Laboratory Mixer Settlers

Configuration:desktop base edition, mobile standard edition, environmentally friendly high edition

Mixing volumn: 200ml, 300ml, 500ml, 1L, 2L, 3L or customized

Plate thickness:5mm,6mm,8mm,10mm

Material: PP,PPH,PVC,transparent PVC,PMMA,PTFE,PEEK,SUS,Ti

Production process: welding,bonding,bending,injection molding,integral forming

Optional function: temperature control device, pH adjustment device, water-bath jacket device, anti-overflow tank device,watch window device

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable mixer-settler stage amount, adjustable agitator speed, and adjustable phase interface height;Highly customizable

Application:rare earth extraction;nickel cobalt extraction;rubidium cesium extraction;salt lake brine extraction;nuclear extraction;isotope extraction;lithium battery recycling;vanadium battery recycling;copper electroplate recycling;biological wastewater recycling

- Product Description

Shaanxi Cuiyan: Your Trusted Laboratory Mixer Settlers Manufacturer & Supplier

Shaanxi Cuiyan Technology Co., Ltd, established in 2012, specializes in lab-to-industrial extraction equipment. With 300+ global clients and 10,000+ stages delivered, our laboratory mixer settlers combine cutting-edge automation, modular design, and 9 patented advantages for corrosion resistance, scalability, and process precision.

Laboratory Mixer Settlers Description

Our product are engineered for small-scale extraction, separation, and purification tasks. Designed to replace manual methods, they ensure seamless transition from lab experiments to industrial production.

Specifications

| Specifications | Details |

|---|---|

| Configuration | Desktop Base, Mobile Standard, Eco-Friendly High Edition |

| Mixing Volume | 200mL – 3L (Customizable) |

| Plate Thickness | 5mm – 10mm |

| Material Options | PP, PPH, PVC, PMMA, SUS, Ti & More |

| Processing Methods | Welding, Injection Molding, Integral Forming |

| Optional Functions | Temperature Control, pH Adjustment, Anti-Overflow Tank, Watch Window |

Why Choose Our Laboratory Mixer Settlers?

- Automation Ready: Integrate with PLC/DCS systems for real-time monitoring.

- Energy-Saving Design: Reduce power consumption by 20% vs. traditional models.

- Bubble-Free Operation: Patented tank-filling tech ensures stable phase separation.

- Customizable: Add sensors (pH, temperature) or tailor materials for aggressive chemicals.

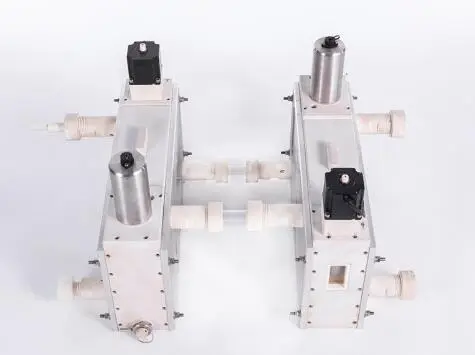

Material & Processing Methods

- Corrosion-Resistant Materials: SUS316L for acidic environments, PP for cost-effective solvent handling.

- Precision Manufacturing: Laser-cut welds and CNC-machined parts guarantee leak-proof performance.

Key Functions

- Adjust agitator speed (50–500 RPM) and phase interface height.

- Optional water-jacket heating (up to 80°C) for temperature-sensitive extractions.

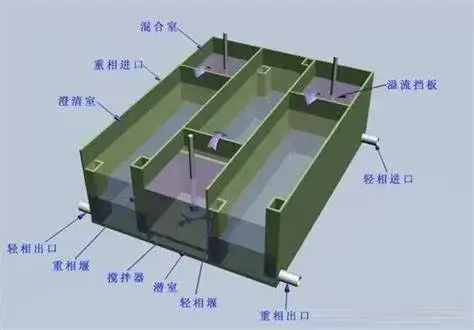

How It Works

- Mixing Stage: Agitators create optimal turbulence for solute transfer.

- Settling Stage: Gravity-driven separation in clarified zones.

- Continuous Flow: Modular stages enable multi-step processes in compact setups.

