Liquid Liquid Extraction Mixer Settler

Configuration:desktop base edition, mobile standard edition, environmentally friendly high edition

Mixing volumn: 200ml, 300ml, 500ml, 1L, 2L, 3L or customized

Plate thickness:5mm,6mm,8mm,10mm

Material: PP,PPH,PVC,transparent PVC,PMMA,PTFE,PEEK,SUS,Ti

Production process: welding,bonding,bending,injection molding,integral forming

Optional function: temperature control device, pH adjustment device, water-bath jacket device, anti-overflow tank device,watch window device

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable mixer-settler stage amount, adjustable agitator speed, and adjustable phase interface height;Highly customizable

Application:rare earth extraction;nickel cobalt extraction;rubidium cesium extraction;salt lake brine extraction;nuclear extraction;isotope extraction;lithium battery recycling;vanadium battery recycling;copper electroplate recycling;biological wastewater recycling

- Product Description

Shaanxi Cuiyan: Your Trusted Liquid Liquid Extraction Mixer Settler Manufacturer & Supplier

Shaanxi Cuiyan Technology Co., Ltd – Your trusted liquid liquid extraction mixer settler manufacturer & supplier since 2012. With 37+ experts and 9+ patented technologies, we deliver lab to industrial-scale solutions featuring automation, modularity, and energy efficiency. Our equipment excels in corrosion resistance, customizable designs, and seamless integration with sensors for superior extraction performance.

Liquid Liquid Extraction Mixer Settler Description

Our liquid liquid extraction mixer settler is engineered for precise phase separation in industries like metallurgy, pharmaceuticals, and environmental protection. Designed for flexibility, it supports adjustable mixing speeds, stage configurations, and material compatibility to meet diverse process requirements.

Specifications

| Parameter | Options |

|---|---|

| Configuration | Desktop Base Edition, Mobile Standard Edition, Environmentally High Edition |

| Mixing Volume | 200ml, 300ml, 500ml, 1L, 2L, 3L (Customizable) |

| Plate Thickness | 5mm, 6mm, 8mm, 10mm |

| Material | PP, PPH, PVC, Transparent PVC, PMMA, PTFE, SUS, Ti |

| Production Process | Welding, Bonding, Bending, Injection Molding, Integral Forming |

| Optional Functions | Temperature Control, pH Adjustment, Anti-Overflow Tank, Watch Window |

Why Choose Our Mixer Settler?

- Customization: Tailor mixing stages, materials, and sensors (pH, temperature) to your needs.

- Efficiency: Achieve 95%+ extraction rates with optimized phase separation.

- Durability: Corrosion-resistant materials ensure 10+ years of service life.

- Energy Savings: Modular design reduces solvent loss by 20%.

- Technical Support: 24/7 engineering assistance for seamless integration.

Material & Processing Methods

We use PP, PTFE, or titanium for aggressive media (acids, alkalis) and transparent PVC/PMMA for real-time observation. Advanced processes like integral forming eliminate leakage risks.

Key Functions

- Anti-bubbling design for stable mixing.

- Adjustable mixer speed (50-500 RPM) and phase interface height.

- Integrated sensors for automated control.

- One-step tank filling/emptying to minimize downtime.

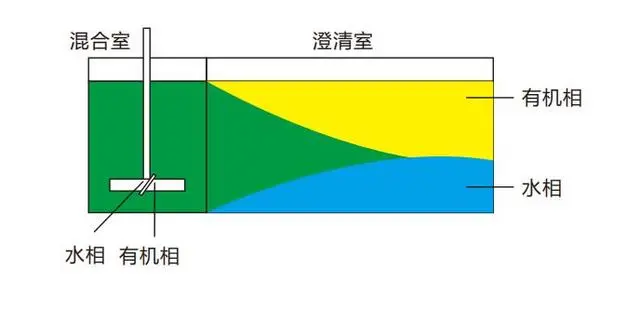

How It Works

- Mixing Phase: The two liquid phases are agitated to transfer target components.

- Settling Phase: Immiscible liquids separate naturally in the settler chamber.

- Collection: Purified streams are discharged via dedicated outlets.

Applications

- Metals: Rare earth, cobalt, lithium, and copper extraction.

- Chemicals: Solvent recovery, catalyst separation.

- Environmental: Heavy metal removal, battery recycling.

- Pharma: Antibiotic purification, natural product extraction.

