Micro Isotope Extraction System

Configuration:simple desktop platform edition

Mixing volumn: 20ml, 25ml, 50ml, 80ml, 100ml, 125ml or customized

Wall thickness:8mm,10mm,12mm

Material: PMMA,PTFE,PEEK,Ti

Production process: CNC integral forming

Matching equipment: Optional micro injection pump

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable mixer-settler stage amount, adjustable agitator speed;Highly customizable

Application:nuclear extraction industry;isotope extraction industry;solvent extraction agent industry

- Product Description

Shaanxi Cuiyan: Your Trusted Micro Isotope Extraction System Manufacturer & Supplier

Shaanxi Cuiyan Technology Co., Ltd – Established in 2012, we specialize in advanced micro isotope extraction systems for industries requiring high-precision separation. With 37+ experts and 10,000+ stages of extraction equipment delivered globally, our solutions combine automation, modularity, and unmatched corrosion resistance to meet rigorous demands.

Micro Isotope Extraction System Description

Our micro isotope extraction system is designed for laboratories and industrial facilities requiring compact, customizable isotope separation. Ideal for low-volume processing, it ensures high extraction rates, leak-free operation, and adaptability to diverse workflows.

Specifications

| Parameter | Details |

|---|---|

| Mixing Volume | 20ml, 25ml, 50ml, 80ml, 100ml, 125ml (Customizable) |

| Wall Thickness | 8mm, 10mm, 12mm |

| Material Options | PMMA, PTFE, PEEK, Titanium |

| Production Process | CNC Integral Forming |

| Matching Equipment | Optional Micro Injection Pump |

| Agitator Speed | Adjustable (0-500 RPM) |

| Stage Configuration | Modular Design for Flexible Expansion |

Why Choose Our Micro Isotope Extraction System?

- Automation & Precision: Integrated sensors (pH, temperature, liquid level) enable real-time monitoring for consistent results.

- Zero-Leak Guarantee: Proprietary anti-bubbling technology and one-step tank filling/emptying simplify operation.

- Energy Efficiency: Modular components reduce power consumption by 30% compared to traditional systems.

- Rapid Deployment: Pre-assembled units install in <2 hours, with scalability for multi-stage processes.

- Compliance Ready: Meets IAEA safety guidelines, ISO 9001, and CE standards.

Material & Processing Method

Crafted from PTFE, PEEK, or Titanium, our extraction chambers resist corrosive solvents (e.g., TBP, D2EHPA) common in nuclear and medical workflows. CNC machining ensures micron-level accuracy, while 12mm reinforced walls withstand 10+ bar pressure.

How It Works

- Mixing Phase: Adjustable agitators blend organic/aqueous phases at controlled speeds.

- Separation Phase: Gravity-driven settling ensures perfect phase separation in <5 minutes.

- Output: Purified isotopes collect in designated outlets, ready for downstream processing.

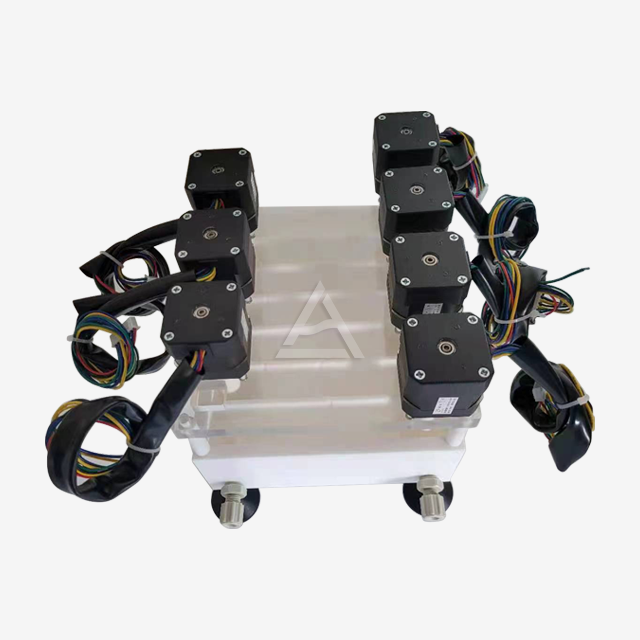

Physical Display

These are not renderings—each micro isotope extraction system shown is real. Use the images to get a true feel for the size, shape, and build. We’re always here to help with more information.

