Counter Current Extractor

Configuration:desktop base edition, mobile standard edition, environmentally friendly high edition

Mixing volumn: 200ml, 300ml, 500ml, 1L, 2L, 3L or customized

Plate thickness:5mm,6mm,8mm,10mm

Material: PP,PPH,PVC,transparent PVC,PMMA,PTFE,PEEK,SUS,Ti

Production process: welding,bonding,bending,injection molding,integral forming

Optional function: temperature control device, pH adjustment device, water-bath jacket device, anti-overflow tank device,watch window device

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable mixer-settler stage amount, adjustable agitator speed, and adjustable phase interface height;Highly customizable

Application:rare earth extraction;nickel cobalt extraction;rubidium cesium extraction;salt lake brine extraction;nuclear extraction;isotope extraction;lithium battery recycling;vanadium battery recycling;copper electroplate recycling;biological wastewater recycling

- Product Description

Shaanxi Cuiyan: Your Trusted Counter Current Extractor Manufacturer & Supplier

Shaanxi Cuiyan Technology Co., Ltd. – A trusted prouct manufacturer & supplier since 2012, we specialize in high-performance extraction systems. With 37+ experts and 9 patented advantages, including automated controls, energy-saving modular designs, and industry-leading customization, our equipment serves 300+ global clients with 10,000+ stages delivered.Our lab scale mixer settler counter current extractor combines precision engineering with flexible configurations for research and small-scale production.

Counter Current Extractor Specifications

| Specifications | Details |

|---|---|

| Configuration | Desktop Base, Mobile Standard, Eco-Friendly High Edition |

| Mixing Volume | 200mL – 3L (Customizable) |

| Plate Thickness | 5mm – 10mm |

| Material Options | PP, PPH, PVC, Transparent PVC, PMMA, PTFE, PEEK, SUS, Ti |

| Production Process | Welding, Bonding, Bending, Injection Molding, Integral Forming |

| Optional Functions | Temperature Control, pH Adjustment, Anti-Overflow Tank, Watch Window |

Why Choose Our product?

- ✅ Tailored Solutions: Customize stage amounts, agitator speeds, and materials (e.g., FDA-compliant PTFE for pharmaceuticals).

- ✅ Energy Efficiency: Modular design reduces operational costs by 20%+ for green chemistry applications.

- ✅ Zero Leakage: Anti-bubbling and one-step tank emptying ensure safe, clean operations.

- ✅ Smart Integration: Add sensors (pH, temperature) or IoT modules for real-time monitoring.

Materials & Processing

- PP/PPH: Ideal for acidic environments (e.g., lithium battery recycling).

- SUS/Ti: Withstand high-temperature nuclear extraction processes.

- Transparent PVC/PMMA: Visual monitoring for R&D labs.

Precision Manufacturing: Laser-cut plates and robotic welding ensure <0.1mm tolerance.

Key Functions

- Adjustable phase interface height for optimal separation.

- Water-bath jackets maintain stable temperatures (±1°C).

- Anti-overflow tanks prevent cross-contamination.

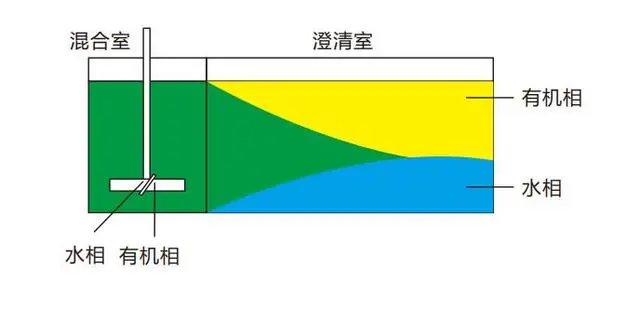

How It Works

- Mixing: Two immiscible phases blend in the mixer for efficient mass transfer.

- Settling: Phases separate in the clarifier based on density.

- Counter-Current Flow: Continuous extraction maximizes yield with minimal solvent use.

Applications

- Rare Earth & Battery Recycling: Extract lithium, cobalt, nickel with >95% efficiency.

- Pharmaceuticals: Purify APIs using GMP-grade materials.

- Environmental Protection: Recover heavy metals from wastewater.

Packaging & Transportation

Our commitment to safeguarding your products during transit is unwavering. For packaging, we use shock - proof crating materials that are designed to absorb and dissipate any impacts. This ensures that delicate components within the counter current extractor remain intact. Complementing this, our climate - controlled logistics system maintains optimal temperature and humidity levels. Whether the shipment is crossing hot deserts or cold mountainous regions, your product is protected from environmental factors that could potentially damage it.

After - Sales Service

We understand the importance of continuous support even after the sale. Our 24/7 technical support team is always on standby. Comprising highly trained professionals, they can be reached via phone, email, or live chat at any time. In case of any issues, they provide prompt troubleshooting and guidance. Additionally, our 2 - year warranty offers peace of mind. If there are any manufacturing defects within this period, we will repair or replace the product at no extra cost to you.

Certifications

Our compliance with ISO 9001, CE, and REACH certifications speaks volumes about our quality and safety standards. ISO 9001 validates our comprehensive quality management system, ensuring every aspect of production is top - notch. CE compliance indicates that our products meet European health, safety, and environmental protection requirements. REACH compliance shows our dedication to managing chemical substances responsibly, making our products safe for both users and the environment.

FAQs

Q: Can you customize extractors for high-pressure processes?

A: Yes! We offer PEEK/SUS materials rated up to 150°C and 10 bar.

Q: Do your systems comply with FDA standards?

A: Absolutely. We provide full documentation for pharmaceutical audits.

Q: How long is the lead time?

A: Standard units ship in 4 weeks; custom designs take 6–8 weeks.

Q: Can I upgrade my existing system?

A: Yes – modular designs allow easy expansion.

Q: Do you offer on-site training?

A: Free video guides included; onsite training available upon request.

Contact Us

Need a counter current extractor that adapts to your workflow? Email wangzhijun@cuiyan-tec.com for a quote or technical consultation.