Micro Mixer Settler Unit

Configuration:simple desktop platform edition

Mixing volumn: 20ml, 25ml, 50ml, 80ml, 100ml, 125ml or customized

Wall thickness:8mm,10mm,12mm

Material: PMMA,PTFE,PEEK,Ti

Production process: CNC integral forming

Matching equipment: Optional micro injection pump

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable mixer-settler stage amount, adjustable agitator speed;Highly customizable

Application:nuclear extraction industry;isotope extraction industry;solvent extraction agent industry

- Product Description

Shaanxi Cuiyan: Your Trusted Micro Mixer Settler Unit Manufacturer & Supplier

Shaanxi Cuiyan Technology Co., Ltd, established in 2012, specializes in advanced extraction equipment for chemical, nuclear, and environmental industries. Our micro mixer settler units combine cutting-edge automation, modular design, and 9+ patented technologies to deliver unmatched corrosion resistance, scalability, and energy efficiency. With 300+ global clients and 10,000+ stages sold, we ensure reliable, customizable solutions for lab-to-production needs.

Micro Mixer Settler Unit Description

Our micro mixer settler unit is engineered for precision liquid-liquid extraction in small-scale research or pilot projects. Designed with CNC-machined materials and adaptable configurations, it ensures leak-free operation, high separation efficiency, and seamless integration with automation systems.

Specifications

| Parameter | Details |

|---|---|

| Mixing Volume | 20ml, 25ml, 50ml, 80ml, 100ml, 125ml (Customizable) |

| Wall Thickness | 8mm, 10mm, 12mm |

| Material Options | PMMA, PTFE, PEEK, Titanium |

| Production Process | CNC Integral Forming |

| Agitator Speed | Adjustable (0-500 RPM) |

| Matching Equipment | Optional Micro Injection Pump |

Why Choose Our product?

- High Customization: Tailor stages, materials, and sensor integration (pH, temperature, liquid level).

- Zero Leakage: Precision-engineered seals and robust materials like PTFE/PEEK ensure chemical resistance.

- Modular Design: Rapid assembly/disassembly for multi-stage expansion or process adjustments.

- Energy Efficiency: 30% lower energy use vs. traditional units, ideal for green chemistry.

- Smart Automation: IoT-ready for remote monitoring and data logging.

