Copper Electroplating Industry Mixer Settler

Cooperation solution: labor+material contracting,labor-ony contracting

Mixing volumn: 100L,200L,300L,500L,800L,1000L or customized

Plate thickness:12mm,15mm,20mm,25mm,30mm

Material: PP,PPH,PVC,transparent PVC

Production process: welding

Optional function: temperature control device,pH adjustment device,anti-overflow tank device

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable agitator speed,adjustable phase interface height

Application: rare earth extraction;nickel cobalt extraction;rubidium cesium extraction;salt lake brine extraction;nuclear extraction;lithium battery recycling;vanadium battery recycling;copper electroplate recycling;biological wastewater recycling

- Product Description

Shaanxi Cuiyan: Your Trusted Copper Electroplating Industry Mixer Settler Manufacturer & Supplier

Since 2012, Shaanxi Cuiyan Technology Co., Ltd has specialized in designing copper electroplating industry mixer settlers that combine cutting-edge automation, modularity, and corrosion resistance. With 37+ experts and 9 patented advantages—including anti-bubbling technology, energy-saving designs, and scalable solutions—we've delivered 10,000+ stages of equipment to 300+ global clients.

Copper Electroplating Industry Mixer Settler Description

Our copper electroplating industry mixer settler optimizes metal recovery and wastewater treatment through precision engineering. Ideal for electrolytic purification, PCB manufacturing, and industrial recycling, it ensures high extraction rates, leak-proof operation, and compliance with global environmental standards.

Specifications

| Parameter | Details |

|---|---|

| Mixing Volume | 100L–1000L (Customizable) |

| Plate Thickness | 12mm–30mm (PP, PPH, PVC, Transparent PVC) |

| Production Process | Welding |

| Optional Functions | Temperature/pH Control, Anti-Overflow Device |

| Key Advantages | 98% Extraction Rate, Adjustable Agitator Speed, Modular Expansion |

Why Choose Our Copper Electroplating Mixer Settler?

- Corrosion-Resistant Materials: PP/PPH/PVC construction withstands acidic/alkaline environments.

- Automation Ready: Integrate sensors (pH, temperature) or PLC systems for 24/7 monitoring.

- Scalable Design: Add modules to expand capacity without downtime.

- Energy Efficiency: 30% lower能耗 vs. conventional models.

Material & Processing Method

- Body Material: High-density PP/PPH for durability; transparent PVC for real-time observation.

- Welding Technique: Laser-welded seams prevent leaks, even under high-pressure operations.

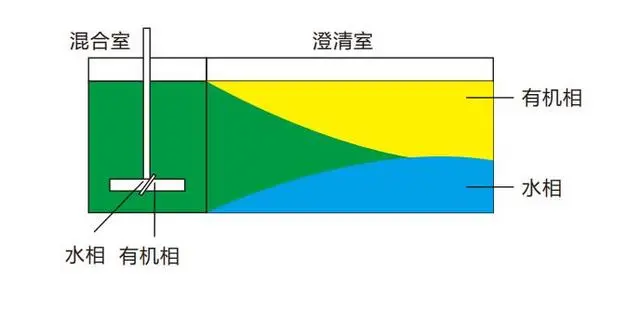

How It Works

- Mixing Phase: Adjustable impellers blend solutions uniformly, maximizing metal-ion contact.

- Settling Phase: Laminar flow design accelerates phase separation, reducing processing time by 20%.

- Output: Purified electrolyte flows to storage, while extracted metals are collected for reuse.

