Box Type Mixer Settler

Configuration:desktop base edition, mobile standard edition, environmentally friendly high edition

Mixing volumn: 200ml, 300ml, 500ml, 1L, 2L, 3L or customized

Plate thickness:5mm,6mm,8mm,10mm

Material: PP,PPH,PVC,transparent PVC,PMMA,PTFE,PEEK,SUS,Ti

Production process: welding,bonding,bending,injection molding,integral forming

Optional function: temperature control device, pH adjustment device, water-bath jacket device, anti-overflow tank device,watch window device

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable mixer-settler stage amount, adjustable agitator speed, and adjustable phase interface height;Highly customizable

Application:rare earth extraction;nickel cobalt extraction;rubidium cesium extraction;salt lake brine extraction;nuclear extraction;isotope extraction;lithium battery recycling;vanadium battery recycling;copper electroplate recycling;biological wastewater recycling

- Product Description

Shaanxi Cuiyan: Your Trusted Box Type Mixer Settler Manufacturer & Supplier

As a leading box type mixer settler manufacturer since 2012, Shaanxi Cuiyan Technology Co., Ltd. combines cutting-edge engineering with 12+ years of industry expertise. Our modular, corrosion-resistant equipment serves 300+ global clients across metallurgy, lithium recycling, and chemical sectors, offering unmatched customization (PP to titanium materials), automation integration, and energy-saving designs.

Box Type Mixer Settler Description

The box type mixer settler is a compact, modular unit for liquid-liquid extraction, ideal for lab-to-industrial applications. Designed for rare earth separation, battery metal recovery, and nuclear processing, it ensures precise phase mixing, rapid settling, and leak-free operation.

Specifications

| Parameter | Options |

|---|---|

| Configuration | Desktop Base Edition, Mobile Standard Edition, Eco-Friendly High Edition |

| Mixing Volume | 200ml–3L (Standard) / Customized up to 500L |

| Plate Thickness | 5mm, 6mm, 8mm, 10mm |

| Material | PP, PPH, PVC, Transparent PVC, PMMA, PTFE, SUS, Ti |

| Production Process | Welding, Bonding, Injection Molding, Integral Forming |

| Optional Functions | Temperature Control, pH Adjustment, Anti-Overflow Tank, Watch Window |

Why Choose Our Box Type Mixer Settler?

- High Extraction Efficiency – Achieve >95% metal recovery with optimized agitation and settling zones.

- Zero Leakage Guarantee – Robust seals and welded joints ensure safe handling of corrosive fluids.

- Smart Customization – Add sensors (pH, temperature), adjust stage counts, or integrate with PLC systems.

- Energy-Saving Design – Low power consumption and modular scalability reduce operational costs.

Material & Processing

- Corrosion Resistance: SUS316L and PTFE options for acidic/alkaline environments (e.g., nickel-cobalt extraction).

- Transparency: PMMA or PVC watch windows for real-time process monitoring.

- Precision Fabrication: Laser-cut plates and CNC-machined components ensure <0.5mm assembly tolerance.

How It Works

- Mixing Stage: Agitators blend two immiscible phases (organic/aqueous) to transfer target ions.

- Settling Zone: Laminar flow design accelerates phase separation, minimizing carryover.

- Adjustable Controls: Modify mixer speed, phase interface height, and flow rates via touchscreen.

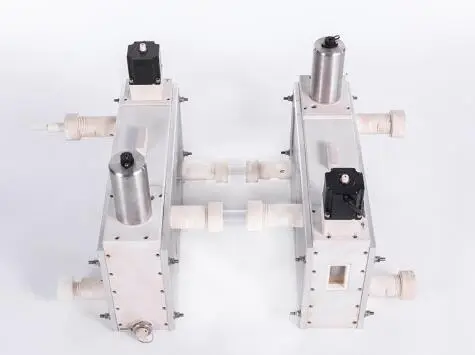

Physical Display

These box type mixer settler displays show the actual items. High-quality images offer a clear visual reference. Our team is here to provide full details and answer all your questions.