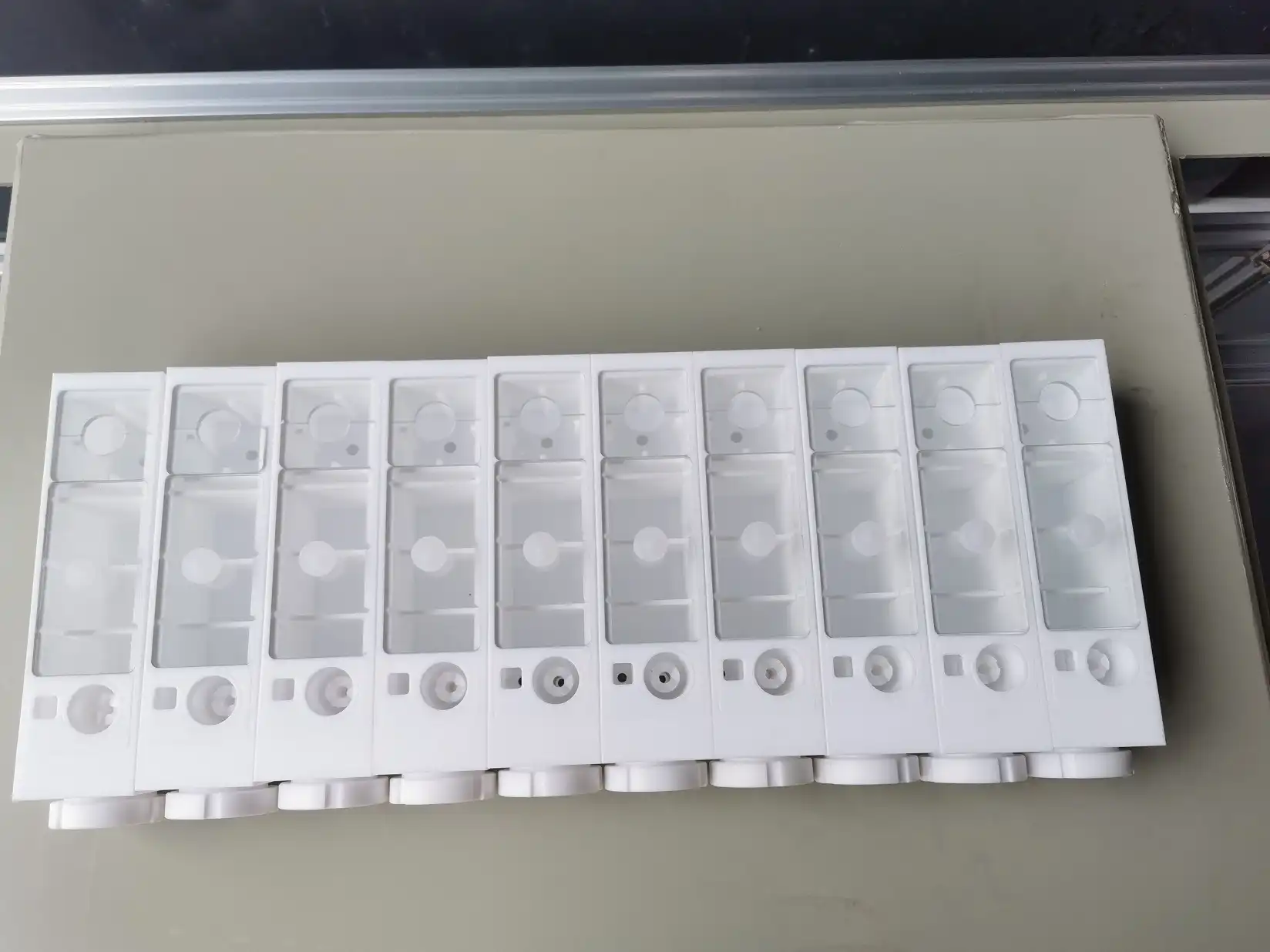

Material & Processing Method

Crafted from CNC-machined PMMA, PTFE, or Titanium, each unit undergoes rigorous quality checks to ensure durability against aggressive solvents (e.g., nitric acid, kerosene). The seamless, bubble-free structure minimizes dead zones, enhancing extraction rates by up to 95%.

How It Works

- Mixing Stage: Adjustable agitators blend two immiscible liquids (e.g., organic/aqueous phases).

- Settling Stage: Laminar flow design accelerates phase separation within minutes.

- Output: Purified extract flows to the next stage or collection vessel.

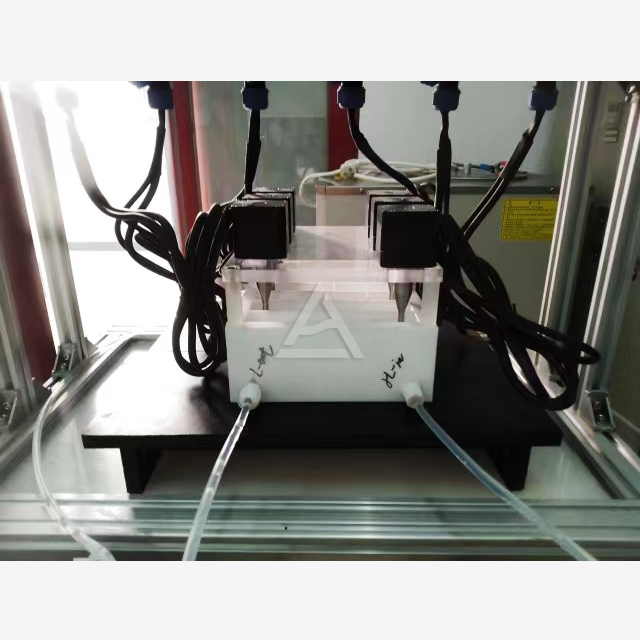

Physical Display

The visuals on this page show authentic micro mixer settler unit from our production line. For more details or technical consultation, feel free to contact us directly.

