Mixer Settler Cascade

Configuration:desktop base edition, mobile standard edition, environmentally friendly high edition

Mixing volumn: 200ml, 300ml, 500ml, 1L, 2L, 3L or customized

Plate thickness:5mm,6mm,8mm,10mm

Material: PP,PPH,PVC,transparent PVC,PMMA,PTFE,PEEK,SUS,Ti

Production process: welding,bonding,bending,injection molding,integral forming

Optional function: temperature control device, pH adjustment device, water-bath jacket device, anti-overflow tank device,watch window device

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable mixer-settler stage amount, adjustable agitator speed, and adjustable phase interface height;Highly customizable

Application:rare earth extraction;nickel cobalt extraction;rubidium cesium extraction;salt lake brine extraction;nuclear extraction;isotope extraction;lithium battery recycling;vanadium battery recycling;copper electroplate recycling;biological wastewater recycling

- Product Description

Shaanxi Cuiyan: Your Trusted Mixer Settler Cascade Manufacturer & Supplier

Shaanxi Cuiyan Technology Co., Ltd – a trusted mixer settler cascade manufacturer & supplier since 2012 – combines cutting-edge R&D, modular designs, and 12+ years of industry expertise. With over 10,000 stages sold globally, our equipment excels in automation, corrosion resistance, and energy efficiency, tailored for rare metal extraction, nuclear processing, and sustainable recycling.A precision-engineered system for liquid-liquid extraction, ideal for industries requiring high separation efficiency, scalability, and adaptability.

Mixer Settler Cascade Specifications

| Specifications | Details |

|---|---|

| Configuration | Desktop Base, Mobile Standard, Eco-Friendly High Edition |

| Mixing Volume | 200mL–3L (Customizable) |

| Plate Thickness | 5–10mm |

| Material Options | PP, PPH, PVC, SUS, Ti, PTFE, PMMA |

| Production Process | Welding, Injection Molding, Integral Forming |

| Optional Features | pH/Temperature Control, Anti-Overflow Tank, Watch Window |

Why Choose Our product?

- Automation Ready: Integrate PLC/DCS systems for precise phase separation.

- Corrosion-Resistant: SUS316 and PTFE materials handle acidic/alkaline environments.

- Modular Design: Scale from lab to industrial production seamlessly.

- Energy-Saving: Low solvent consumption reduces operational costs.

- Customizable: Add sensors (pH, temperature) or tailor tank dimensions.

Material & Processing Excellence

- PP/PPH: Lightweight, cost-effective for low-corrosion applications.

- SUS/Ti: For nuclear or high-purity metal extraction (e.g., lithium, cobalt).

- PTFE/PMMA: Transparent tanks enable real-time monitoring.

- Precision Crafting: Laser-cut components and robotic welding ensure leak-proof performance.

How It Works

The mixer settler cascade separates liquids via agitation (mixer) and gravity-based settling (clarifier). Adjustable impellers control droplet size, while weir plates maintain stable phase interfaces.

Applications

- Metals: Rare earth, nickel, cobalt, rubidium extraction.

- Energy: Lithium battery recycling, vanadium processing.

- Environmental: Heavy metal recovery (e.g., copper electroplating waste).

- Nuclear: Uranium/plutonium separation.

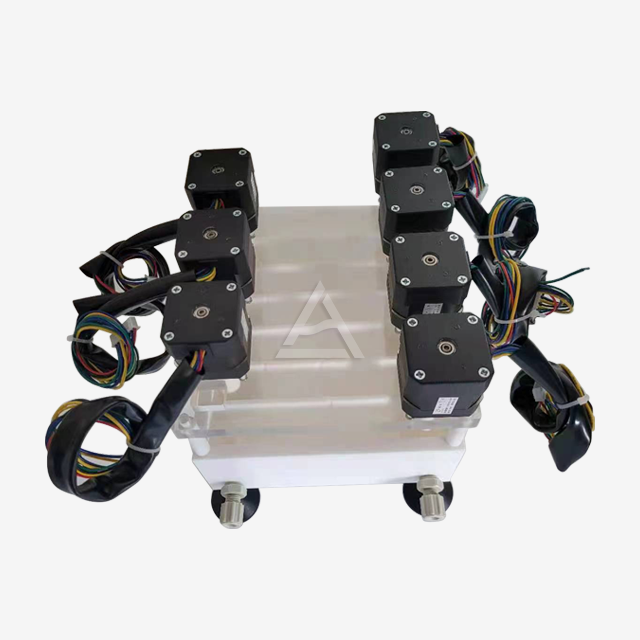

Physical Display

We're showcasing high-grade machines. You can review detailed images to see how they function in practice.