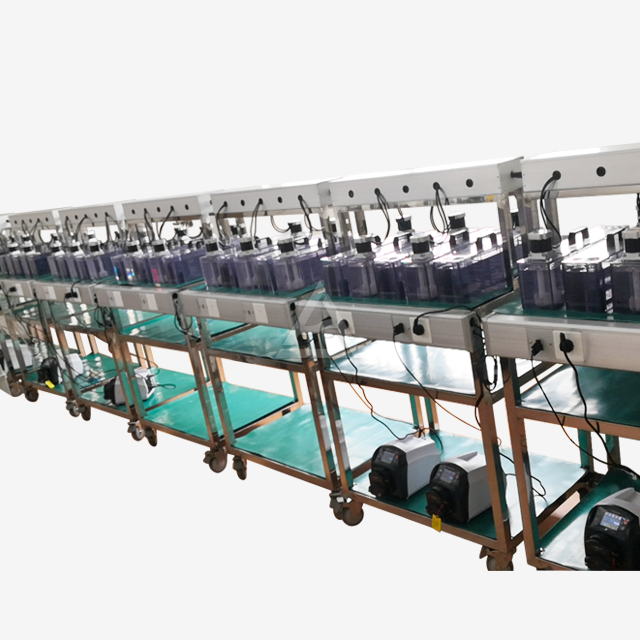

Physical Display

Our top-performing laboratory mixer settlers are on display. Browse the detailed pictures to see their real-world functionality.

User Guide

- Setup: Mount on benchtop, connect power, calibrate sensors.

- Operation: Load feed, set parameters via touchscreen, collect data via USB/Bluetooth.

- Maintenance: Clean with mild detergents; annual seal inspection recommended.

Applications

- Rare Earth & Battery Recycling: Lithium, cobalt, nickel recovery

In the realm of rare earth and battery recycling, the recovery of lithium, cobalt, and nickel is of utmost importance. With the growing demand for batteries in electric vehicles and portable electronics, recycling these metals becomes crucial. Our process starts with the collection and dismantling of spent batteries. Chemical leaching techniques are then employed to dissolve lithium, cobalt, and nickel from the battery components. Through a series of separation and purification steps, such as solvent extraction and precipitation, we can obtain high - purity versions of these metals. This not only reduces the need for virgin mining but also mitigates environmental impacts associated with battery disposal. - Pharmaceuticals: API purification, solvent extraction

In the pharmaceutical industry, ensuring the purity of Active Pharmaceutical Ingredients (APIs) is essential for the safety and effectiveness of drugs. Solvent extraction plays a pivotal role in this process. First, the crude API mixture is dissolved in a suitable solvent. Different solvents are then used to selectively extract impurities or isolate the desired API. This is based on the differences in solubility and chemical properties. After extraction, further purification steps like crystallization and chromatography are carried out. Stringent quality control measures are implemented at each stage to guarantee that the final API product meets the highest purity standards, ultimately ensuring the production of reliable and safe medications. - Environmental: Heavy metal removal from wastewater

Heavy metals in wastewater pose a significant threat to the environment and human health. Our environmental solution focuses on effectively removing these contaminants. We begin by analyzing the wastewater to identify the types and concentrations of heavy metals present, such as lead, mercury, and cadmium. Chemical precipitation methods are often the first line of treatment, where chemicals are added to form insoluble metal compounds that can be separated. Ion - exchange resins and membrane filtration are also utilized to capture remaining metal ions. By treating wastewater to reduce heavy metal levels to acceptable limits, we protect water bodies, prevent soil contamination, and safeguard the overall ecological balance.

Packaging & Transportation

Crush-proof foam and wooden cases ensure safe global delivery.

After-Sales Service

2-year warranty, 48-hour technical response, and on-site training available.

