Integral Forming Mixer Settler

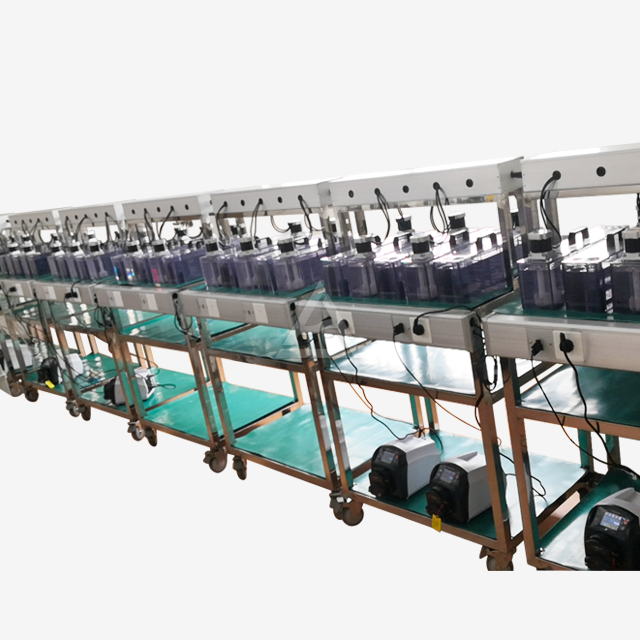

Configuration:desktop base edition, mobile standard edition, environmentally friendly high edition

Mixing volumn: 200ml, 300ml, 500ml, 1L, 2L, 3L or customized

Plate thickness:5mm,6mm,8mm,10mm

Material: PP,PPH,PVC,transparent PVC,PMMA,PTFE,PEEK,SUS,Ti

Production process: welding,bonding,bending,injection molding,integral forming

Optional function: temperature control device, pH adjustment device, water-bath jacket device, anti-overflow tank device,watch window device

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable mixer-settler stage amount, adjustable agitator speed, and adjustable phase interface height;Highly customizable

Application:rare earth extraction;nickel cobalt extraction;rubidium cesium extraction;salt lake brine extraction;nuclear extraction;isotope extraction;lithium battery recycling;vanadium battery recycling;copper electroplate recycling;biological wastewater recycling

- Product Description

Shaanxi Cuiyan: Your Trusted Integral Forming Mixer Settler Manufacturer & Supplier

Established in 2012, Shaanxi Cuiyan Technology specializes in designing integral forming mixer settlers for lab, pilot, and industrial applications. With 300+ global clients and 9,000+ stages delivered, our equipment combines patented modular designs, automation integration, and unmatched corrosion resistance to streamline solvent extraction processes.

Integral Forming Mixer Settler Description

Our integral forming mixer settler optimizes liquid-liquid extraction with leak-proof construction and adaptable configurations. Ideal for rare earth refining, lithium recovery, and nuclear fuel processing, it ensures precise phase separation and scalable throughput.

Specifications

| Specifications | Details |

|---|---|

| Mixing Volume | 200mL – 3L (Customizable) |

| Material Options | PP, PVC, PTFE, SUS, Titanium |

| Plate Thickness | 5mm – 10mm |

| Production Process | Welding, Integral Forming, Injection Molding |

| Optional Features | pH/Temperature Control, Anti-Overflow Tank, Transparent PMMA Observation Window |

Why Choose Our product?

- Patented Modular Design: Rapid installation and scalability for multi-stage extraction systems.

- Automation-Ready: Integrate sensors (pH, temperature) or PLC controls for hands-free operation.

- Corrosion Resistance: Titanium and PTFE options withstand aggressive chemicals in mining or nuclear applications.

- Energy Efficiency: Low power consumption with optimized agitator speed control.

Material & Processing Excellence

- Robust Materials: SUS316L for acidic environments, PTFE for high-purity pharmaceutical extraction.

- Leak-Proof Welding: Laser-welded joints eliminate leakage risks in continuous operations.

- Transparent Options: PMMA or PVC observation windows enable real-time process monitoring.

How It Works

The integral forming mixer settler uses mechanical agitation to mix immiscible liquids (organic/aqueous phases) in the mixing chamber. The emulsion then flows into the settling zone, where gravity separates the phases based on density. Adjustable weirs control interface levels, ensuring consistent extraction rates up to 99.8%.

