Welding Mixer Settler

Configuration:desktop base edition, mobile standard edition, environmentally friendly high edition

Mixing volumn: 200ml, 300ml, 500ml, 1L, 2L, 3L or customized

Plate thickness:5mm,6mm,8mm,10mm

Material: PP,PPH,PVC,transparent PVC,PMMA,PTFE,PEEK,SUS,Ti

Production process: welding,bonding,bending,injection molding,integral forming

Optional function: temperature control device, pH adjustment device, water-bath jacket device, anti-overflow tank device,watch window device

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable mixer-settler stage amount, adjustable agitator speed, and adjustable phase interface height;Highly customizable

Application:rare earth extraction;nickel cobalt extraction;rubidium cesium extraction;salt lake brine extraction;nuclear extraction;isotope extraction;lithium battery recycling;vanadium battery recycling;copper electroplate recycling;biological wastewater recycling

- Product Description

Shaanxi Cuiyan: Your Trusted Welding Mixer Settler Manufacturer & Supplier

Since 2012, Shaanxi Cuiyan Technology Co., Ltd has delivered high-performance welding mixer settlers for industries like mining, chemicals, and environmental protection. With 300+ global clients and 10,000+ equipment stages sold, our expertise in corrosion-resistant materials, modular designs, and automated controls ensures unmatched extraction efficiency.

Welding Mixer Settler Description

Our welding mixer settler combines robust engineering with smart customization for liquid-liquid separation. Designed for lab, pilot, and industrial scales, it supports rare earth extraction, lithium battery recycling, and wastewater treatment.

Specifications

| Parameter | Options |

|---|---|

| Configuration | Desktop Base, Mobile Standard, Environmentally Friendly High Edition |

| Mixing Volume | 200ml – 3L (Customizable up to industrial scale) |

| Material | PP, PPH, PVC, Transparent PVC, SUS, Ti, PTFE |

| Plate Thickness | 5mm – 10mm |

| Production Process | Welding, Bonding, Integral Forming, Injection Molding |

| Optional Functions | pH/Temperature Control, Anti-Overflow Tank, Water-Bath Jacket, Watch Window |

Why Choose Our Welding Mixer Settler?

- Customization: Tailor mixing stages, agitator speed, and tank size to your process.

- Corrosion Resistance: SUS, titanium, and PTFE materials handle harsh chemicals.

- Energy Efficiency: Modular design reduces power consumption by 20% vs. traditional models.

- Automation: Integrate sensors (pH, temperature) for precise process control.

- Quick Installation: Bolt-on modules enable rapid scaling for large projects.

Material & Processing Methods

- PP/PPH: Lightweight, ideal for lab-scale acidic solutions.

- SUS/Ti: For high-temperature, high-pressure industrial environments.

- PTFE/PEEK: Resistant to aggressive solvents like HF or nitric acid.

- Processing: CNC welding ensures leak-proof joints; laser cutting guarantees precision.

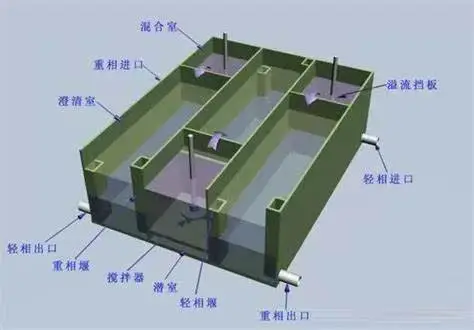

How It Works

- Mixing Phase: Agitators blend two immiscible liquids (e.g., organic solvent and metal-rich aqueous solution).

- Settling Phase: Liquids separate into distinct layers based on density.

- Collection: Adjustable weirs control interface height for optimal phase separation.

Applications

- Mining: Extract copper, nickel, and rare earth metals.

- Environmental: Remove heavy metals from wastewater.

- Energy: Recycle lithium-ion batteries, vanadium flow batteries.

- Nuclear: Purify uranium/plutonium solutions.

