Mixer Settler Systems

Configuration:desktop base edition, mobile standard edition, environmentally friendly high edition

Mixing volumn: 200ml, 300ml, 500ml, 1L, 2L, 3L or customized

Plate thickness:5mm,6mm,8mm,10mm

Material: PP,PPH,PVC,transparent PVC,PMMA,PTFE,PEEK,SUS,Ti

Production process: welding,bonding,bending,injection molding,integral forming

Optional function: temperature control device, pH adjustment device, water-bath jacket device, anti-overflow tank device,watch window device

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable mixer-settler stage amount, adjustable agitator speed, and adjustable phase interface height;Highly customizable

Application:rare earth extraction;nickel cobalt extraction;rubidium cesium extraction;salt lake brine extraction;nuclear extraction;isotope extraction;lithium battery recycling;vanadium battery recycling;copper electroplate recycling;biological wastewater recycling

- Product Description

Shaanxi Cuiyan: Your Trusted Mixer Settler Systems Manufacturer & Supplier

Shaanxi Cuiyan Technology Co., Ltd, established in 2012, is a leading mixer settler systems manufacturer specializing in lab, pilot, and industrial-scale extraction solutions. With a team of 37 experts and over 10,000 stages sold globally, our systems integrate automation, modular design, and patented innovations to deliver unmatched efficiency and reliability.

Mixer Settler Systems Specifications

| Specifications | Details |

|---|---|

| Configuration | Desktop Base Edition, Mobile Standard Edition, Environmentally Friendly High Edition |

| Mixing Volume | 200ml, 300ml, 500ml, 1L, 2L, 3L (Customizable) |

| Plate Thickness | 5mm, 6mm, 8mm, 10mm |

| Material Options | PP, PPH, PVC, Transparent PVC, PMMA, PTFE, PEEK, SUS, Ti |

| Production Process | Welding, Bonding, Bending, Injection Molding, Integral Forming |

| Optional Functions | Temperature Control, pH Adjustment, Water-Bath Jacket, Anti-Overflow Tank, Observation Window |

Why Choose Our product?

- Technical Expertise: Patented designs with anti-bubbling and one-step filling/emptying functions.

- Customization: Integrate sensors (temperature, pH, liquid level) and tailor mixing stages to your workflow.

- Efficiency: High extraction rates, adjustable agitator speeds, and energy-saving modular structures.

- Durability: Corrosion-resistant materials (e.g., PTFE for harsh chemicals, SUS 316L for high-purity applications).

Material & Processing Methods

- PP/PPH: Ideal for acidic/alkaline environments.

- Transparent PVC/PMMA: Visual monitoring of phase separation.

- PTFE/PEEK: Withstand extreme temperatures and aggressive solvents.

- Precision Fabrication: Injection molding ensures leak-proof joints; integral forming enhances structural integrity.

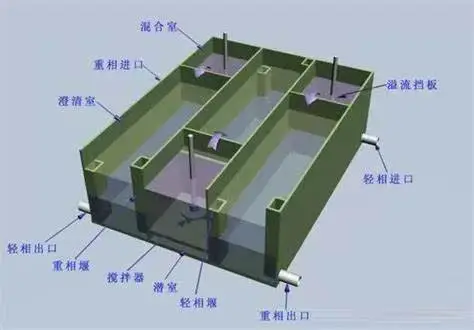

How It Works

- Mixing Phase: Agitators blend two immiscible liquids, transferring target compounds.

- Settling Phase: Liquids separate into distinct layers based on density, ensuring pure extraction.

- Automation: Optional PLC systems control interface height and flow rates for consistent results.

Applications

- Mining & Recycling: Extract rare earths, lithium, cobalt, or recover metals from batteries

In the mining aspect, extracting rare earths like neodymium and dysprosium involves complex processes starting from ore mining, followed by crushing, grinding, and chemical leaching. Lithium extraction often comes from salt lakes or hard rock ores, using techniques such as evaporation and solvent extraction. Cobalt mining, crucial for batteries, is similarly intricate. Recycling efforts focus on retrieving metals from spent batteries. Dismantling batteries, leaching the components, and then separating and purifying lithium, cobalt, and other metals is key to reducing reliance on virgin mining and minimizing environmental impact. - Pharmaceuticals: Purify APIs or isolate bioactive compounds

For purifying Active Pharmaceutical Ingredients (APIs), the pharmaceutical industry employs advanced chromatography techniques. High - performance liquid chromatography (HPLC) separates the API from impurities based on their different affinities for the stationary and mobile phases. Multiple purification steps may be required to achieve the high - purity levels demanded by regulatory bodies. Isolating bioactive compounds, on the other hand, often begins with extraction from natural sources like plants or microorganisms. This is followed by a series of separation and purification methods to obtain the desired compound in its pure form for drug development. - Nuclear & Environmental: Process radioactive isotopes or treat industrial wastewater

In the nuclear field, processing radioactive isotopes involves handling highly radioactive materials with extreme care. Techniques such as isotope separation for medical or research - grade isotopes are carried out in specialized facilities. This may include methods like electromagnetic separation. In environmental applications, treating industrial wastewater is essential. Processes like chemical precipitation, filtration, and biological treatment are used to remove heavy metals, organic pollutants, and other contaminants from industrial effluents. This ensures that the wastewater meets environmental standards before being discharged, protecting water bodies and ecosystems.

