Liquid Liquid Mixer Settler

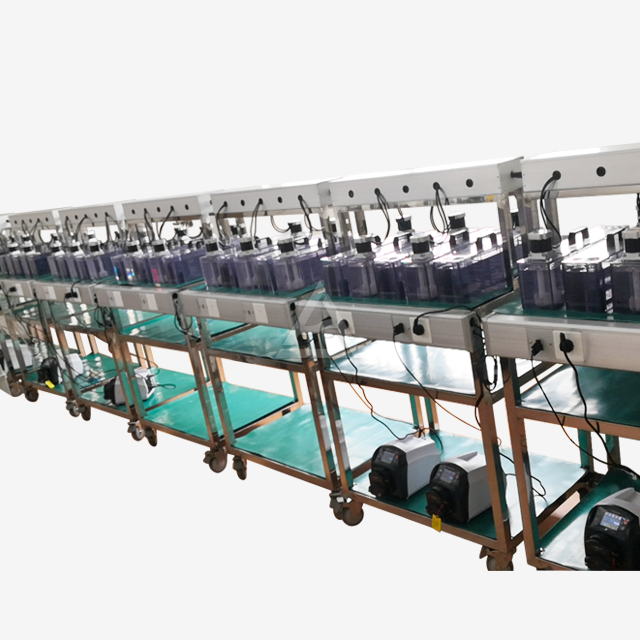

Configuration:desktop base edition, mobile standard edition, environmentally friendly high edition

Mixing volumn: 200ml, 300ml, 500ml, 1L, 2L, 3L or customized

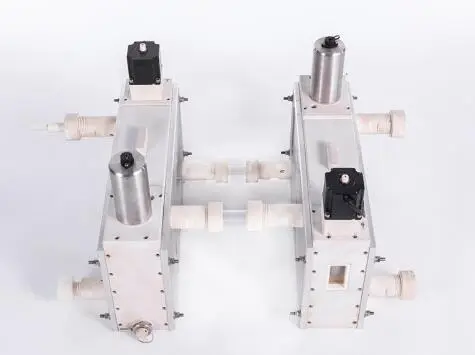

Plate thickness:5mm,6mm,8mm,10mm

Material: PP,PPH,PVC,transparent PVC,PMMA,PTFE,PEEK,SUS,Ti

Production process: welding,bonding,bending,injection molding,integral forming

Optional function: temperature control device, pH adjustment device, water-bath jacket device, anti-overflow tank device,watch window device

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable mixer-settler stage amount, adjustable agitator speed, and adjustable phase interface height;Highly customizable

Application:rare earth extraction;nickel cobalt extraction;rubidium cesium extraction;salt lake brine extraction;nuclear extraction;isotope extraction;lithium battery recycling;vanadium battery recycling;copper electroplate recycling;biological wastewater recycling

- Product Description

Shaanxi Cuiyan: Your Trusted Liquid Liquid Mixer Settler Manufacturer & Supplier

Shaanxi Cuiyan Technology Co., Ltd, established in 2012, is a leading Liquid Liquid Mixer Settler manufacturer & supplier specializing in lab, pilot, and industrial-scale extraction equipment. With 37+ experts from top Chinese universities and 10,000+ stages sold globally, our mixers deliver high corrosion resistance, modular flexibility, and unmatched extraction efficiency — trusted by 300+ clients in rare metals, nuclear, and green chemistry sectors.Ideal for R&D and small-batch production, our lab-scale prouct ensures precise solvent extraction, phase separation, and process optimization. Customizable configurations and materials adapt to diverse chemical environments.

Liquid Liquid Mixer Settler Specifications

| Specifications | Options |

|---|---|

| Configuration | Desktop Base, Mobile Standard, Eco-Friendly High Edition |

| Mixing Volume | 200ml–3L (Customizable) |

| Plate Thickness | 5mm–10mm |

| Material | PP, PPH, PVC, Transparent PVC, PMMA, PTFE, PEEK, SUS, Ti |

| Production Process | Welding, Bonding, Bending, Injection Molding, Integral Forming |

| Optional Functions | Temperature Control, pH Adjustment, Anti-Overflow Tank, Water-Bath Jacket |

Why Choose Our Liquid Liquid Mixer Settler?

