Experimental Used Mixer Settler

Configuration:desktop base edition, mobile standard edition, environmentally friendly high edition

Mixing volumn: 200ml, 300ml, 500ml, 1L, 2L, 3L or customized

Plate thickness:5mm,6mm,8mm,10mm

Material: PP,PPH,PVC,transparent PVC,PMMA,PTFE,PEEK,SUS,Ti

Production process: welding,bonding,bending,injection molding,integral forming

Optional function: temperature control device, pH adjustment device, water-bath jacket device, anti-overflow tank device,watch window device

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable mixer-settler stage amount, adjustable agitator speed, and adjustable phase interface height;Highly customizable

Application:rare earth extraction;nickel cobalt extraction;rubidium cesium extraction;salt lake brine extraction;nuclear extraction;isotope extraction;lithium battery recycling;vanadium battery recycling;copper electroplate recycling;biological wastewater recycling

- Product Description

Shaanxi Cuiyan: Your Trusted Experimental Used Mixer Settler Manufacturer & Supplier

Shaanxi Cuiyan Technology Co., Ltd., established in 2012, specializes in designing and producing experimental used mixer settlers for labs and industrial R&D. With 37+ experts and 10,000+ stages sold globally, our equipment combines automation, modularity, and patented innovations to deliver unmatched extraction efficiency.

Experimental Used Mixer Settler Description

Our Experimental Used Mixer Settler is engineered for precision, adaptability, and durability. Ideal for rare metal extraction, wastewater recycling, and chemical research, it supports seamless integration with sensors and automation.

Specifications

| Specifications | Details |

|---|---|

| Configuration | Desktop Base, Mobile Standard, Eco-Friendly High Edition |

| Mixing Volume | 200mL–3L (Customizable) |

| Plate Thickness | 5mm–10mm |

| Material Options | PP, PPH, PVC, Transparent PVC, PMMA, PTFE, PEEK, SUS, Ti |

| Production Process | Welding, Bonding, Bending, Injection Molding, Integral Forming |

| Optional Functions | Temperature Control, pH Adjustment, Anti-Overflow Tank, Water-Bath Jacket |

Why Choose Our product?

- Customization First: Tailor mixing stages, agitator speed, and tank design to your process.

- Energy-Saving Design: Modular structure reduces energy use by 30% vs. traditional models.

- Zero Leakage Guarantee: Anti-bubbling and one-step tank filling/emptying ensure safety.

- Patented Tech: 9+ national patents validate our extraction efficiency and process innovation.

Material & Processing Excellence

Choose from 10+ corrosion-resistant materials, including PTFE for acidic environments or titanium for nuclear applications. Our advanced bonding and injection molding ensure leak-proof joints and extended equipment life.

How It Works

- Mixing Phase: Agitators blend liquids for optimal solvent contact.

- Settling Phase: Gravity separates phases with precision interface control.

- Automation: Sensors monitor pH, temperature, and liquid levels in real time.

Key Applications

- Rare Earth & Battery Recycling: Efficient lithium, cobalt, and nickel recovery.

- Nuclear & Isotope Extraction: Radiation-resistant titanium models available.

- Wastewater Treatment: Remove heavy metals with >95% efficiency.

- Pharmaceutical Purification: FDA-compliant designs for drug R&D.

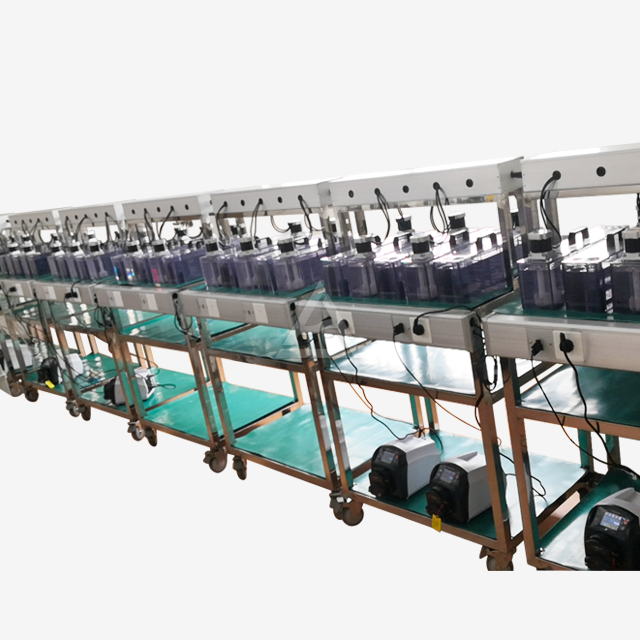

Physical Display

Here you'll find physical Experimental Used Mixer Settler displays. The photos give a clear view of the design and function. We're ready to support you with more information anytime.

User Guide

- Setup

During setup, start by carefully connecting all the sensors to their designated ports. Ensure that the connections are secure to prevent any signal disruptions. Then, turn to the control panel, which is designed to be user - friendly. Navigate through the menu options to configure the agitator speed according to the requirements of your specific process. Whether you're dealing with a gentle mixing task or a more vigorous one, the control panel allows for precise speed adjustments. Double - check all settings and connections before proceeding to ensure a smooth start to the operation. - Calibration

Calibration involves an important step of adjusting the phase interface height. Locate the manual override feature on the system, which gives you direct control over this crucial parameter. In processes where two or more immiscible phases are present, such as in liquid - liquid extraction, the correct phase interface height is essential for efficient separation. Use the manual override to make incremental adjustments, observing the changes in the separation process. This hands - on calibration method allows for fine - tuning to achieve optimal performance. - Maintenance

Maintenance is key to the long - term functionality of the equipment. After each use, thoroughly clean the tanks to remove any residue from the substances processed. Use appropriate cleaning agents and tools to ensure a complete clean. Additionally, conduct a monthly inspection of the seals. Check for signs of wear, such as cracks, leaks, or swelling. If any issues are detected, promptly replace the seals. Regular maintenance not only extends the lifespan of the equipment but also helps maintain the integrity of the processes it supports.

Packaging & Transportation

Crush-proof packaging with shock-absorbent foam ensures safe global delivery.

After-Sales Service

24/7 technical support and a 2-year warranty on all components.

Qualification Certification

ISO 9001, CE, and nuclear safety certifications available upon request.

FAQ

Q: Can I retrofit existing equipment with your sensors?

A: Yes! Our modular design supports retrofitting pH, temperature, or level sensors.

Q: Do you comply with ASTM standards?

A: All equipment meets ISO, ASTM, and nuclear safety certifications.

Q: What's the lead time for customized orders?

A: 4–6 weeks for most orders; urgent requests get priority.

Q: Which material suits high-temperature extraction?

A: SUS 316 or titanium for temperatures up to 200°C.

Q: Do you offer onsite training?

A: Free remote training included; onsite support available at cost.

Contact Us

Ready to optimize your extraction process? Email wangzhijun@cuiyan-tec.com for a free consultation or custom quote of Experimental Used Mixer Settler!