Pilot Mixer Settler

Configuration:mobile platform edition, skid mounted edition

Mixing volumn: 8L,10L,20L,40L,60L,80L or customized

Plate thickness:8mm,10mm,12mm,15mm

Material: PP,PPH,PVC,transparent PVC,PMMA

Production process: welding,bonding

Optional function: temperature control device, pH adjustment device, anti-overflow tank device,watch window device

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable mixer-settler stage amount, adjustable agitator speed, and adjustable phase interface height;Highly customizable

Application:rare earth extraction;nickel cobalt extraction;rubidium cesium extraction;salt lake brine extraction;nuclear extraction;vanadium battery recycling;copper electroplate recycling;biological wastewater recycling

- Product Description

Shaanxi Cuiyan: Your Trusted Pilot Mixer Settler Manufacturer & Supplier

As a leading pilot mixer settler manufacturer & supplier, Shaanxi Cuiyan Technology combines 12+ years of expertise with innovative engineering. Our equipment excels in automation integration, energy-saving modular designs, and customizable functions (e.g., anti-bubbling, sensor integration). With 300+ global clients and 10,000+ stages delivered, we ensure scalable, corrosion-resistant solutions for seamless lab-to-industrial transitions.

Pilot Mixer Settler Description

The pilot mixer settler is a compact, modular extraction system designed for process optimization, material recovery, and small-batch production. Ideal for industries requiring precise phase separation and adaptable scalability, it bridges lab research and full-scale manufacturing.

Specifications

| Parameter | Options |

|---|---|

| Configuration | Mobile Platform Edition, Skid-Mounted Edition |

| Mixing Volume | 8L, 10L, 20L, 40L, 60L, 80L (Customizable) |

| Plate Thickness | 8mm, 10mm, 12mm, 15mm |

| Material | PP, PPH, PVC, Transparent PVC, PMMA |

| Production Method | Welding, Bonding |

| Optional Features | Temperature Control, pH Adjustment, Anti-Overflow Tank, Watch Window |

Why Choose Our product?

- High Extraction Rate: Achieve 95%+ separation efficiency with adjustable agitator speeds.

- Zero Leakage: Robust PP/PVC construction resists acids, alkalis, and organic solvents.

- Modular Flexibility: Easily add/remove stages to match evolving process needs.

- Smart Customization: Integrate IoT sensors (pH, temperature) for real-time data tracking.

Material & Processing

Crafted from corrosion-resistant polymers (PP, PVC) or transparent PMMA for visual monitoring, our mixer settlers use CNC-machined components and laser-welded joints for durability. Optional PTFE coatings enhance chemical resistance for harsh environments.

Key Functions

- Precise phase interface control.

- Bubble-free mixing via optimized impeller design.

- Rapid tank filling/emptying with anti-splash features.

- Compatibility with automated control systems.

How It Works

The pilot mixer settler operates in two stages:

- Mixing Zone: Agitators blend immiscible liquids (e.g., organic/aqueous phases) to transfer target compounds.

- Settling Zone: Gravity separates phases into distinct layers, collected via adjustable weirs.

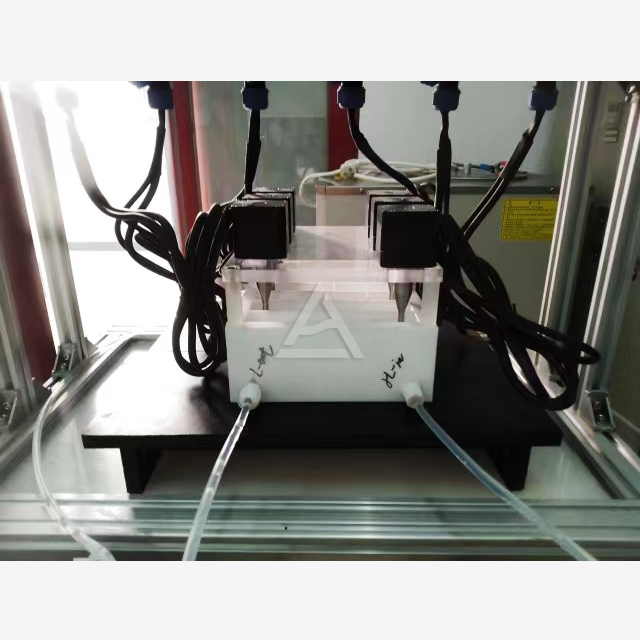

Physical Display

Displayed here are actual product units. Images provide a clear look at their form and build quality. For more information, our team is just a message away.

User Guide

- Setup: Assemble stages vertically/horizontally per space constraints.

- Calibration: Adjust agitator RPM (100–500 rpm) via digital interface.

- Maintenance: Clean channels with 5% nitric acid monthly.

Applications

- Rare earth & nickel - cobalt extraction

Rare earth elements like neodymium and dysprosium, along with nickel - cobalt, are extracted through intricate processes. From ores, crushing and grinding are initial steps to expose the valuable metals. Chemical leaching, often with acids, dissolves these elements. For rare earths, solvent extraction techniques using specialized organic compounds are employed to separate them from impurities. Nickel - cobalt extraction may involve additional electrolytic methods. These metals are crucial for high - tech applications such as in magnets for electric vehicles (rare earths) and in batteries (nickel - cobalt). - Nuclear waste treatment

Nuclear waste treatment is a complex and highly regulated process. It starts with the segregation of different types of nuclear waste, including high - level and low - level waste. High - level waste, which contains highly radioactive substances, is often treated through methods like vitrification. In this process, the waste is mixed with glass - forming materials and heated to form a stable, solid glass - like substance that can be safely stored. Low - level waste may be treated by encapsulation or incineration under strict safety protocols to reduce its volume and radioactivity before disposal. - Lithium battery recycling (e.g., vanadium, copper)

Lithium battery recycling focuses on retrieving valuable metals like vanadium and copper. First, spent batteries are mechanically dismantled to separate components. Chemical leaching is then used to dissolve the metals from the battery materials. For vanadium and copper, specific reagents are added during leaching to enhance solubility. After that, techniques such as solvent extraction and electrolysis are applied to purify and isolate these metals. The recycled metals can be reused in new battery manufacturing, reducing environmental impact and dependence on virgin mining. - Biopharmaceutical wastewater purification

Biopharmaceutical wastewater contains a complex mix of organic compounds, biological materials, and potentially harmful substances. Purification begins with physical separation methods like filtration to remove large particles. Biological treatment follows, where microorganisms break down organic matter. Advanced oxidation processes may be used to destroy persistent organic pollutants. Specialized resin - based systems can also be employed to remove specific contaminants. The purified water must meet strict environmental and safety standards before being discharged or reused in the manufacturing process.

Packaging & Transportation

Shock-proof crating with GPS-tracked global shipping.

After-Sales Service

2-year warranty + lifetime technical support.

Certifications

CE, ISO 9001, and 12+ national patents.

FAQ

Q: Can this handle high-viscosity fluids?

A: Yes! Custom impeller designs ensure efficient mixing even for viscosities up to 1,000 cP.

Q: Is CE certification available?

A: All units meet CE, ISO 9001, and ASME standards.

Q: What's the lead time for a custom design?

A: Typically 6–8 weeks, including prototyping and testing.

Q: Do you offer remote troubleshooting?

A: Yes – our team provides 24/7 support via video calls.

Q: Can I upgrade to industrial-scale later?

A: Absolutely! Modular designs allow seamless capacity expansion.

Contact Us

Ready to optimize your extraction process? Email wangzhijun@cuiyan-tec.com for a free consultation or request a 3D model of your customized pilot mixer settler.