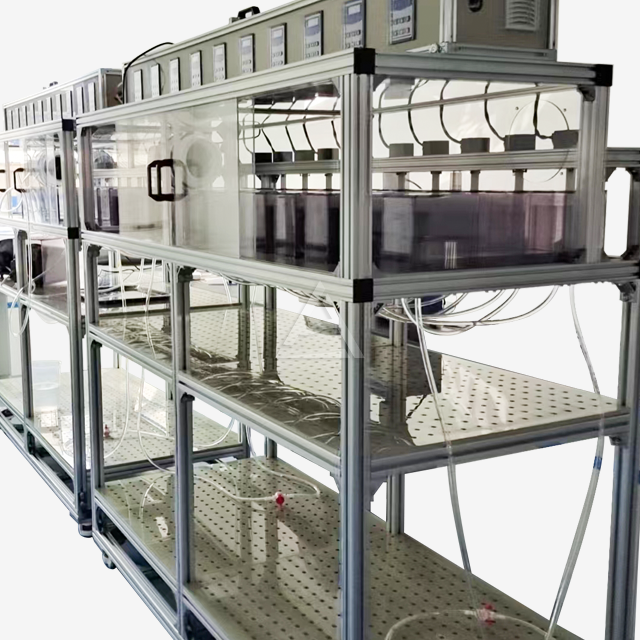

Biological Wastewater Industry Mixer Settler

Cooperation solution: labor+material contracting,labor-ony contracting

Mixing volumn: 100L,200L,300L,500L,800L,1000L or customized

Plate thickness:12mm,15mm,20mm,25mm,30mm

Material: PP,PPH,PVC,transparent PVC

Production process: welding

Optional function: temperature control device,pH adjustment device,anti-overflow tank device

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable agitator speed,adjustable phase interface height

Application: rare earth extraction;nickel cobalt extraction;rubidium cesium extraction;salt lake brine extraction;nuclear extraction;lithium battery recycling;vanadium battery recycling;copper electroplate recycling;biological wastewater recycling

- Product Description

Shaanxi Cuiyan: Your Trusted Biological Wastewater Industry Mixer Settler Manufacturer & Supplier

Shaanxi Cuiyan Technology Co., Ltd., established in 2012, is a leading biological wastewater industry mixer settler manufacturer specializing in corrosion-resistant, modular extraction systems. With 300+ global clients and 10,000+ stages sold, our equipment integrates automated controls, energy-saving designs, and patented anti-bubbling technology to deliver precise separation for industries like pharmaceuticals, mining, and lithium battery recycling.

Biological Wastewater Industry Mixer Settler Description

Our biological wastewater industry mixer settler optimizes heavy metal recovery and organic pollutant removal through adjustable agitation and phase separation. Designed for scalability, it supports seamless integration into existing wastewater treatment workflows while meeting strict environmental compliance standards.

Specifications

| Parameter | Options |

|---|---|

| Mixing Volume | 100L, 200L, 300L, 500L, 800L, 1000L (Customizable) |

| Plate Thickness | 12mm, 15mm, 20mm, 25mm, 30mm |

| Material | PP, PPH, PVC, Transparent PVC |

| Production Process | Welding |

| Optional Functions | Temperature Control, pH Adjustment, Anti-Overflow Tank |

Why Choose Our Mixer Settler?

- 98% Extraction Efficiency: Achieve perfect phase separation for metals like nickel, cobalt, and copper.

- Leak-Proof Design: Robotic welding ensures zero fluid loss in corrosive environments.

- Rapid Deployment: Modular units install in 72 hours, minimizing downtime during plant upgrades.

- Smart Sensors: Integrated pH, temperature, and liquid-level monitoring for real-time adjustments.

Material & Processing Method

Constructed from PPH (Polypropylene Homopolymer), our mixer settlers withstand pH extremes (1–14) and temperatures up to 90°C. CNC-machined components and automated welding guarantee <0.01mm assembly tolerances for long-term durability.