User Guide

- Step 1: Connect the micro injection pump (optional).

- Step 2: Set agitator speed via digital interface.

- Step 3: Monitor extraction efficiency via integrated sensors.

- Step 4: Drain phases via one-touch valves.

Applications

- Nuclear: Isotope separation (U - 235, Pu - 239), spent fuel recycling

In the nuclear field, isotope separation is a complex but essential process. For U - 235, techniques like gas centrifuge separation are used to enrich it from natural uranium, which is crucial for nuclear power generation and some weapons applications. Separating Pu - 239 from other plutonium isotopes is equally challenging and important, often involving chemical separation methods in reprocessing plants. Spent fuel recycling then comes into play. Spent fuel still contains valuable fissile materials. Through a series of chemical and physical processes, these materials can be recovered, reducing the volume of radioactive waste and providing a source of reusable nuclear fuel. - Medical: Radioactive drug synthesis (Tc - 99m, Lu - 177)

Medical radioactive drug synthesis is at the forefront of modern diagnostic and therapeutic medicine. Tc - 99m, a widely used diagnostic radioisotope, is synthesized by eluting molybdenum - 99 from a generator. This technetium - 99m is then combined with various ligands to create radiopharmaceuticals for imaging procedures such as SPECT scans. Lu - 177, on the other hand, is used in targeted radionuclide therapy. It is synthesized by bombarding lutetium - 176 with neutrons in a reactor. The resulting Lu - 177 is conjugated with specific molecules that can target cancer cells, delivering radiation directly to the tumor site for effective treatment. - Environmental: Rare earth recovery from e - waste

With the growing volume of e - waste, rare earth recovery has become an environmentally and economically significant endeavor. E - waste, such as old smartphones and computer monitors, contains small amounts of rare earth elements like neodymium, dysprosium, and terbium. Recovery processes start with dismantling the e - waste to separate components. Then, chemical leaching is used to dissolve the rare earths from the materials. Advanced separation techniques like solvent extraction and ion - exchange chromatography are applied to isolate and purify these elements. Recovering rare earths from e - waste reduces the need for new mining, conserving natural resources and minimizing environmental impact. - Research: Isotope labeling, solvent extraction studies

In research, isotope labeling is a powerful tool. Scientists use isotopically labeled compounds, where a normal atom is replaced with a stable or radioactive isotope. For example, in biological research, carbon - 14 - labeled glucose can be used to trace metabolic pathways. Solvent extraction studies are also prevalent. Researchers explore different solvents and extraction conditions to selectively separate and purify substances. This could involve separating valuable metals from ores or isolating specific organic compounds. These studies contribute to advancements in fields like materials science, environmental analysis, and pharmaceutical development.

Packaging & Transportation

Crush-proof foam packaging with climate-controlled logistics.

After-Sales Service

12-month warranty + lifetime technical support.

Qualification Certification

ISO 9001, CE, IAEA-compliant safety protocols.

FAQs

Q: Can this system handle radioactive materials?

A: Yes – Titanium/PEEK models are radiation-shielded.

Q: Is customization available for specific isotopes?

A: Absolutely. Share your requirements (e.g., phase density, solvent type) for tailored designs.

Q: What's the lead time?

A: 4-6 weeks for standard units; 8 weeks for custom orders.

Q: How do I clean the chambers?

A: Use 5% HNO3 solution; full instructions included.

Q: Do you provide on-site training?

A: Yes – Global technicians available for setup and SOP training.

Contact Us

Need a micro isotope extraction system that scales with your needs?

📩 Email: wangzhijun@cuiyan-tec.com