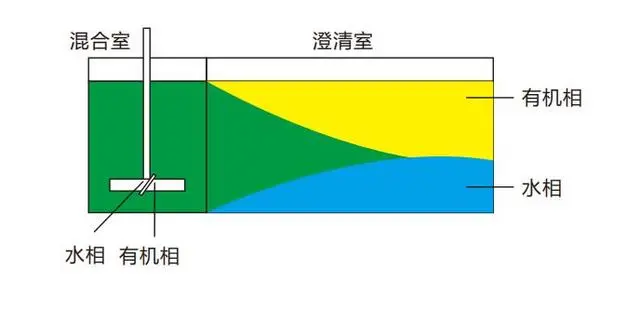

The liquid liquid extraction process equipment operates in three stages:

- Mixing: Two immiscible phases (e.g., organic/aqueous) are agitated to transfer solutes.

- Settling: Phases separate naturally in the clarification zone.

- Collection: Purified streams are discharged through dedicated outlets.

Physical Display

A real product demonstration is shown here. You can clearly see how the product looks. Feel free to get in touch for more information.

User Guide

- Setup: Mount the unit on a stable surface; connect utilities (power, coolant).

- Calibration: Set agitator speed and phase height via the control panel.

- Operation: Monitor parameters through the digital interface or optional sensors.

Applications

- Rare earth, nickel - cobalt, and rubidium - cesium extraction

In the pursuit of valuable elements, extraction processes for rare earths, nickel - cobalt, and rubidium - cesium are highly specialized. Rare earths, essential for electronics and clean energy technologies, are extracted from ores through chemical leaching and solvent extraction methods. Nickel - cobalt, crucial for battery manufacturing, are recovered from sulfide or laterite ores using hydrometallurgical and pyrometallurgical techniques. Rubidium - cesium, with applications in atomic clocks and medical imaging, are extracted from their respective minerals via ion - exchange and fractional crystallization, ensuring a sustainable supply of these vital elements. - Lithium/vanadium battery recycling, nuclear waste treatment

The recycling of lithium/vanadium batteries is a growing necessity in the era of electric vehicles and energy storage. Spent batteries are first dismantled, and then chemical processes are used to recover lithium and vanadium, reducing the need for virgin mining. In nuclear waste treatment, advanced techniques such as vitrification are employed. Radioactive waste is mixed with glass - forming materials and heated to high temperatures, solidifying the waste into a stable glass matrix. This immobilizes the radioactive substances, minimizing environmental risks and ensuring long - term safety. - Biofuel purification, pharmaceutical intermediate separation

Biofuel purification is vital to enhance the quality and efficiency of biofuels like ethanol and biodiesel. Impurities such as water, acids, and unreacted feedstocks are removed through distillation, filtration, and adsorption processes. This results in a cleaner - burning fuel with better performance. In pharmaceutical intermediate separation, high - precision techniques such as chromatography and crystallization are used. These methods separate complex mixtures of chemical compounds, ensuring that pharmaceutical intermediates are of high purity, which is crucial for the production of safe and effective drugs.

Compact & Secure Delivery

All units are disassembled into modular parts, wrapped in anti-static film, and shipped in shock-proof crates. Delivery time: 7–15 days.

Reliable Support

Enjoy 24/7 technical support, 2-year warranties, and emergency spare parts delivery.

Certified Quality

Compliant with CE, ISO 9001, and industrial safety regulations.

FAQs

Q1: Can you customize materials for highly corrosive solvents?

Yes! We offer SUS 316L, titanium, and PTFE-lined options.

Q2: Is automation compatible with PLC systems?

Our equipment supports Siemens/Allen-Bradley PLC integration.

Q3: What's the lead time for a 3L customized unit?

Typically 3–4 weeks.

Q4: Do you provide on-site installation?

Global technicians are available for complex setups.

Q5: How to optimize extraction efficiency?

Adjust mixer speed and residence time based on solvent viscosity.

Contact Us

Email wangzhijun@cuiyan-tec.com to request a quote, technical specs, or a free consultation of liquid liquid extraction process equipment.

VIEW MORELiquid Liquid Extraction System

VIEW MORELiquid Liquid Extraction System VIEW MOREMixer Settler Equipment

VIEW MOREMixer Settler Equipment VIEW MOREMixer Settler For Liquid Liquid Extraction

VIEW MOREMixer Settler For Liquid Liquid Extraction VIEW MOREExperimental Used Mixer Settler

VIEW MOREExperimental Used Mixer Settler VIEW MOREEnvironmentally Friendly Mixer Settler

VIEW MOREEnvironmentally Friendly Mixer Settler VIEW MOREPilot Scale Mixer Settler

VIEW MOREPilot Scale Mixer Settler VIEW MOREPilot Extraction System

VIEW MOREPilot Extraction System VIEW MOREMixer Settler Systems

VIEW MOREMixer Settler Systems