User Guide

- Setup

For the setup, begin by carefully choosing a flat and leveled ground area. Uneven surfaces can lead to operational inefficiencies and potential equipment damage. Unpack each module, making sure all components are accounted for. Then, following the detailed assembly manual, start piecing together the modules. Use appropriate tools to secure connections tightly. This step - by - step process ensures a stable and properly configured setup, which is fundamental for the smooth operation of the entire system. - Calibration

Calibration is a key step in optimizing performance. Access the touchscreen interface, which is designed to be user - friendly. Here, you can precisely set the agitator speed within the range of 100 - 600 RPM. Consider the nature of the substances you'll be processing. For less viscous materials, a lower speed around 100 - 200 RPM may be sufficient for gentle mixing. However, if dealing with more viscous substances, a higher speed, perhaps 400 - 600 RPM, will be required to ensure effective agitation and proper distribution. - Operation

During operation, closely monitor the phase interface through the sight glass. The sight glass provides a clear view of the separation or interaction between different liquid phases. Observe the movement and stability of the interface. Any irregularities, such as excessive turbulence or an unclear separation line, could indicate issues with the mixing process, flow rates, or chemical reactions. By keeping a watchful eye on the phase interface, you can make real - time adjustments to ensure the process runs smoothly and efficiently. - Maintenance

Regular maintenance is crucial for the longevity of the equipment. Every month, clean the unit using non - abrasive solvents. These solvents are effective in removing residue, dirt, and chemical deposits that accumulate during operation. Apply the solvent carefully, using soft brushes or cloths in hard - to - reach areas. After cleaning, thoroughly rinse the unit to ensure no solvent remains. This regular cleaning routine helps to keep the equipment in top condition, reducing the risk of component failure and maintaining optimal performance.

Packaging & Transportation

Crush-proof wooden cases with foam padding. Global shipping via DHL/FedEx (7–15 days).

After-Sales Service

24/7 technical support + 2-year warranty. On-site training available.

Certification

ISO 9001, ASME, CE, and REACH compliant.

FAQs

Q: Can I customize the product for high-temperature processes?

A: Yes! We offer titanium or PTFE-lined tanks stable up to 200°C.

Q: Do you provide ATEX-certified equipment?

A: Absolutely. Our explosion-proof models meet EU/NA standards.

Q: What's the lead time for a 500L system?

A: 4–6 weeks, including factory testing.

Q: Is remote monitoring supported?

A: Yes – integrate IoT sensors for real-time data access.

Q: How to reduce solvent loss?

A: Our anti-foaming design cuts solvent waste by 30%.

Contact Us

Need a mixer settler cascade for your project? Email wangzhijun@cuiyan-tec.com for a quote or technical consultation.

VIEW MORELiquid Liquid Extraction Of Rubidium Cesium

VIEW MORELiquid Liquid Extraction Of Rubidium Cesium VIEW MOREMixer Settler Tank

VIEW MOREMixer Settler Tank VIEW MOREAutomated Mixer Settler

VIEW MOREAutomated Mixer Settler VIEW MORERubidium Cesium Industry Mixer Settler

VIEW MORERubidium Cesium Industry Mixer Settler VIEW MOREBiological Wastewater Industry Mixer Settler

VIEW MOREBiological Wastewater Industry Mixer Settler VIEW MOREMicro Isotope Extraction System

VIEW MOREMicro Isotope Extraction System VIEW MORELiquid Liquid Extraction Process Equipment

VIEW MORELiquid Liquid Extraction Process Equipment VIEW MOREPVC Mixer Settler

VIEW MOREPVC Mixer Settler