Key Applications

- Mining & Metallurgy: Rare earth, nickel, cobalt, and rubidium recovery.

- Battery Recycling: Lithium-ion and vanadium flow battery material extraction.

- Nuclear Industry: Uranium/plutonium separation and radioactive wastewater treatment.

- Environmental: Heavy metal removal (copper, zinc) from industrial effluents.

User Guide

- Setup

The setup process begins with carefully selecting a vibration - free surface for mounting the mixer settler. Vibrations can disrupt the delicate mixing and separation processes, so a stable foundation is essential. Use appropriate fasteners to securely fix the unit in place. After that, connect the feed pumps, ensuring a tight seal on all connections to prevent leaks. Then, attach the discharge lines, making sure they are properly aligned for smooth outflow. Double - check all connections and the stability of the mounted unit to guarantee a trouble - free start to the operation. - Calibration

Calibration of the agitator speed is crucial for optimal performance. Utilize the digital controller, which offers a user - friendly interface. You can precisely set the agitator speed within the range of 100 - 600 RPM. For less viscous materials, a lower speed like 100 - 200 RPM might be sufficient for gentle blending, minimizing energy consumption. However, when dealing with more viscous substances or for processes requiring more intense mixing, increase the speed to 400 - 600 RPM. Regular calibration ensures consistent and efficient operation. - Operation

During operation, closely monitor the phase separation through the sight glasses. These glasses provide a clear view of how the immiscible phases are separating. Observe the formation of a distinct interface between the phases. If the separation is not occurring as expected, check and adjust the weirs. The weirs control the flow and level of the liquid phases, and proper adjustment can enhance the separation efficiency. Continuously monitor the process to maintain high - quality separation results. - Maintenance

Regular maintenance is key to the long - term functionality of the mixer settler. Every month, clean the channels using non - abrasive solvents. These solvents are effective in removing residue, scale, and chemical deposits that accumulate over time. Apply the solvent carefully, using brushes or cleaning tools designed for the channels' shape and size. After cleaning, thoroughly rinse the channels to ensure no solvent remains. This maintenance routine helps prevent blockages and keeps the system running smoothly.

Packaging & Transportation

Equipment is crated in shock-resistant frames with desiccant packs for international shipping.

After-Sales Service

24/7 remote diagnostics and a 5-year warranty on integral forming mixer settler components.

Certifications

ISO 9001, CE, and GB/T 19001-2016 certified.

FAQ

Q: Can you customize mixer settlers for high-temperature processes?

A: Yes! We offer titanium or PEEK materials stable up to 200°C.

Q: Do your systems comply with ASME standards?

A: Absolutely. We provide CE, ISO, and ASME-certified designs.

Q: What's the lead time for a 500L/day system?

A: Standard units ship in 4 weeks; custom designs require 6–8 weeks.

Q: Can I upgrade existing equipment with your modules?

A: Yes. Our modular mixers integrate seamlessly with most industrial setups.

Q: Do you offer on-site installation support?

A: Global technical teams assist with commissioning and training.

Contact Us

Ready to enhance your extraction process? Email wangzhijun@cuiyan-tec.com for a free consultation of Integral Forming Mixer Settler.

VIEW MOREAutomated Extractor

VIEW MOREAutomated Extractor VIEW MOREMixer Settler Liquid Liquid Extraction

VIEW MOREMixer Settler Liquid Liquid Extraction VIEW MORELab Scale Mixer Settler

VIEW MORELab Scale Mixer Settler VIEW MOREEnvironmentally Friendly Mixer Settler

VIEW MOREEnvironmentally Friendly Mixer Settler VIEW MORENickel Cobalt Industry Mixer Settler

VIEW MORENickel Cobalt Industry Mixer Settler VIEW MORESalt Lake Brine Industry Mixer Settler

VIEW MORESalt Lake Brine Industry Mixer Settler VIEW MOREBiological Wastewater Industry Mixer Settler

VIEW MOREBiological Wastewater Industry Mixer Settler VIEW MOREBattery Mixer Settler

VIEW MOREBattery Mixer Settler