Mixer Settler Liquid Liquid Extraction

Configuration:desktop base edition, mobile standard edition, environmentally friendly high edition

Mixing volumn: 200ml, 300ml, 500ml, 1L, 2L, 3L or customized

Plate thickness:5mm,6mm,8mm,10mm

Material: PP,PPH,PVC,transparent PVC,PMMA,PTFE,PEEK,SUS,Ti

Production process: welding,bonding,bending,injection molding,integral forming

Optional function: temperature control device, pH adjustment device, water-bath jacket device, anti-overflow tank device,watch window device

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable mixer-settler stage amount, adjustable agitator speed, and adjustable phase interface height;Highly customizable

Application:rare earth extraction;nickel cobalt extraction;rubidium cesium extraction;salt lake brine extraction;nuclear extraction;isotope extraction;lithium battery recycling;vanadium battery recycling;copper electroplate recycling;biological wastewater recycling

- Product Description

Shaanxi Cuiyan: Your Trusted Mixer Settler Liquid Liquid Extraction Manufacturer & Supplier

Shaanxi Cuiyan Technology Co., Ltd, established in 2012, is a leading mixer settler liquid liquid extraction manufacturer and supplier specializing in lab, pilot, and industrial-scale equipment. With 37+ experts, 9,000+ stages sold, and 300+ global clients, we deliver highly customizable, corrosion-resistant systems optimized for efficiency, scalability, and compliance.

Mixer Settler Liquid Liquid Extraction Description

Our mixer settler liquid liquid extraction is engineered for precise separation in research and small-batch production. Designed with modularity and automation, they adapt seamlessly to industries like rare metal recovery, pharmaceuticals, and battery recycling.

Specifications

| Parameter | Options |

|---|---|

| Configuration | Desktop Base, Mobile Standard, Environmentally Friendly High Edition |

| Mixing Volume | 200mL–3L (Customizable) |

| Plate Thickness | 5mm–10mm |

| Material | PP, PPH, PVC, Transparent PVC, PMMA, PTFE, SUS, Ti |

| Production Process | Welding, Bonding, Bending, Injection Molding, Integral Forming |

| Optional Functions | Temperature Control, pH Adjustment, Anti-Overflow Tank, Watch Window |

Why Choose Our Mixer Settler Liquid Liquid Extraction Equipment?

- Industry-Leading Efficiency: Achieve >95% extraction rates with adjustable agitator speeds and phase interface control.

- Custom-Built Flexibility: Tailor mixing volumes, materials, and functions (e.g., integrated sensors) to your process.

- Durability Meets Design: Corrosion-resistant materials and modular structures ensure longevity in harsh environments.

- Patent-Backed Innovation: 10+ national patents support our high-efficiency extraction technology.

Material & Processing Excellence

Choose from PP for chemical resistance, transparent PVC for real-time monitoring, or SUS/Ti for extreme conditions. Our advanced bonding and injection molding techniques eliminate leakage risks while maintaining structural integrity.

Key Functions

- Anti-Bubbling Design: Minimize phase contamination.

- One-Step Tank Filling/Emptying: Simplify operation.

- Energy-Saving Automation: Reduce power consumption by up to 30%.

How It Works

- Mixing Stage: Agitators disperse one liquid phase into another, enabling mass transfer.

- Settling Stage: Immiscible phases separate naturally by density in the settler zone.

- Interface Control: Adjustable weirs maintain optimal separation clarity.