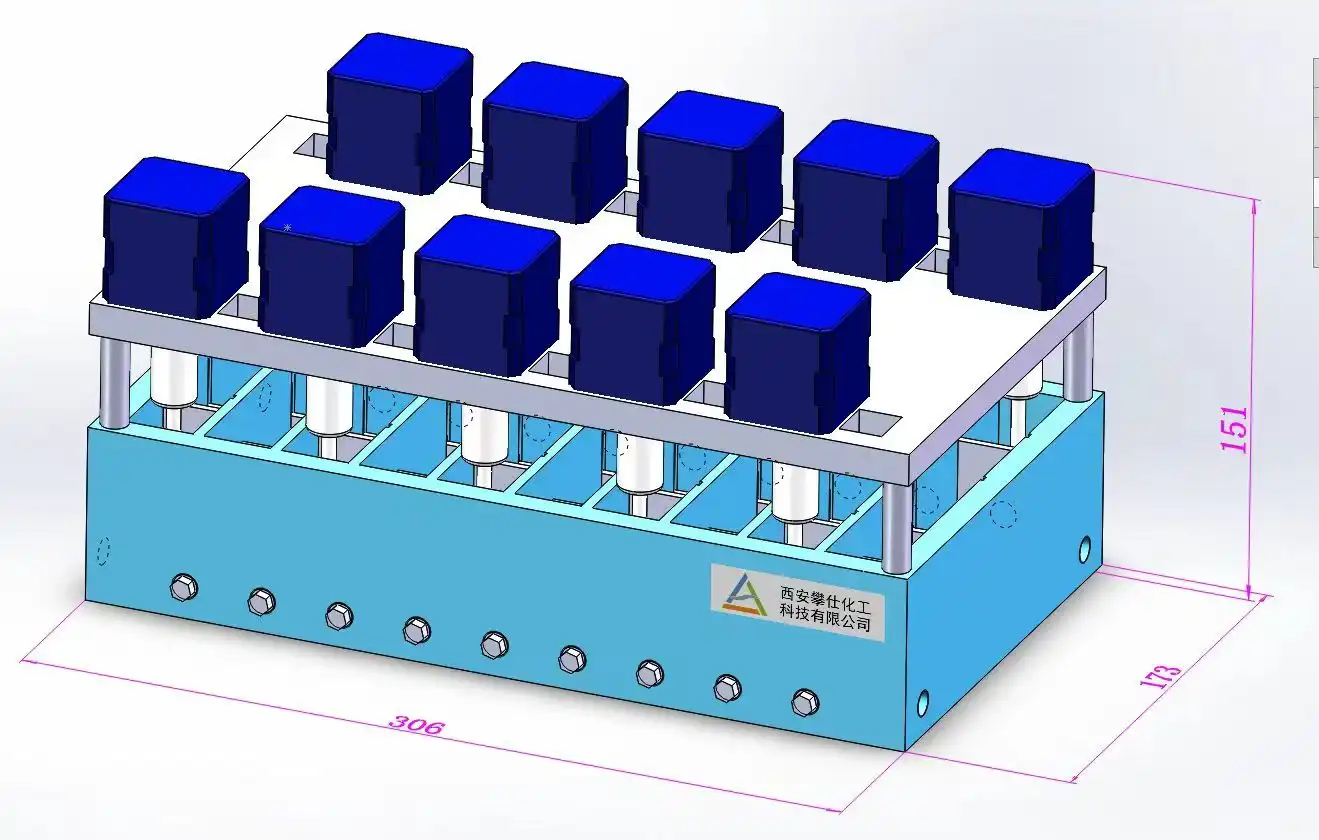

Physical Display

Here we provide a real mixer settler systems demonstration. The pictures clearly show the appearance of the product. You can contact us at any time and we will provide you with more information.

Packaging

Shock-resistant crates with moisture control for safe global shipping.

After-Sales

12-month warranty + lifetime technical support.

Certifications

ISO 9001, CE, and REACH compliance.

FAQ

Q: Can I customize the number of stages?

A: Yes! Adjust stages from 1 to 20+ to match your process scalability.

Q: Which material suits high-temperature extraction?

A: PTFE or PEEK materials excel in environments up to 200°C.

Q: What's the lead time for a custom order?

A: Typically 4–6 weeks, depending on design complexity.

Q: Are your systems compliant with GMP standards?

A: We offer SUS 316L and polished surfaces for pharmaceutical-grade compliance.

Q: Do you provide process optimization support?

A: Our engineers offer free consultation to maximize extraction efficiency.

Contact Us

Xi'an Plansee's mixer settler systems combine innovation with practicality. Contact us at wangzhijun@cuiyan-tec.com to discuss your project – let's optimize your extraction process today!

VIEW MOREMultistage Liquid Liquid Extraction

VIEW MOREMultistage Liquid Liquid Extraction VIEW MORELiquid Liquid Extraction Of Rubidium Cesium

VIEW MORELiquid Liquid Extraction Of Rubidium Cesium VIEW MORELaboratory Mixer Settlers

VIEW MORELaboratory Mixer Settlers VIEW MOREPilot Liquid Liquid Extraction

VIEW MOREPilot Liquid Liquid Extraction VIEW MOREMicro Mixer Settler

VIEW MOREMicro Mixer Settler VIEW MOREMicro Liquid Liquid Extraction

VIEW MOREMicro Liquid Liquid Extraction VIEW MORELiquid Liquid Extraction Equipment Laboratory

VIEW MORELiquid Liquid Extraction Equipment Laboratory VIEW MORENuclear Industry Mixer Settler

VIEW MORENuclear Industry Mixer Settler