User Guide

- Setup: Mount the unit on a stable bench. Connect tubing and optional sensors.

- Calibration: Adjust agitator speed via digital controller.

- Operation: Feed liquids via peristaltic pump; monitor separation via sight glasses.

- Maintenance: Rinse with deionized water after use; inspect seals monthly.

Applications

- Nuclear Fuel Reprocessing: Extract uranium/plutonium from spent fuel

Nuclear fuel reprocessing is a complex yet crucial process. Spent nuclear fuel, which still contains valuable uranium and plutonium, is first carefully transported to specialized facilities. Here, through a series of chemical separation techniques, such as solvent extraction, uranium and plutonium are selectively removed from the highly radioactive waste matrix. The extracted uranium can be recycled for use in new nuclear fuel, while plutonium may be either reused in certain types of reactors or disposed of safely. This process not only recovers valuable resources but also helps in reducing the volume and long - term radioactivity of nuclear waste. - Pharmaceuticals: Purify APIs or separate enantiomers

In the pharmaceutical industry, the purification of Active Pharmaceutical Ingredients (APIs) is of utmost importance. APIs must be extremely pure to ensure the safety and effectiveness of drugs. Chromatography techniques, like high - performance liquid chromatography (HPLC), are commonly used. This method separates the API from impurities based on their different affinities for the stationary and mobile phases. When it comes to separating enantiomers (mirror - image isomers of a molecule), chiral chromatography is employed. Enantiomers can have vastly different biological activities, so their separation is critical for developing drugs with precise therapeutic effects and fewer side - effects. - Rare Earth Metallurgy: Recover neodymium, dysprosium from ores

Rare earth metals such as neodymium and dysprosium are essential for many high - tech applications, from electric vehicle motors to wind turbines. In rare earth metallurgy, the process starts with mining the ores, which are often complex mixtures. The ores are first crushed and ground, then subjected to chemical leaching to dissolve the rare earth elements. Solvent extraction and ion - exchange processes are subsequently used to isolate and purify neodymium and dysprosium from other elements present in the leachate. These recovery methods are crucial as they supply the rare earth metals needed to drive the development of clean energy and advanced electronics technologies. - Environmental Testing: Remove heavy metals from wastewater

Environmental testing for wastewater treatment focuses on eliminating harmful heavy metals like lead, mercury, and cadmium. The process typically begins with precipitation, where chemicals are added to the wastewater to form insoluble metal compounds that can be separated by sedimentation or filtration. Ion - exchange resins may also be used, which selectively bind to heavy metal ions and release harmless ions in exchange. Additionally, advanced techniques such as membrane filtration can further purify the water by physically separating the heavy metals. Proper removal of these heavy metals is essential to prevent environmental pollution and protect the health of aquatic ecosystems and humans.

Packaging & Transportation

Units are shipped in anti-static ESD foam, with shockproof crates for international logistics.

After-Sales Service

24/7 technical support, 2-year warranty, and global spare parts network.

Certifications

ISO 9001, CE, and ASME-compliant manufacturing.

FAQ

Q1: Can I integrate this unit into my existing pilot plant?

A:Yes! Our product support standard 1/4" or 1/8" tubing connections.

Q2: Which material suits high-temperature extraction?

A:Titanium (up to 200°C) or PEEK (150°C) for corrosive, high-heat environments.

Q3: How many stages can I combine?

A:Up to 12 stages in series; contact us for large-scale designs.

Q4: Is training provided?

A:Free virtual training + PDF manual included.

Q5: Lead time for customized orders?

A:4-6 weeks (CNC machining + testing).

Contact Us

Elevate your extraction processes with Xi'an Plansee's micro mixer settler unit – where innovation meets reliability. Email wangzhijun@cuiyan-tec.com for a quote or technical consultation!