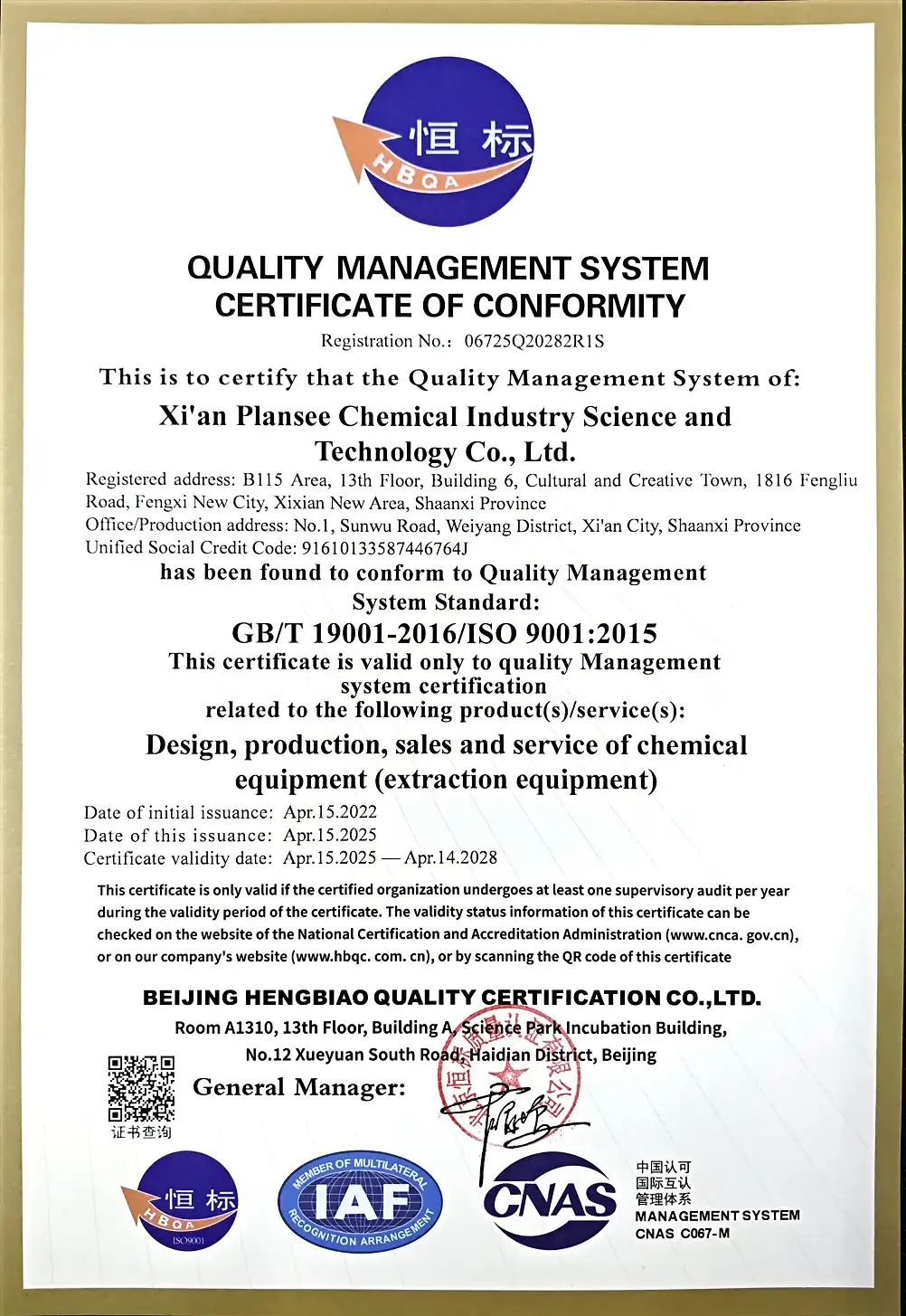

Certifications

ISO 9001, CE, and RoHS compliant.

FAQs

Q: Can I customize mixing volume for nuclear extraction?

A: Yes! We offer 1L–5L shielded units with titanium materials.

Q: Do you provide extraction efficiency data?

A: Absolutely. Request our case studies for rare earth (99.2% efficiency) and lithium (98.5%) benchmarks.

Q: What's the lead time for a 3L model?

A: 15–20 days for standard configurations.

Q: Are your devices GMP-compatible?

A: Yes. SUS316L models meet Pharma Grade 3A standards.

Q: Do you accept lease-to-own agreements?

A: Yes! Contact us for flexible payment plans.

Contact Us

Ready to upgrade your lab's extraction process? Email wangzhijun@cuiyan-tec.com for a free quote or demo video of laboratory mixer settlers.