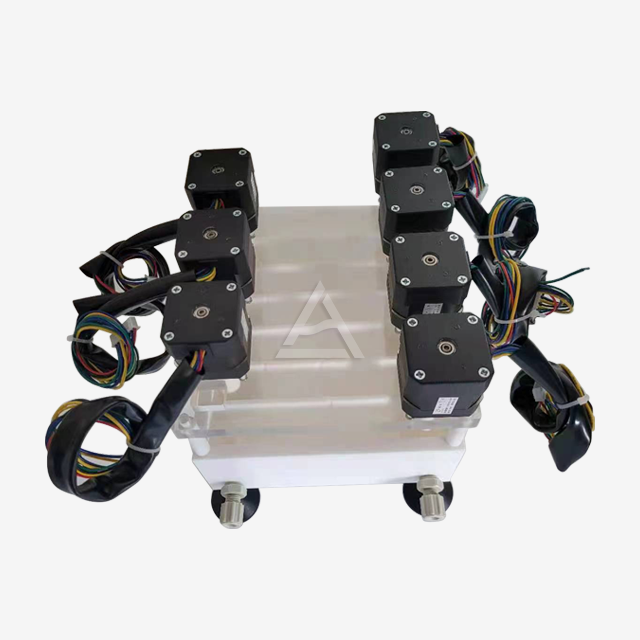

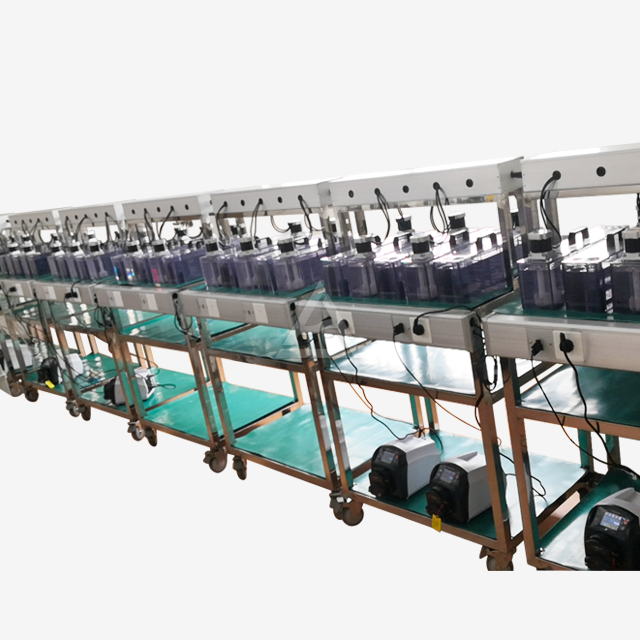

Physical Display

View our real copper electroplating industry mixer settler displays online. High-quality images give you a clear sense of structure and function. Our team is available for any inquiries.

User Guide

- Installation: Bolt-on modules enable setup in <48 hours.

- Maintenance: Self-cleaning nozzles and removable panels simplify upkeep.

Applications

- Electrolytic copper purification

Electrolytic copper purification is a crucial process in the copper industry. Impure copper anodes are placed in an electrolytic cell filled with a copper sulfate solution. When an electric current is applied, copper atoms from the anode dissolve into the solution as copper ions. Pure copper then deposits onto the cathode. Impurities either remain in solution or form a sludge at the bottom of the cell. This method can achieve high - purity copper, essential for applications in electronics, where its excellent electrical conductivity is highly valued. The process is energy - intensive but offers a reliable way to obtain copper suitable for making wires, printed circuit boards, and other high - tech components. - PCB/electronic plating wastewater treatment

PCB (Printed Circuit Board) and electronic plating wastewater contains a complex mix of heavy metals like copper, nickel, and lead, along with toxic organic compounds. Treatment begins with physical processes such as filtration to remove large particles. Chemical precipitation follows, where chemicals are added to form insoluble metal compounds that can be separated. Advanced techniques like ion - exchange resins are used to capture remaining metal ions. Biological treatment may also be employed to break down organic contaminants. Proper treatment of this wastewater is essential to prevent environmental pollution and to meet strict regulatory standards, as the release of these harmful substances can have severe impacts on aquatic life and human health. - Lithium/vanadium battery recycling

With the growing use of lithium - ion and vanadium - based batteries, recycling has become imperative. The process starts with mechanical dismantling of spent batteries to separate components. Chemical leaching is then used to dissolve lithium and vanadium from the battery materials. Precipitation and solvent extraction methods are employed to isolate and purify these metals. The recovered lithium and vanadium can be reused in new battery manufacturing, reducing the need for virgin mining. This not only conserves natural resources but also decreases the environmental footprint associated with battery production and disposal. - Rare earth & salt - lake brine extraction

Rare earth extraction from salt - lake brines is a unique and increasingly important process. First, the brine is pumped to the surface. Specialized chemical reagents are added to selectively bind with rare earth elements present in the brine. Solvent extraction techniques are then used to separate the rare earth - containing compounds from the rest of the brine components. Multiple extraction and purification steps follow to obtain high - purity rare earths. These elements, crucial for applications in electronics, clean energy, and defense, are in high demand. Salt - lake brines offer a significant source, especially as traditional ore - based extraction faces challenges in terms of environmental impact and resource availability.

Packaging & Transportation

Crush-proof wooden cases with moisture barriers ensure safe global delivery.

After-Sales Service

24/7 remote troubleshooting, onsite training, and a 5-year warranty.

Qualification Certification

ISO 9001, CE, and RoHS-compliant.

FAQ

Q: Can you customize mixer settlers for high-salinity wastewater?

A: Yes! We've built 50+ systems for salt-lake lithium extraction with pH sensors and titanium coatings.

Q: What's the lead time for a 500L model?

A: 3–4 weeks, including factory testing.

Q: Do you provide automation integration?

A: Absolutely—we partner with Siemens/ABB for PLC and IoT solutions.

Q: How does your design prevent leaks?

A: Multi-layer welding + pressure testing at 1.5x operational limits.

Q: Are your materials REACH-compliant?

A: Yes—all polymers meet EU/US chemical safety standards.

Contact Us

Elevate your copper electroplating efficiency with a copper electroplating industry mixer settler built for precision and scale. Email [wangzhijun@cuiyan-tec.com] for a free consultation or tailored quote!