Equipment For Liquid Liquid Extraction

Configuration:desktop base edition, mobile standard edition, environmentally friendly high edition

Mixing volumn: 200ml, 300ml, 500ml, 1L, 2L, 3L or customized

Plate thickness:5mm,6mm,8mm,10mm

Material: PP,PPH,PVC,transparent PVC,PMMA,PTFE,PEEK,SUS,Ti

Production process: welding,bonding,bending,injection molding,integral forming

Optional function: temperature control device, pH adjustment device, water-bath jacket device, anti-overflow tank device,watch window device

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable mixer-settler stage amount, adjustable agitator speed, and adjustable phase interface height;Highly customizable

Application:rare earth extraction;nickel cobalt extraction;rubidium cesium extraction;salt lake brine extraction;nuclear extraction;isotope extraction;lithium battery recycling;vanadium battery recycling;copper electroplate recycling;biological wastewater recycling

- Product Description

Shaanxi Cuiyan: Your Trusted Equipment For Liquid Liquid Extraction Manufacturer & Supplier

As a leading Equipment For Liquid Liquid Extraction manufacturer since 2012, Shaanxi Cuiyan Technology Co., Ltd combines innovation with industrial expertise. Our lab-scale mixer settlers are engineered for high extraction rates, leak-proof operation, and seamless integration with automation systems. With over 10,000 stages sold globally and 300+ satisfied clients, we deliver scalable, energy-efficient solutions tailored to your lab or pilot needs.

Equipment For Liquid Liquid Extraction Specifications

| Specifications | Details |

|---|---|

| Configurations | Desktop Base Edition, Mobile Standard Edition, Environmentally Friendly High Edition |

| Mixing Volume | 200ml, 300ml, 500ml, 1L, 2L, 3L (Customizable) |

| Plate Thickness | 5mm, 6mm, 8mm, 10mm |

| Material Options | PP, PPH, PVC, Transparent PVC, PMMA, PTFE, PEEK, SUS, Ti |

| Production Process | Welding, Bonding, Bending, Injection Molding, Integral Forming |

| Optional Functions | Temperature Control, pH Adjustment, Water-Bath Jacket, Anti-Overflow Tank, View Window |

Why Choose Our Equipment for Liquid-Liquid Extraction?

- Smart Automation: Integrate sensors (temperature, pH, liquid level) for precise process control.

- Anti-Bubbling Design: One-step tank filling/emptying reduces operational downtime.

- Modular & Scalable: Quickly expand or reconfigure stages to match evolving workflows.

- Corrosion Resistance: SUS/Ti materials ensure durability in harsh chemical environments.

- Patented Technology: 9+ national patents validate our R&D excellence.

Material & Processing Excellence

Our equipment for liquid-liquid extraction uses industry-grade polymers (PP, PTFE) and metals (SUS 316, titanium) to resist acids, alkalis, and organic solvents. Advanced techniques like integral forming eliminate weak joints, while transparent PVC/PMMA tanks let you monitor phase separation visually.

Key Functions

- Adjustable agitator speed (50–800 RPM) for optimal mixing.

- Interchangeable settler plates to fine-tune phase interface height.

- Optional water-bath jackets maintain stable temperatures (±1°C).

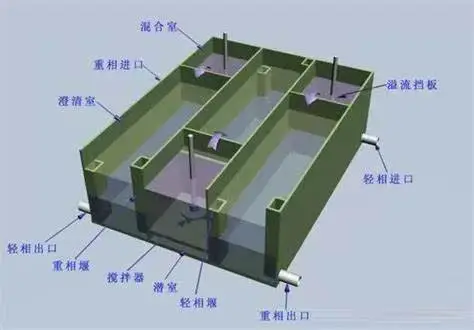

How It Works

The mixer settler achieves Equipment For Liquid Liquid Extraction in two stages:

- Mixing: Agitation creates a high-surface-area emulsion for rapid mass transfer.

- Settling: Gravity separates immiscible phases based on density differences.

Our design minimizes cross-stage contamination, ensuring >95% extraction efficiency.