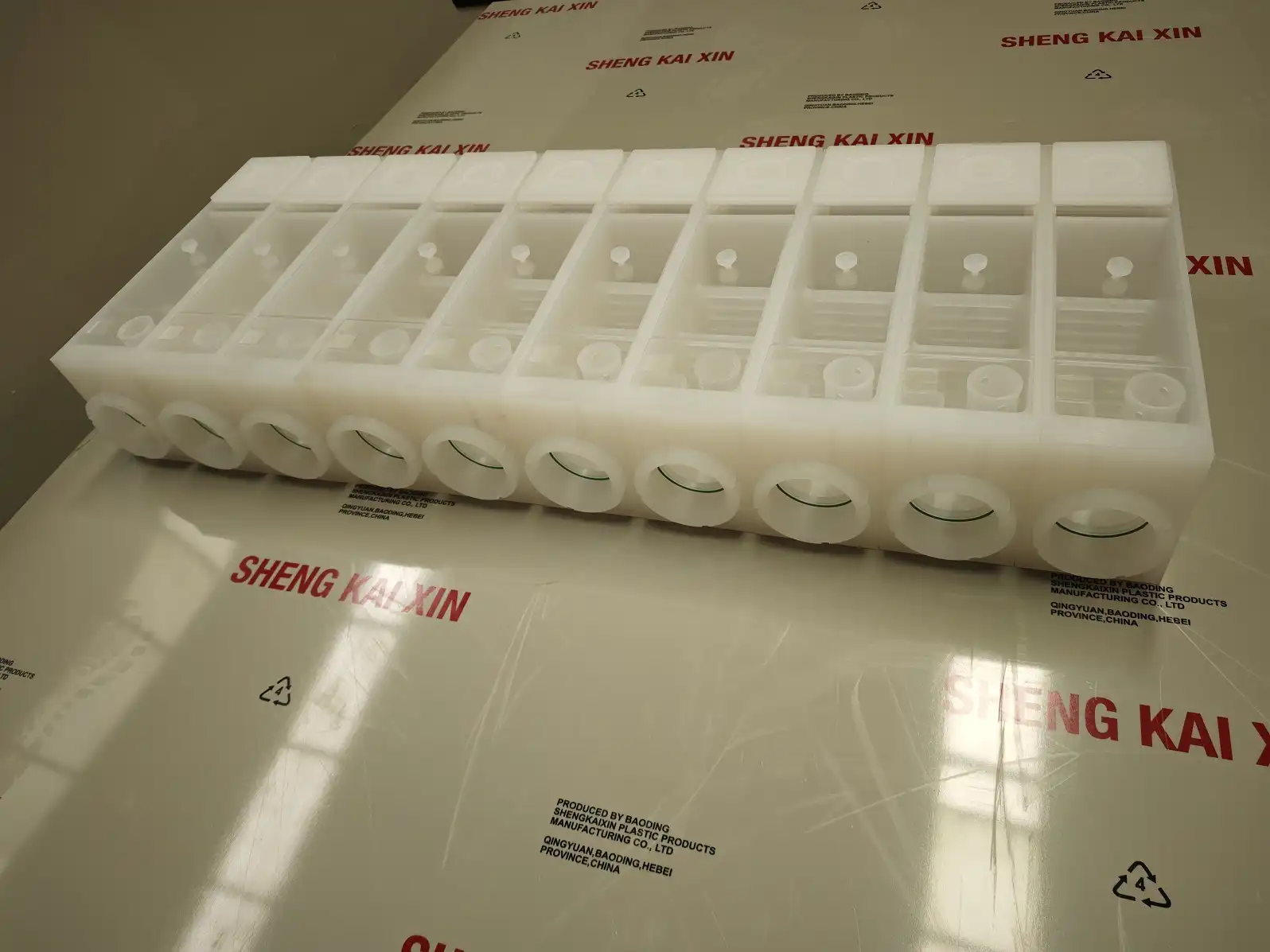

Physical Display

What you see here are actual Liquid Liquid Extraction Mixer Settler displays. Our photos are meant to give you an honest view of our equipment in real conditions.

User Guide

- Install the equipment on a stable surface

Selecting an appropriate and stable surface for equipment installation is the foundation for its proper functioning. The surface should be flat, free from vibrations, and capable of bearing the weight of the equipment. Use levelling tools to ensure the equipment is perfectly horizontal. Secure the equipment to the surface using bolts or clamps if necessary. This prevents any movement during operation that could disrupt the delicate separation processes it is designed to perform, guaranteeing consistent and accurate results. - Connect sensors and power supply

After installation, carefully connect the sensors to the equipment. These sensors are crucial for monitoring various parameters such as temperature, pressure, and flow rate during the separation process. Ensure all sensor cables are properly inserted and fastened to avoid disconnections. Then, connect the power supply, making sure to follow safety protocols. Check the voltage requirements of the equipment and match it with the power source. A stable power connection is essential for the continuous operation of the equipment and the accurate readings of the sensors. - Set parameters via the control panel

The control panel is the interface through which you can customize the operation of the equipment. Navigate the user - friendly menu to set parameters like separation time, speed of agitators (if applicable), and target purity levels. Each parameter is adjustable according to the specific needs of the separation task at hand. For example, if separating a more viscous mixture, you might increase the agitation speed. Input the values precisely to optimize the separation process and achieve the desired outcome efficiently. - Monitor separation via the watch window

The watch window provides a direct visual means of monitoring the separation process. Observe the movement and behavior of the substances within the equipment. Notice how different phases separate over time, looking for any signs of incomplete separation or abnormal flow patterns. If the separation seems to be taking longer than expected or if there are irregularities in the way the substances are dividing, it could indicate a problem with the equipment or the set parameters. Regular monitoring via the watch window allows for timely adjustments to ensure a successful separation.

Packaging & Transportation

Shockproof wooden crates ensure safe global delivery.

After-Sales Service

Lifetime maintenance support with 72-hour response guarantee.

Certifications

ISO 9001, CE, 10+ patents in extraction technology.

FAQ

Q: Can I customize the mixer settler for high-temperature processes?

A: Yes! We offer SUS316 or titanium materials for up to 200°C.

Q: Are your products certified?

A: All equipment meets ISO 9001, CE, and RoHS standards.

Q: What's the lead time?

A: 4-6 weeks for standard models; 8-10 weeks for customized orders.

Q: Do you provide technical training?

A: Yes – free on-site training included with every purchase.

Q: What's the warranty period?

A: 2 years for mechanical parts, 1 year for electronic components.

Contact Us

Ready to optimize your extraction process? Email wangzhijun@cuiyan-tec.com for a quote or technical consultation of Liquid Liquid Extraction Mixer Settler.