User Guide

- Installation: Bolt modules onto frames (1–2 hours for 10-stage systems).

- Operation: Set parameters via HMI panel; monitor via integrated sensors.

- Maintenance: Replace agitator seals annually; clean with non-abrasive solvents.

Applications

- Rare Earth & Battery Metals: Lithium, cobalt, rubidium recovery from ores or e - waste

In the pursuit of lithium, cobalt, and rubidium, we tap into multiple sources. From ores, we employ a combination of crushing, grinding, and chemical leaching. For lithium - bearing ores, acid leaching helps dissolve the metal, followed by precipitation techniques. Cobalt recovery from sulfide ores involves roasting and subsequent hydrometallurgical processes. When it comes to e - waste, dismantling and shredding are initial steps. Then, through chemical treatment, we can extract these valuable metals, reducing reliance on virgin mining and promoting a circular economy. - Nuclear & Isotopes: Uranium/plutonium separation with radiation - resistant materials

Separation of uranium and plutonium in the nuclear field demands utmost precision and safety. We utilize radiation - resistant materials like specialized alloys and polymers in the equipment. The process starts with the dissolution of nuclear materials. Solvent extraction methods, using ligands that selectively bind to uranium or plutonium, are then applied. These radiation - resistant materials ensure the integrity of the separation process, protecting against the harsh radioactive environment and enabling the production of high - purity nuclear materials for power generation and research. - Chemical & Pharma: Solvent extraction for APIs or high - purity compounds

In chemical and pharmaceutical industries, solvent extraction is a cornerstone for obtaining Active Pharmaceutical Ingredients (APIs) and high - purity compounds. The process begins with dissolving the raw material mixture in a suitable solvent. Different solvents are then used to selectively extract the desired compound based on solubility differences. For APIs, this multi - step extraction, followed by purification techniques like crystallization, ensures that the final product meets strict purity standards, guaranteeing the safety and efficacy of medications.

Packaging & Transportation

Crates with shock-absorbent foam protect equipment during global shipping.

After-Sales Service

24/7 remote troubleshooting, on-site training, and 2-year warranty.

Certifications

ISO 9001, CE, and RoHS-compliant manufacturing.

FAQ

Q1: Can you customize mixer-settlers for radioactive environments?

Yes! We offer lead-shielded SUS316L units with remote monitoring.

Q2: Which material suits sulfuric acid leaching?

PPH or PTFE-lined tanks resist 98% H₂SO₄ at 80°C.

Q3: Lead time for a 10-stage system?

20–30 days (standard) or 45 days (customized).

Q4: Do you provide ISO certificates?

Yes, available upon request.

Q5: Can this handle lithium brine with high Mg/Li ratios?

Absolutely – our stacked designs improve Li selectivity by 40%.

Contact Us

Ready to upgrade your extraction process? Email wangzhijun@cuiyan-tec.com for a free consultation of box type mixer settler.

VIEW MORELiquid Liquid Extraction Equipment

VIEW MORELiquid Liquid Extraction Equipment VIEW MORELiquid Liquid Extraction Equipment

VIEW MORELiquid Liquid Extraction Equipment VIEW MORELab Mixer Settler

VIEW MORELab Mixer Settler VIEW MORERare Earth Industry Mixer Settler

VIEW MORERare Earth Industry Mixer Settler VIEW MOREPilot Solvent Extractor

VIEW MOREPilot Solvent Extractor VIEW MOREPilot Liquid Liquid Extractor

VIEW MOREPilot Liquid Liquid Extractor VIEW MOREMicro Extraction Equipment

VIEW MOREMicro Extraction Equipment VIEW MOREEquipment For Liquid Liquid Extraction

VIEW MOREEquipment For Liquid Liquid Extraction