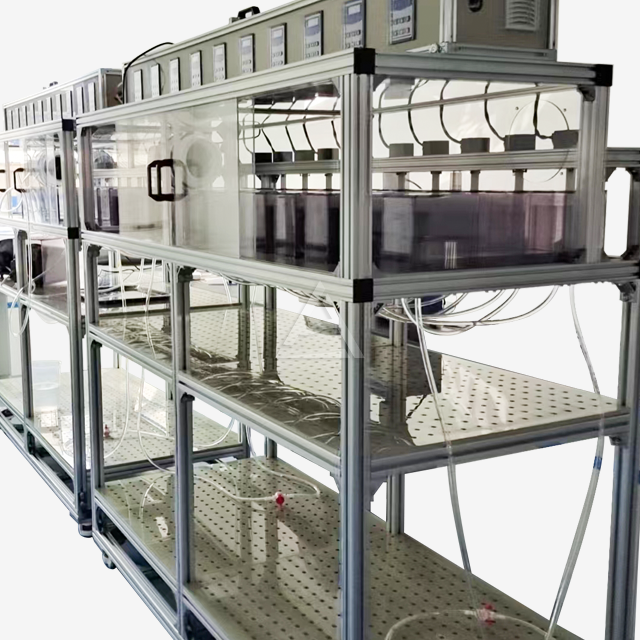

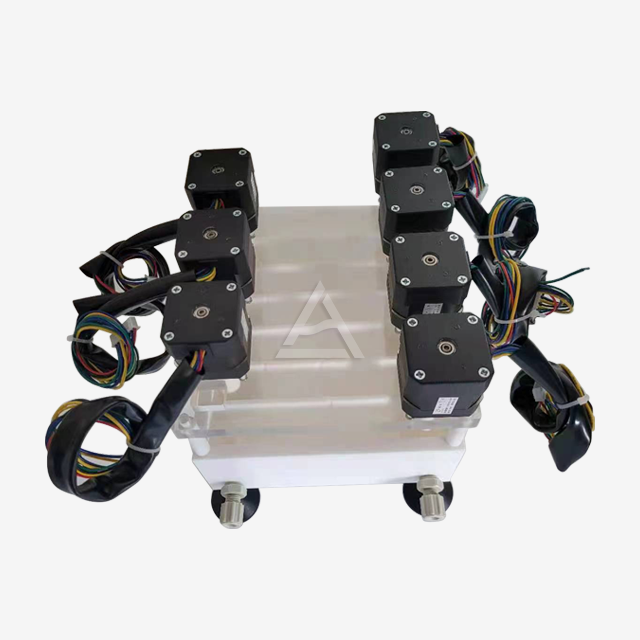

Physical Display

This section features a genuine product showcase. The images display the product’s appearance in detail. Contact us if you need more info.

User Guide

- Setup

Begin the setup by choosing a suitable location and firmly mounting the unit. Ensure it is level to prevent operational disruptions. Connect the sensors, which could measure variables like temperature, pressure, or flow rate, and integrate the automation components. This might involve hooking up control modules to regulate processes automatically. After connection, calibration is crucial. Use reference standards to adjust the settings of the sensors and any relevant internal parameters. Precise calibration guarantees accurate data collection and smooth operation of the automated functions, laying a solid foundation for the unit's performance. - Operation

For operation, carefully load the feed solutions into the unit, adhering to safety protocols and proper handling procedures. Once loaded, initiate the agitation process. The agitation speed can be adjusted based on the nature of the solutions, with more viscous substances often requiring higher speeds. Continuously monitor the process through the view windows. Observe the mixing behavior, the formation of any precipitates, or the separation of phases. This visual inspection allows for real - time detection of any irregularities, enabling prompt adjustments to optimize the process. - Maintenance

Regular maintenance is essential for the longevity of the unit. After each use, clean it thoroughly with compatible solvents. These solvents are carefully selected to dissolve residues without causing damage to the unit's components. Annually, replace the O - rings. Over time, O - rings can degrade due to exposure to chemicals, heat, or mechanical stress. Replacing them ensures a tight seal, preventing leaks that could compromise the unit's performance and potentially lead to safety hazards or process inefficiencies.

Application Areas

- Rare Earth & Battery Recycling: Lithium, cobalt, nickel recovery.

- Pharmaceuticals: API purification, solvent extraction.

- Environmental: Heavy metal removal from wastewater.

- Nuclear & Mining: Uranium/vanadium separation, salt lake brine processing.

Packaging & Transportation

Crush-proof, climate-controlled packaging ensures safe global delivery.

After-Sales Service

24/7 technical support, 2-year warranty, and lifetime maintenance guidance.

Qualification Certification

ISO 9001, CE, and REACH compliance guarantees quality and safety.

FAQ

Q:Can I customize mixing volumes?

A:Yes! We offer volumes from 200ml to 3L, with bespoke designs available.

Q:Are your materials FDA-compliant?

A:PP, PTFE, and SUS 316 meet FDA/GMP standards for pharmaceutical use.

Q:What's the lead time?

A:Standard units ship in 2 weeks; customized orders take 4–6 weeks.

Q:Is the equipment compatible with my existing setup?

A:Our modular design integrates with most automation systems (SIEMENS, Rockwell).

Q:How energy-efficient is it?

A:Low-power motors and insulation reduce energy use by 30% vs. conventional models.

Contact Us

Elevate your extraction processes with Xi'an Plansee's Equipment For Liquid Liquid Extraction. Email wangzhijun@cuiyan-tec.com to discuss your project or request a demo!

VIEW MORECounter Current Extractor

VIEW MORECounter Current Extractor VIEW MORELiquid Liquid Mixer Settler

VIEW MORELiquid Liquid Mixer Settler VIEW MOREBox Type Mixer Settler

VIEW MOREBox Type Mixer Settler VIEW MOREBonding Mixer Settler

VIEW MOREBonding Mixer Settler VIEW MOREVanadium Battery Industry Mixer Settler

VIEW MOREVanadium Battery Industry Mixer Settler VIEW MORECopper Electroplating Industry Mixer Settler

VIEW MORECopper Electroplating Industry Mixer Settler VIEW MOREMicro Isotope Extraction System

VIEW MOREMicro Isotope Extraction System VIEW MOREMixer Settler Systems

VIEW MOREMixer Settler Systems