- High Extraction Efficiency: Achieve 99%+ separation accuracy for rare earths, lithium, or nuclear materials.

- Corrosion-Resistant Materials: SUS 316L, PTFE, and titanium options for aggressive acids or solvents.

- Modular & Scalable: Combine stages for process expansion — perfect for pilot-to-production scaling.

- Smart Customization: Integrate sensors (pH, temperature) or one-step tank filling/emptying systems.

Material & Processing Excellence

We use PP, PTFE, and titanium for unmatched chemical resistance. Processes like CNC welding and injection molding ensure leak-proof, durable designs.

Key Functions

- Adjustable agitator speed (50–500 RPM) for optimal mixing.

- Interchangeable settling plates to control phase separation time.

- Anti-bubbling technology for stable operation.

How It Works

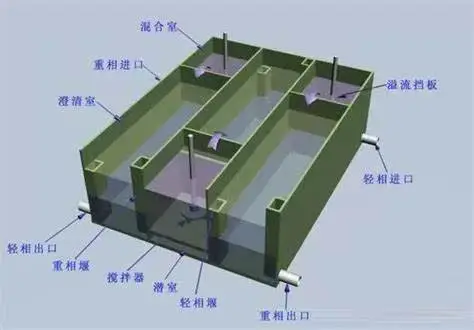

- Mixing Stage: Two immiscible liquids (e.g., organic solvent + metal-rich aqueous phase) blend in the mixer.

- Settling Stage: Mixed phases flow into the settler, where gravity separates them based on density.

- Collection: Purified components exit through dedicated outlets.

Applications

- Metals: Rare earths, nickel, cobalt, lithium.

- Nuclear: Uranium/plutonium recovery.

- Recycling: Lithium-ion batteries, copper electroplating.

- Pharma: API extraction, solvent recovery.

User Guide

- Setup

The setup process commences with carefully selecting a stable and appropriate location to mount the unit. Ensure the surface can support the unit's weight and vibrations during operation. Use the provided mounting brackets and hardware to secure it firmly. Next, connect the feed lines, following the detailed installation diagrams. Make certain all connections are tight to prevent leaks. Finally, calibrate the sensors. Use standard reference materials and follow the calibration procedures in the user manual. This ensures accurate readings for parameters such as temperature, pressure, and flow rate, laying the foundation for smooth operation. - Operation

Once setup is complete, operation begins at the control panel. Here, you can precisely set the mixer speed according to the nature of the substances being processed. For less viscous materials, a lower speed may be sufficient for gentle blending, while more viscous substances require a higher speed for effective mixing. Simultaneously, adjust the phase interface height. This is crucial in processes involving immiscible liquids, as it determines the separation efficiency. Continuously monitor and fine - tune these settings as the operation progresses to achieve optimal results. - Maintenance

Maintenance is key to the long - term performance of the unit. Regularly clean the unit using non - abrasive agents. These agents effectively remove residue from previous processes without scratching or damaging the unit's surfaces. After cleaning, rinse thoroughly to ensure no cleaning agent remains. Additionally, conduct a monthly inspection of the seals. Check for signs of wear, such as cracks or leaks. If any issues are detected, promptly replace the seals. This proactive maintenance approach helps prevent leaks, extends the unit's lifespan, and ensures consistent operation.

FAQ

Q: Can you customize mixers for high-viscosity fluids?

A: Yes! We adjust agitator designs and settling plates for viscous media like polymer solutions.

Q: What's the lead time for a custom order?

A: 4–6 weeks, depending on material availability.

Q: Do your mixers comply with ATEX/ISO standards?

A: Absolutely. We provide certifications for hazardous environments.

Q: How do I prevent leakage?

A: Our double-sealed joints and laser-welded tanks ensure zero leaks.

Q: Can I upgrade my lab unit to industrial scale later?

A: Yes! Modular designs allow seamless capacity expansion.

Contact Us

Need a liquid liquid mixer settler tailored to your process? Email wangzhijun@cuiyan-tec.com for a quote or technical consultation.