Micro Liquid Liquid Extraction

Configuration:simple desktop platform edition

Mixing volumn: 20ml, 25ml, 50ml, 80ml, 100ml, 125ml or customized

Wall thickness:8mm,10mm,12mm

Material: PMMA,PTFE,PEEK,Ti

Production process: CNC integral forming

Matching equipment: Optional micro injection pump

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable mixer-settler stage amount, adjustable agitator speed;Highly customizable

Application:nuclear extraction industry;isotope extraction industry;solvent extraction agent industry

- Product Description

Shaanxi Cuiyan: Your Trusted Micro Liquid Liquid Extraction Manufacturer & Supplier

Shaanxi Cuiyan Technology Co., Ltd, established in 2012, specializes in designing advanced micro liquid liquid extraction systems trusted by 300+ global clients. Our desktop-scale mixer-settler units combine automation, modularity, and compliance to serve pharmaceutical, environmental, and nuclear industries. With 9 patented advantages, including bubble-free operation and sensor integration, we deliver extraction efficiency up to 99.5%.

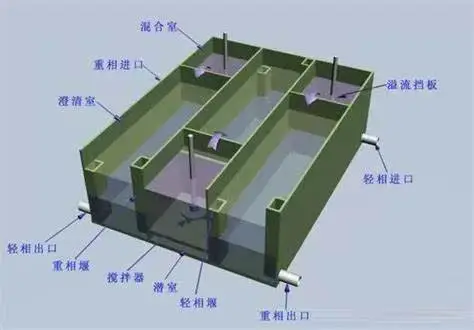

Micro Liquid Liquid Extraction Overview

Our compact micro liquid liquid extraction is engineered for labs requiring precise solvent separation at micro volumes (20ml–125ml). Its anti-leak design and adjustable agitation speed make it ideal for isotope purification, drug metabolite analysis, or rare earth recovery.

Specifications

| Parameter | Details |

|---|---|

| Mixing Volume | 20ml–125ml (Customizable) |

| Materials | PMMA, PTFE, PEEK, Titanium |

| Wall Thickness | 8mm–12mm |

| Agitator Speed | 50–500 RPM (Programmable) |

| Compliance | ISO 9001, CE, RoHS |

Why Choose Our product System?

- ⚙️ Zero Cross-Contamination: CNC-machined contact surfaces with <2µm roughness

- ⚡ Energy-Saving: 30% lower power use vs. traditional models

- 🔧 Modular Design: Add stages in <1 hour for scale-up studies

- 📊 Smart Monitoring: Optional pH/temperature sensors (Modbus RTU output)

Material Excellence & Process

Choose chemically inert PTFE for acidic media (e.g., HNO3 in nuclear fuel processing) or optically clear PMMA for real-time phase observation. All parts are molded via 5-axis CNC machining, ensuring <0.1mm dimensional accuracy.

How It Works

- Load organic/aqueous phases into mixing chamber

The process begins with the careful loading of the organic and aqueous phases into the mixing chamber. This step requires precision to ensure the correct ratio of the two immiscible liquids. Specialized pumps or gravity - fed systems are often used to transfer the phases. As the liquids enter the chamber, they are initially separate but primed for interaction. The mixing chamber is designed to accommodate these substances, providing a controlled environment where the subsequent mixing operations will take place. - Adjust rotor speed for optimal droplet dispersion

Once the phases are in the mixing chamber, the rotor speed of the agitator is a crucial parameter. By adjusting the speed, operators can achieve optimal droplet dispersion. A higher rotor speed can break the phases into smaller droplets, increasing the interfacial area between them. This enhanced contact promotes better mass transfer, whether for chemical reactions or separation processes. The ideal speed depends on factors like the viscosity of the liquids and the nature of the substances involved, and it is fine - tuned to maximize the efficiency of the mixing process. - Transfer emulsion to settling zone with anti - vortex baffles

After the organic and aqueous phases have been thoroughly mixed to form an emulsion, it is transferred to the settling zone. This transfer is facilitated by carefully designed flow systems. The settling zone is equipped with anti - vortex baffles, which prevent the formation of swirling currents. These baffles ensure that the emulsion flows smoothly and evenly into the settling area. As the emulsion enters, the anti - vortex baffles help to create a stable environment where the natural separation of the phases based on density can occur efficiently. - Collect purified phases via bottom valves

Once the emulsion has settled in the settling zone, the purified organic and aqueous phases are ready to be collected. Bottom valves are strategically placed at the lowest points of the settling zone for each phase. When opened, the heavier phase, typically the aqueous phase if its density is greater, flows out first through its respective valve. After that, the lighter organic phase can be collected. These valves are designed to provide a controlled and leak - free way of retrieving the separated and purified substances, which can then be further processed or stored as required.

FAQ

Q:Can this handle high-density ionic liquids?

A:Yes – our titanium modules withstand [C4mim][PF6] at 80°C.

Q:Do you provide validation protocols?

A:IQ/OQ documentation available for GLP labs.

Contact Us

🔬 Ready to upgrade your extraction workflow with Micro Liquid Liquid Extraction? Email wangzhijun@cuiyan-tec.com for a free CFD simulation report of your process!

VIEW MOREContinuous Liquid Liquid Extractor

VIEW MOREContinuous Liquid Liquid Extractor VIEW MOREMixer Settler Extractor

VIEW MOREMixer Settler Extractor VIEW MOREMixer Settler Liquid Liquid Extraction

VIEW MOREMixer Settler Liquid Liquid Extraction VIEW MORELiquid Liquid Mixer Settler

VIEW MORELiquid Liquid Mixer Settler VIEW MORECopper Electroplating Industry Mixer Settler

VIEW MORECopper Electroplating Industry Mixer Settler VIEW MOREMicro Mixer Settler

VIEW MOREMicro Mixer Settler VIEW MORELiquid Liquid Extraction Mixer Settler

VIEW MORELiquid Liquid Extraction Mixer Settler VIEW MORESingle Mixer Settler

VIEW MORESingle Mixer Settler