Battery Mixer Settler

Configuration:desktop base edition, mobile standard edition, environmentally friendly high edition

Mixing volumn: 200ml, 300ml, 500ml, 1L, 2L, 3L or customized

Plate thickness:5mm,6mm,8mm,10mm

Material: PP,PPH,PVC,transparent PVC,PMMA,PTFE,PEEK,SUS,Ti

Production process: welding,bonding,bending,injection molding,integral forming

Optional function: temperature control device, pH adjustment device, water-bath jacket device, anti-overflow tank device,watch window device

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable mixer-settler stage amount, adjustable agitator speed, and adjustable phase interface height;Highly customizable

Application:rare earth extraction;nickel cobalt extraction;rubidium cesium extraction;salt lake brine extraction;nuclear extraction;isotope extraction;lithium battery recycling;vanadium battery recycling;copper electroplate recycling;biological wastewater recycling

- Product Description

Shaanxi Cuiyan: Your Trusted Battery Mixer Settler Manufacturer & Supplier

Shaanxi Cuiyan Technology Co., Ltd. is a trusted battery mixer settler manufacturer & supplier with over a decade of expertise in designing lab-scale extraction systems. Our equipment integrates automation, energy-saving modular designs, and patented anti-bubbling technology to deliver precise, corrosion-resistant solutions for industries like lithium battery recycling and rare earth extraction.

Battery Mixer Settler Description

Our battery mixer settler is engineered to streamline liquid-liquid extraction processes with unmatched efficiency. Designed for labs and pilot plants, it supports scalable customization, enabling seamless integration into diverse production environments.

Specifications

| Specifications | Details |

|---|---|

| Configuration | Desktop Base Edition, Mobile Standard Edition, Environmentally Friendly High Edition |

| Mixing Volume | 200mL to 3L (Customizable) |

| Plate Thickness | 5mm, 6mm, 8mm, 10mm |

| Material Options | PP, PPH, PVC, Transparent PVC, PMMA, PTFE, SUS, Ti |

| Production Process | Welding, Bonding, Injection Molding, Integral Forming |

| Optional Functions | Temperature Control, pH Adjustment, Anti-Overflow Tank, Watch Window |

Why Choose Our product?

- Precision & Flexibility: Adjustable agitator speed and phase interface height ensure perfect separation for varied chemical viscosities.

- Durability: High-corrosion-resistant materials (e.g., PTFE, SUS316) extend equipment lifespan even in harsh environments.

- Smart Automation: IoT-ready sensors (temperature, pH, liquid level) enable real-time process monitoring.

- Scalable Design: Modular units allow rapid installation or expansion to meet growing production demands.

Material & Processing Method

- Materials: PP (lightweight), PVC (chemical resistance), SUS316 (high-temperature stability), PTFE (ultra-corrosion resistance).

- Fabrication: Laser-cut components with robotic welding ensure leak-proof seams.

How It Works

The battery mixer settler operates in two stages:

- Mixing: Agitators blend immiscible liquids to transfer target ions.

- Settling: Gravity separates phases in clarified chambers, ensuring 99%+ extraction efficiency.

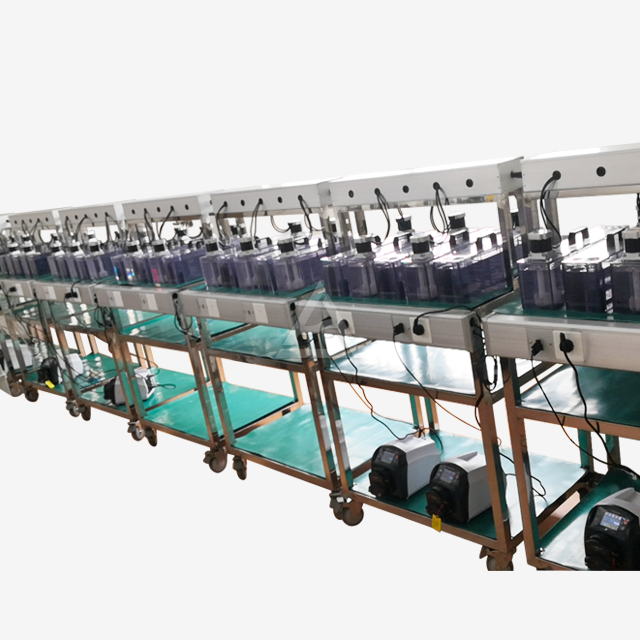

Physical Display

These real product displays give you a clear look at our machinery. Browse the images to better understand the structure.

User Guide

- Setup: Assemble modules per flow diagram (included).

- Calibration: Input parameters via touchscreen (optional).

- Operation: Monitor via dashboard; adjust speed/pH as needed.

Application Areas

- Battery Recycling: Lithium - ion, vanadium, and copper electroplating waste recovery

Battery recycling is crucial for resource conservation and environmental protection. In lithium - ion battery recycling, spent batteries are first dismantled to separate components. Chemical leaching techniques are then employed to extract lithium, cobalt, and other valuable metals. Vanadium, often used in vanadium redox flow batteries, is recovered from spent units through similar processes. Regarding copper electroplating waste, it contains copper that can be reclaimed. Precipitation and electrolysis methods are utilized to purify and retrieve the copper, reducing the need for virgin material extraction and minimizing waste disposal. - Rare Metals: Rubidium, cesium, and nickel - cobalt extraction

The extraction of rubidium, cesium, and nickel - cobalt involves intricate procedures. Rubidium and cesium, with unique properties used in atomic clocks and medical imaging, are obtained from minerals or brines. Techniques like ion - exchange and solvent extraction are applied to isolate these rare metals. Nickel - cobalt, essential for battery anodes and superalloys, are extracted from ores. Crushing, grinding, and froth flotation are initial steps, followed by smelting and refining processes to obtain high - purity nickel - cobalt alloys, meeting the demands of various high - tech industries. - Environmental: Biological wastewater treatment, salt lake brine processing

Biological wastewater treatment is a sustainable solution for purifying wastewater. Microorganisms, such as bacteria and fungi, are used to break down organic pollutants. In aerobic treatment, oxygen - consuming microbes decompose contaminants, while anaerobic treatment relies on oxygen - free conditions. This process reduces the environmental impact of wastewater discharge. Salt lake brine processing, on the other hand, focuses on extracting valuable minerals like lithium, potassium, and magnesium. Evaporation, precipitation, and ion - exchange methods are used to separate and purify these minerals, turning salt lake resources into useful products.

Packaging & Transportation

Crate-protected with shock-absorbent materials; global shipping via air/sea.

After-Sales Service

24/7 technical support with on-site training and spare parts supply.

Qualification Certification

ISO 9001, CE, and RoHS compliant.

FAQs

Q: Can this handle high-viscosity solutions?

A: Yes—custom agitator designs ensure optimal mixing for viscous fluids.

Q: Is remote monitoring possible?

A: Optional IoT integration allows cloud-based data tracking.

Q: What's the lead time for a customized order?

A: 4–6 weeks, depending on design complexity.

Q: How energy-efficient is the system?

A: Energy consumption is 30% lower than conventional models.

Q: Do you provide installation support?

A: Yes—our engineers assist with setup worldwide.

Contact Us

Elevate your extraction process with a battery mixer settler built for precision. Email wangzhijun@cuiyan-tec.com for a quote or technical consultation.