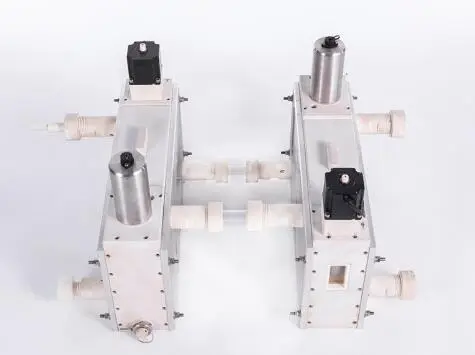

Mixer Settler Equipment

Configuration:desktop base edition, mobile standard edition, environmentally friendly high edition

Mixing volumn: 200ml, 300ml, 500ml, 1L, 2L, 3L or customized

Plate thickness:5mm,6mm,8mm,10mm

Material: PP,PPH,PVC,transparent PVC,PMMA,PTFE,PEEK,SUS,Ti

Production process: welding,bonding,bending,injection molding,integral forming

Optional function: temperature control device, pH adjustment device, water-bath jacket device, anti-overflow tank device,watch window device

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable mixer-settler stage amount, adjustable agitator speed, and adjustable phase interface height;Highly customizable

Application:rare earth extraction;nickel cobalt extraction;rubidium cesium extraction;salt lake brine extraction;nuclear extraction;isotope extraction;lithium battery recycling;vanadium battery recycling;copper electroplate recycling;biological wastewater recycling

- Product Description

Shaanxi Cuiyan: Your Trusted Mixer Settler Equipment Manufacturer & Supplier

Shaanxi Cuiyan Technology Co., Ltd, established in 2012, is a leading mixer settler equipment manufacturer specializing in lab, pilot, and industrial-scale extraction systems. With 37+ technical experts and 9 patented innovations, we've delivered 10,000+ stages of extraction equipment to 300+ global clients. Our lab-scale models combine automation, modularity, and corrosion-resistant materials to meet demanding applications like rare earth separation and lithium battery recycling.

Mixer Settler Equipment Description

Our lab-scale mixer settler equipment is engineered for precise solvent extraction in research and small-scale production. Designed with flexibility in mind, it supports customization across materials, volumes, and functions to match your unique process requirements.

Key Features

- High extraction efficiency (≥95%) and phase separation accuracy.

- Leak-proof design with reinforced seals.

- Adjustable agitator speed (0–500 RPM) and phase interface control.

- Optional sensors (pH, temperature, liquid level) for real-time monitoring.

Specifications

| Parameter | Options |

|---|---|

| Configuration | Desktop Base, Mobile Standard, Eco-Friendly High Edition |

| Mixing Volume | 200mL – 3L (Customizable up to 5L) |

| Material | PP, PPH, PVC, PMMA, PTFE, SUS 316/304, Titanium |

| Plate Thickness | 5mm – 10mm |

| Production Process | Welding, Bonding, Injection Molding, Integral Forming |

| Optional Functions | Temperature Control, pH Adjustment, Anti-Overflow Tank, Water-Jacket Cooling |

Why Choose Our Mixer Settler Equipment?

- Automation Ready: Integrate with PLC/DCS systems for hands-free operation (IEC 61131-3 compliant).

- Anti-Bubbling Tech: Patented tank design prevents emulsification, ensuring clean phase separation.

- Modular & Scalable: Add or remove stages in hours, ideal for multi-process R&D.

- Industry-Specific Customization: Tailored solutions for nuclear fuel reprocessing, battery recycling, and more.

Material & Processing

- PP/PTFE: Ideal for acidic/alkaline environments (pH 1–14).

- SUS 316/Titanium: Perfect for high-temperature, high-corrosion nuclear/chemical applications.

- PMMA/Transparent PVC: Clear visibility for process observation.

- Precision Welding: Laser-calibrated joints ensure zero leakage.

How It Works

- Mixing Stage: The impeller creates intense turbulence, enabling rapid mass transfer between phases.

- Settling Stage: Lamella plates accelerate phase separation, achieving clarity in ≤5 minutes.

- Interface Control: Adjustable weirs maintain optimal organic/aqueous phase ratios.

Applications

- Rare Earths: La, Ce, Nd separation

In the domain of rare earths, separating lanthanum (La), cerium (Ce), and neodymium (Nd) is a complex yet crucial process. Initially, the rare earth ore is subjected to crushing and grinding to liberate the valuable elements. Chemical leaching follows, using acids to dissolve the metals. Solvent extraction techniques are then employed, where specific organic solvents are used to selectively extract each element based on their chemical properties. Multiple extraction and stripping cycles are carried out to achieve high - purity separation. The separated La, Ce, and Nd are essential for applications in electronics, magnets, and clean energy technologies. - Battery Recycling: Li, Co, Ni recovery from spent lithium - ion batteries

With the exponential growth of electric vehicles, recycling spent lithium - ion batteries has become imperative. The process starts with mechanical dismantling of the batteries to separate the casing and other non - metallic components. The remaining battery materials are then treated with acids in a chemical leaching step to dissolve lithium (Li), cobalt (Co), and nickel (Ni). Subsequent precipitation and purification methods, such as ion - exchange and solvent extraction, are used to isolate and recover these metals. The recovered Li, Co, and Ni can be reused in new battery manufacturing, reducing both environmental waste and the reliance on virgin mining resources. - Nuclear: Uranium/plutonium purification

Purifying uranium and plutonium in the nuclear field is a highly specialized and tightly regulated process. Uranium ore is first processed to obtain uranium concentrate. This concentrate undergoes further purification using solvent extraction and ion - exchange methods to remove impurities. Plutonium, which is produced in nuclear reactors, requires even more intricate purification due to its high radioactivity. Advanced chemical separation techniques, such as pyrochemical processes and liquid - liquid extraction with specific reagents, are used. High - purity uranium and plutonium are essential for nuclear power generation, nuclear fuel reprocessing, and maintaining nuclear non - proliferation standards. - Wastewater: Heavy metal removal (Pb, Hg, Cd)

Removing heavy metals like lead (Pb), mercury (Hg), and cadmium (Cd) from wastewater is crucial for environmental protection. The process typically begins with chemical precipitation, where chemicals such as lime or sodium sulfide are added to the wastewater. These react with the heavy metals to form insoluble compounds that can be separated by sedimentation or filtration. Ion - exchange resins are also used to capture any remaining traces of heavy metal ions. Additionally, advanced treatment methods like membrane filtration can be employed for highly contaminated wastewater. By reducing the heavy metal content, we protect water bodies, prevent soil contamination, and safeguard human health.

FAQ

Q: Can you customize mixer settler stages for high-viscosity fluids?

A: Yes! We offer oversized agitators and tapered settling zones for viscous media.

Q: What's the lead time for a 2L customized unit?

A: Standard lead time is 4–6 weeks, expedited to 3 weeks for urgent needs.

Q: Do your systems comply with ATEX directives?

A: We provide explosion-proof versions (ATEX Zone 1/21) for solvent-rich environments.

Q: How often is maintenance required?

A: Annual seal inspections suffice under normal conditions.

Q: Can I upgrade my existing unit with automation?

A: Absolutely – our retrofit kits enable smart control within 48 hours.

Contact Us

For more information about our mixer settler equipment, including pricing, customization options, and bulk orders, please feel free to reach out to us:📧 Email: wangzhijun@cuiyan-tec.com.