Pilot Extraction System

Configuration:mobile platform edition, skid mounted edition

Mixing volumn: 8L,10L,20L,40L,60L,80L or customized

Plate thickness:8mm,10mm,12mm,15mm

Material: PP,PPH,PVC,transparent PVC,PMMA

Production process: welding,bonding

Optional function: temperature control device, pH adjustment device, anti-overflow tank device,watch window device

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable mixer-settler stage amount, adjustable agitator speed, and adjustable phase interface height;Highly customizable

Application:rare earth extraction;nickel cobalt extraction;rubidium cesium extraction;salt lake brine extraction;nuclear extraction;vanadium battery recycling;copper electroplate recycling;biological wastewater recycling

- Product Description

Shaanxi Cuiyan: Your Trusted Pilot Extraction System Manufacturer & Supplier

Established in 2012, Shaanxi Cuiyan Technology Co., Ltd is a leading manufacturer of pilot extraction systems, specializing in automated, modular, and corrosion-resistant solutions. With 37+ experts, 9 patented technologies, and 10,000+ equipment stages delivered globally, we empower industries to achieve precise separation, energy efficiency, and scalable workflows.

Pilot Extraction System Specifications

| Specifications | Details |

|---|---|

| Configuration | Mobile Platform Edition / Skid-Mounted Edition |

| Mixing Volume | 8L, 10L, 20L, 40L, 60L, 80L (Customizable) |

| Plate Thickness | 8mm, 10mm, 12mm, 15mm |

| Material | PP, PPH, PVC, Transparent PVC, PMMA |

| Production Process | Welding, Bonding |

| Optional Functions | Temperature Control, pH Adjustment, Anti-Overflow Tank, Watch Window |

Why Choose Our Pilot Extraction System?

- Automation & Precision: Integrated IoT sensors for real-time monitoring (temperature, pH, liquid level).

- Modular Flexibility: Rapid installation, disassembly, and expansion for multi-stage processes.

- Corrosion Resistance: High-grade materials ensure durability in aggressive chemical environments.

- Energy Efficiency: 30% lower energy consumption vs. conventional systems.

- Customization: Tailored mixing/clarification tanks, sensor integration, and process scalability.

Material & Processing Excellence

- Robust Materials: PP and PPH for chemical resistance; transparent PVC/PMMA for real-time observation.

- Advanced Fabrication: CNC welding and bonding techniques ensure leak-proof, long-lasting performance.

Key Functions

- Process Control: Adjust agitator speed (0–500 RPM) and phase interface height.

- Safety Features: Anti-overflow tanks, bubble prevention, and one-step tank emptying.

- Smart Add-Ons: Optional watch windows, temperature/pH modules, and automated data logging.

How It Works

- Mixing Stage: Agitators blend phases thoroughly for optimal extraction.

- Settling Stage: Enhanced baffles accelerate phase separation.

- Adjustability: Fine-tune retention time and flow rates via user-friendly controls.

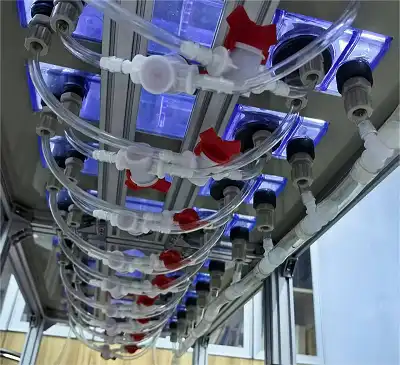

Physical display

All displayed pilot extraction system is real items from our facility. View the high-definition photos for a better understanding. Our support team is available for your questions.

User Guide

- Setup: Mount on leveled surfaces, connect utilities (power, feed lines).

- Operation: Select phase ratios, set agitation speed, and monitor via sensors.

- Maintenance: Clean with mild solvents; inspect seals monthly.

Applications

- Mining & Metals: Rare earth, nickel-cobalt, rubidium-cesium extraction.

- Energy & Recycling: Vanadium battery, copper electroplating, lithium brine processing.

- Environmental: Nuclear waste treatment, biological wastewater recovery.

- Pharmaceuticals: Active ingredient isolation, solvent recovery.

Packaging & Transportation

Our packaging and transportation approach is centered around safeguarding your valuable items. We utilize sturdy wooden crates, crafted from high - quality timber that can endure rough handling during transit. Inside these crates, shock - absorbent padding, such as thick foam inserts or air - filled cushions, is carefully arranged. This padding acts as a protective buffer, effectively reducing the impact of jolts, drops, and vibrations. Whether it's delicate electronics, precision machinery, or high - value products, our packaging ensures they reach their destination in pristine condition, minimizing the risk of damage.

After - Sales Service

We pride ourselves on delivering comprehensive after - sales support. With 24/7 technical support, our team of experienced technicians is always on standby to assist you. Day or night, you can reach out for help with product - related queries, troubleshooting, or operational guidance. Additionally, we offer a 2 - year warranty, providing you with peace of mind. If any defects or malfunctions occur within this period, we will repair or replace the product at no extra cost. We also ensure easy access to spare parts, enabling quick and efficient maintenance to keep your product running smoothly.

Certifications

Our commitment to quality and innovation is evident through our impressive range of certifications. ISO 9001 attests to our robust quality management system, ensuring consistent product excellence. Holding 8+ national patents showcases our dedication to research and development, resulting in unique and improved solutions. CE compliance indicates that our products meet strict European health, safety, and environmental protection standards. These certifications not only reflect our high - standard manufacturing processes but also instill confidence in our customers, both domestically and globally.

FAQ

Q1: Can this system handle high-viscosity fluids?

A1: Yes! Our adjustable agitators and wide-diameter inlets manage viscosities up to 5,000 cP.

Q2: What's the lead time for custom configurations?

A2: 4–6 weeks post-design approval, depending on complexity.

Q3: Do you provide onsite installation support?

A3: Global technicians assist with setup, calibration, and training.

Q4: Are your materials FDA-compliant for food/pharma use?

A4: PP and PMMA options meet FDA, USP Class VI, and EU 10/2011 standards.

Q5: How energy-efficient is this system?

A5: Variable-speed drives reduce power consumption by 30% vs. fixed-speed models.

Contact Us

Optimize your extraction process with Xi'an Plansee's pilot extraction system – engineered for reliability and innovation.

📩 Email: wangzhijun@cuiyan-tec.com