How It Works

- Mixing Phase: Adjustable impellers (50–300 RPM) create optimal turbulence for chemical reagent blending.

- Settling Phase: Sloped clarifier plates accelerate sludge settling, achieving 99.9% clarified effluent output.

- Automation: PLC systems auto-adjust interface levels and trigger emergency shutoffs during overflow risks.

Applications

- Heavy Metal Recovery (Cu, Zn, Cd)

In heavy metal recovery processes targeting copper (Cu), zinc (Zn), and cadmium (Cd), wastewater or industrial residues are the primary sources. Initial treatment often involves filtration to remove solid debris. Then, chemical precipitation methods are applied, where specific chemicals are added to form insoluble metal compounds. For example, adding sodium hydroxide can precipitate metal hydroxides. After precipitation, the solids are separated through sedimentation or filtration. Electrochemical methods may also be used for further purification and extraction. Recovering these metals not only reduces environmental pollution but also allows for their reuse in various industries, like copper in electronics and zinc in galvanization. - Pharmaceutical Wastewater (COD Reduction)

Pharmaceutical wastewater contains a high concentration of Chemical Oxygen Demand (COD) substances, which pose a significant environmental threat. Treatment typically begins with biological processes, such as activated sludge systems. Microorganisms in the sludge break down organic compounds, reducing the COD. Advanced oxidation processes may be employed as a supplementary step. These use strong oxidants like ozone or hydrogen peroxide to further degrade complex organic molecules that are difficult to break down biologically. Filtration and disinfection steps are also included to ensure the treated water meets discharge standards, preventing contamination of water bodies and protecting public health. - Lithium Battery Recycling (Li, Co Extraction)

Lithium battery recycling focuses on extracting valuable lithium (Li) and cobalt (Co). Spent batteries are first dismantled to separate components. The battery materials are then subjected to chemical leaching, usually with acids, to dissolve Li and Co. After leaching, techniques like solvent extraction are used to selectively isolate these metals from the leachate. Precipitation methods are further applied to purify and obtain concentrated forms of Li and Co. The recovered metals can be directly reused in new battery manufacturing, reducing the reliance on virgin mining and minimizing the environmental impact associated with battery disposal. - Food & Beverage Effluent Treatment

Food and beverage effluent contains a variety of contaminants, including organic matter, suspended solids, and nutrients. Treatment starts with physical processes such as screening to remove large particles and sedimentation to settle heavier solids. Biological treatment follows, where aerobic or anaerobic microorganisms break down the organic matter. In aerobic treatment, bacteria use oxygen to decompose contaminants, while anaerobic treatment occurs in the absence of oxygen. Nutrient removal processes, like nitrification and denitrification for nitrogen and chemical precipitation for phosphorus, are also crucial. Wastewater treated by the biological wastewater industry mixer settler must meet regulatory standards before it can be discharged to prevent water source pollution and protect aquatic ecosystems.

User Guide

- Step 1: Confirm wastewater parameters (pH, contaminant concentration).

- Step 2: Select tank size and material based on chemical compatibility.

- Step 3: Integrate optional sensors for automated process control.

Packaging

Wooden crates with moisture-proof coating;

After-Sales

2-year warranty + lifetime support

FAQ

Q: Can this handle acidic mining wastewater?

A: Yes—our PPH material resists sulfuric acid (up to 60% concentration).

Q: Is CE certification available?

A: We provide CE, ISO 9001, and custom certifications for EU/NA markets.

Q: What's the lead time for 500L units?

A: 4–6 weeks with expedited shipping options.

Q: Do you offer onsite installation support?

A: Global technical teams assist with commissioning and staff training.

Q: How to reduce energy consumption?

A: Variable frequency drives (VFDs) cut power use by 35% during low-load operations.

Contact Us

Whether you're retrofitting a municipal plant or scaling battery recycling operations, our biological wastewater industry mixer settler delivers unmatched reliability. Contact us at wangzhijun@cuiyan-tec.com for a free process audit and tailored quotation.