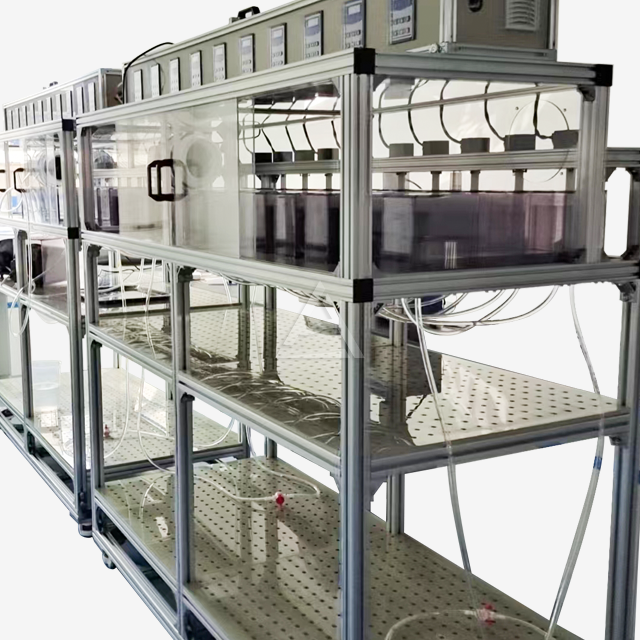

Physical Display

These are physical displays of our mixer settler liquid liquid extraction. You can get a visual understanding of them through clear pictures. We are also ready to provide you with detailed information and answer any questions you may have.

User Guide

- Setup

The setup process is designed for maximum convenience and speed. Our modular system allows you to assemble the stages either vertically or horizontally, depending on your available space and operational requirements. With clear, step - by - step instructions and pre - aligned connection points, you can complete the assembly within just 30 minutes. This quick setup time minimizes downtime and gets your system up and running promptly, whether it's for a new installation or a reconfiguration. - Operation

Once set up, operation is a breeze with the intuitive touchscreen interface. Here, you can easily set the agitation speed anywhere from 100 to 1,200 RPM. Tailor the speed to the viscosity of the substances you're processing; lower speeds for gentle mixing of delicate materials and higher speeds for more viscous fluids or when enhanced mixing is needed. Simultaneously, the touchscreen provides real - time monitoring of crucial parameters like pH and temperature. This enables you to closely observe and control the process for optimal results. - Maintenance

Maintenance is crucial for the long - term performance of the equipment. Regularly clean the unit using non - abrasive agents to effectively remove residue from previous processes without scratching or damaging the surfaces. After cleaning, thoroughly rinse to ensure no cleaning agent remains. Additionally, conduct a quarterly inspection of the seals. Check for signs of wear, such as cracks, swelling, or leaks. If any issues are detected, promptly replace the seals to maintain the integrity of the system and prevent any potential leaks that could disrupt operations.

Application Areas

- Rare Earth & Battery Recycling: Extract lithium, cobalt, nickel from ores or spent batteries.

- Pharmaceuticals: Purify APIs with GMP-compliant designs.

- Wastewater Treatment: Remove heavy metals (e.g., copper, vanadium) to meet EPA standards.

Packaging & Transportation

Equipment is shock-proofed with foam and crated for global shipping.

After-Sales Service

24/7 technical support, 2-year warranty, and on-site training available.

Qualification Certification

ISO 9001, CE, and REACH certified.

FAQ

Q: Can you customize equipment for high-viscosity fluids?

A: Yes! We adjust agitator torque and settler dimensions to handle viscosities up to 5,000 cP.

Q: Which material suits acidic environments?

A: PTFE or PPH provides superior resistance to acids like HCl or H2SO4.

Q: Is automation compatible with existing PLC systems?

A: Our control modules integrate with Siemens, Allen-Bradley, and more.

Q: What's the lead time for a custom order?

A: Typically 4–6 weeks, depending on complexity.

Q: Do you provide CFD simulations for process validation?

A: Yes – our engineers optimize flow patterns digitally before production.

Contact Us

Elevate your extraction process with Xi'an Plansee's expertise. Email wangzhijun@cuiyan-tec.com for a quote or consultation of Mixer Settler Liquid Liquid Extraction.

VIEW MOREMetal Mixer Settler

VIEW MOREMetal Mixer Settler VIEW MOREAutomated Extraction System

VIEW MOREAutomated Extraction System VIEW MORECounter Current Liquid Liquid Extraction

VIEW MORECounter Current Liquid Liquid Extraction VIEW MORECounter Current Extractor

VIEW MORECounter Current Extractor VIEW MOREBonding Mixer Settler

VIEW MOREBonding Mixer Settler VIEW MORESalt Lake Brine Industry Mixer Settler

VIEW MORESalt Lake Brine Industry Mixer Settler VIEW MOREPilot Mixer Settler

VIEW MOREPilot Mixer Settler VIEW MORELiquid Liquid Extraction Equipment Laboratory

VIEW MORELiquid Liquid Extraction Equipment Laboratory