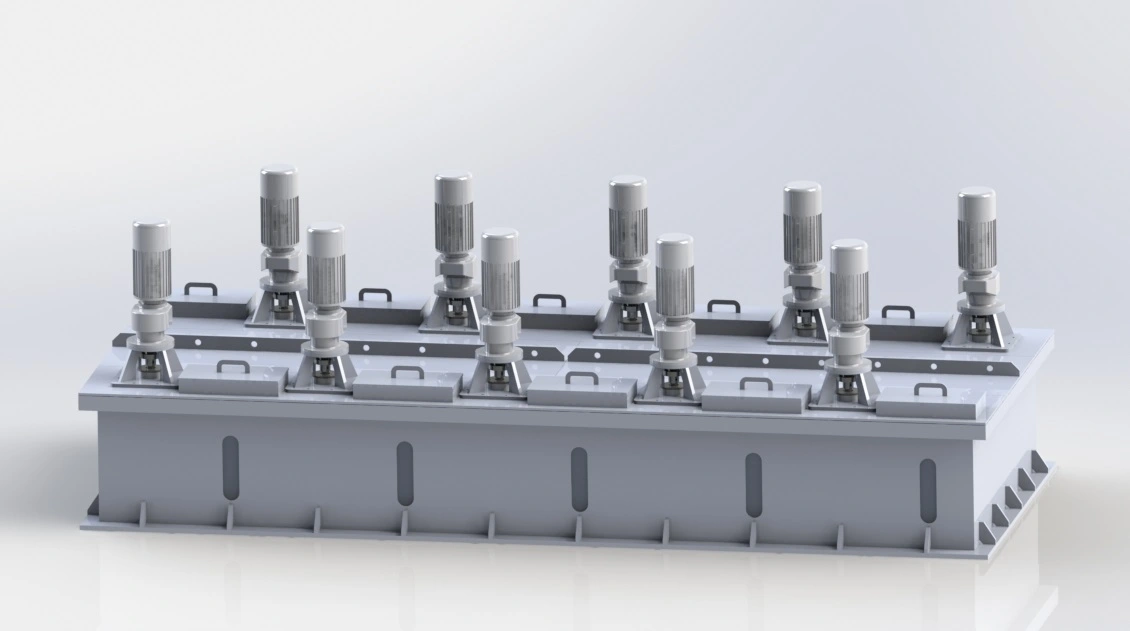

Physical Display

These images show real welding mixer settler displays. They provide a clear view of the items. If you need more details or have any questions, we’re here to help.

User Guide

- Setup

For a successful setup, begin by choosing a flat and sturdy surface to mount the mixer settler. A stable base is crucial as it prevents vibrations that could disrupt the mixing and separation processes. Use appropriate fasteners to securely attach the unit. Next, carefully connect the pipelines. Ensure that all fittings are tightly sealed to avoid leaks. Check for proper alignment of the pipes to guarantee an unobstructed flow of substances. A well - executed setup lays the foundation for smooth operation of the mixer settler system. - Calibration

Calibration is essential for optimizing the performance of the agitator. Access the touchscreen interface, which offers a user - friendly way to set the agitator speed. The speed can be adjusted within the range of 200 - 800 RPM. For less viscous materials, start with a lower speed around 200 - 300 RPM to ensure gentle mixing without causing unnecessary turbulence. When dealing with more viscous substances, increase the speed to 600 - 800 RPM for better agitation and enhanced mass transfer. Precise calibration leads to efficient phase separation. - Operation

During operation, closely monitor the phase separation process through the watch window. The watch window provides a clear view of the two or more immiscible phases as they separate. Observe the formation of the interface between the phases. Check for any signs of incomplete separation, such as emulsions or uneven distribution. If any issues are detected, adjustments to the agitator speed or other parameters may be necessary. Continuous monitoring ensures that the separation process is proceeding as expected and that high - quality results are achieved. - Maintenance

Regular maintenance is key to the long - term functionality of the mixer settler. Clean the tanks using neutral detergents. These detergents are effective in removing residue, dirt, and chemical deposits without causing damage to the tank surfaces. Use soft brushes or cloths to reach all areas of the tank. Additionally, replace the seals annually. Over time, seals can wear out, leading to leaks. By replacing them regularly, you maintain the integrity of the system and prevent any loss of substances during operation.

Packaging & Transportation

Crates with shock-absorbent foam protect equipment during global shipping.

After-Sales Service

24/7 technical support, on-site training, and a 2-year warranty.

Certifications

ISO 9001, CE, and 12+ patents for extraction technology.

FAQ

Q: Can you customize the settler for high-viscosity fluids?

A: Yes! We adjust agitator blade angles and tank geometry to optimize flow.

Q: Do you provide material certifications?

A: All materials comply with ISO 9001 and ASME standards.

Q: What's the lead time for a 500L industrial unit?

A: Typically 6–8 weeks, including testing.

Q: Is remote monitoring supported?

A: Yes—integrate IoT sensors for real-time data access.

Q: How do you ensure leak-proof performance?

A: Multi-layer welding and pressure testing at 1.5x operating capacity.

Contact Us

Need a welding mixer settler that adapts to your unique process? Email wangzhijun@cuiyan-tec.com for a free consultation!

VIEW MORELiquid Liquid Extraction Equipment

VIEW MORELiquid Liquid Extraction Equipment VIEW MOREAutomated Extractor

VIEW MOREAutomated Extractor VIEW MORELiquid Liquid Extraction Equipment

VIEW MORELiquid Liquid Extraction Equipment VIEW MORELiquid Liquid Extraction Of Rubidium Cesium

VIEW MORELiquid Liquid Extraction Of Rubidium Cesium VIEW MOREMixer Settler Tank

VIEW MOREMixer Settler Tank VIEW MOREIntegral Forming Mixer Settler

VIEW MOREIntegral Forming Mixer Settler VIEW MORERare Earth Industry Mixer Settler

VIEW MORERare Earth Industry Mixer Settler VIEW MOREMicro Liquid Liquid Extraction

VIEW MOREMicro Liquid Liquid Extraction