Pilot Extraction Equipment

Configuration:mobile platform edition, skid mounted edition

Mixing volumn: 8L,10L,20L,40L,60L,80L or customized

Plate thickness:8mm,10mm,12mm,15mm

Material: PP,PPH,PVC,transparent PVC,PMMA

Production process: welding,bonding

Optional function: temperature control device, pH adjustment device, anti-overflow tank device,watch window device

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable mixer-settler stage amount, adjustable agitator speed, and adjustable phase interface height;Highly customizable

Application:rare earth extraction;nickel cobalt extraction;rubidium cesium extraction;salt lake brine extraction;nuclear extraction;vanadium battery recycling;copper electroplate recycling;biological wastewater recycling

- Product Description

Shaanxi Cuiyan: Your Trusted Pilot Extraction Equipment Manufacturer & Supplier

Shaanxi Cuiyan Technology Co., Ltd, established in 2012, specializes in designing and manufacturing high-performance pilot extraction equipment for industries like rare metals, chemicals, and environmental protection. With 37+ experts, 9,000+ stages sold, and 300+ global clients, our equipment combines automation, modularity, and energy efficiency to deliver precise, scalable solutions.

Pilot Extraction Equipment Specifications

| Specification | Details |

|---|---|

| Configuration | Mobile Platform Edition, Skid-Mounted Edition |

| Mixing Volume | 8L, 10L, 20L, 40L, 60L, 80L (Customizable) |

| Material | PP, PPH, PVC, Transparent PVC, PMMA |

| Plate Thickness | 8mm, 10mm, 12mm, 15mm |

| Production Process | Welding, Bonding |

| Optional Functions | Temperature Control, pH Adjustment, Anti-Overflow Tank, Observation Window |

Why Choose Our product?

- Proven Expertise: Backed by 12+ years of R&D and national patents.

- Customization: Sensors (pH, temperature, liquid level), modular stages, and industry-specific designs.

- Efficiency: High extraction rates, zero leakage, and adjustable mixer speeds.

- Certifications: Compliant with ISO, CE, and REACH standards.

- Scalability: Seamlessly upgrade from pilot to industrial-scale systems.

Durable Materials & Advanced Processing

We use corrosion-resistant polymers (PP, PPH) and transparent materials (PMMA) for visibility and longevity. Components are welded or bonded to ensure leak-proof performance, even under aggressive chemical conditions.

Key Functions

- Precision Control: Automate phase separation and adjust interface height.

- Anti-Bubbling Design: Minimize cross-contamination.

- Energy-Saving Operation: Reduce power consumption by 20% vs. conventional systems.

How It Works

Our pilot extraction equipment uses a mixer-settler mechanism:

- Mixing: Agitation creates surface area for efficient mass transfer.

- Settling: Phases separate naturally in clarification tanks.

- Automation: Sensors monitor parameters for consistent output.

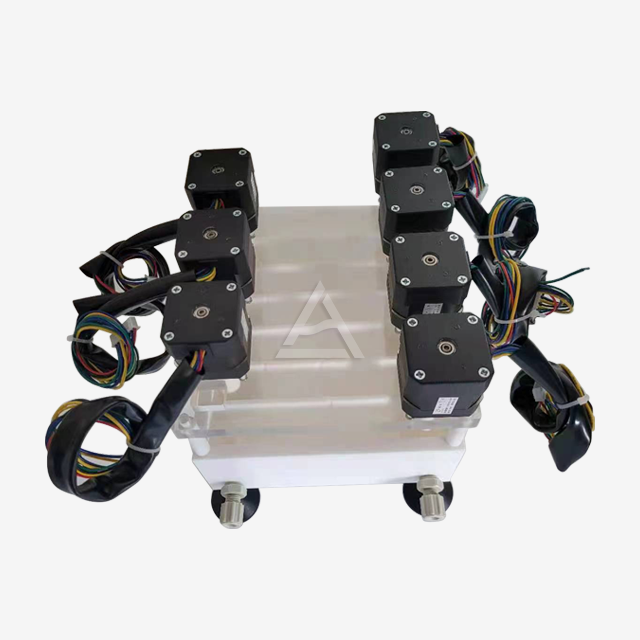

Physical Display

These pictures show the real appearance of our machines. They are designed to help you visually evaluate product details. Get in touch for more technical support.

User Guide

- Setup

During setup, the first crucial step is to select a stable platform for mounting the equipment. A sturdy surface, free from vibrations and unevenness, is essential to ensure the smooth operation of the unit. Once the platform is chosen, carefully mount the equipment using appropriate fasteners. After mounting, connect the power lines, making sure to follow electrical safety guidelines. Then, attach the feed lines, ensuring a secure fit to prevent leaks. Double - check all connections before powering on to avoid any operational issues. - Calibration

Calibration is key to optimizing the performance of the equipment. Using the control panel, which is designed to be user - friendly, set the mixer speed. The speed can be adjusted according to the viscosity of the substances being processed. For example, a lower speed might be suitable for delicate mixing, while a higher speed is required for more viscous materials. Additionally, set the phase height, which is crucial for processes involving the separation of immiscible phases. Precise calibration ensures efficient operation and high - quality results. - Operation

During operation, closely monitor the real - time data provided by the built - in sensors. These sensors can track variables such as temperature, pressure, and flow rate. By observing this data, you can detect any anomalies or deviations from the desired parameters. If necessary, make adjustments to parameters like mixer speed or feed rates. For instance, if the temperature is rising too quickly, you might reduce the mixer speed. Constant monitoring and adjustment ensure the equipment runs smoothly and the process yields the expected outcomes.

Applications of Our product

- Metals: Rare earth, nickel-cobalt, rubidium-cesium extraction.

- Energy: Vanadium battery recycling, salt lake brine processing.

- Environment: Biological wastewater treatment, copper electroplating recovery.

- Pharma: Active ingredient isolation, solvent purification.

Packaging & Transportation

Equipment is crated in shock-proof, moisture-resistant packaging for global shipping.

After-Sales Service

24/7 technical support, on-site training, and a 2-year warranty.

Certifications

ISO 9001, CE, and REACH-compliant.

FAQ

Q: Can I customize the mixing volume?

A: Yes! We offer volumes from 8L to 80L, with fully bespoke designs.

Q: Are your materials FDA-approved?

A: Select materials meet FDA standards for pharmaceutical use.

Q: What's the delivery time?

A: 4–6 weeks for standard units; 8–10 weeks for customized orders.

Q: Do you provide installation support?

A: Yes – our engineers can assist with setup and calibration.

Q: Can this scale to industrial production?

A: Absolutely! Our modular design ensures seamless scalability.

Contact Us

Ready to optimize your extraction process? Email wangzhijun@cuiyan-tec.com for a quote or consultation of pilot extraction equipment.