Mixer Settler For Liquid Liquid Extraction

Configuration:desktop base edition, mobile standard edition, environmentally friendly high edition

Mixing volumn: 200ml, 300ml, 500ml, 1L, 2L, 3L or customized

Plate thickness:5mm,6mm,8mm,10mm

Material: PP,PPH,PVC,transparent PVC,PMMA,PTFE,PEEK,SUS,Ti

Production process: welding,bonding,bending,injection molding,integral forming

Optional function: temperature control device, pH adjustment device, water-bath jacket device, anti-overflow tank device,watch window device

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable mixer-settler stage amount, adjustable agitator speed, and adjustable phase interface height;Highly customizable

Application:rare earth extraction;nickel cobalt extraction;rubidium cesium extraction;salt lake brine extraction;nuclear extraction;isotope extraction;lithium battery recycling;vanadium battery recycling;copper electroplate recycling;biological wastewater recycling

- Product Description

Shaanxi Cuiyan: Your Trusted Mixer Settler For Liquid Liquid Extraction Manufacturer & Supplier

Shaanxi Cuiyan Technology Co., Ltd – Your trusted Mixer Settler For Liquid Liquid Extraction manufacturer since 2012. With 37+ experts, 9 patented technologies, and 10,000+ stages sold globally, we deliver corrosion-resistant, modular, and fully customizable equipment tailored for industries like rare earth extraction, pharmaceuticals, and wastewater recycling.

Mixer Settler For Liquid Liquid Extraction Description

Optimize your lab-scale liquid-liquid extraction processes with our versatile mixer settlers. Designed for precision, our Mixer Settler For Liquid Liquid Extraction ensures high extraction rates, leak-free operation, and seamless integration with automation systems.

Specifications

| Parameter | Options |

|---|---|

| Configuration | Desktop Base Edition, Mobile Standard Edition, Eco-Friendly High Edition |

| Mixing Volume | 200mL, 300mL, 500mL, 1L, 2L, 3L (Customizable) |

| Material | PP, PPH, PVC, Transparent PVC, PMMA, PTFE, PEEK, SUS, Ti |

| Plate Thickness | 5mm, 6mm, 8mm, 10mm |

| Production Process | Welding, Bonding, Bending, Injection Molding, Integral Forming |

| Optional Functions | Temperature Control, pH Adjustment, Anti-Overflow Tank, Water-Bath Jacket |

Why Choose Our product?

- Modular & Scalable: Rapid installation and expansion for multi-stage extraction.

- Energy-Saving Design: Reduce operational costs with optimized agitation and phase separation.

- Anti-Bubbling Tech: Ensure stable separation with our patented tank-filling system.

- Sensor Integration: Monitor pH, temperature, and liquid levels in real time.

- 10+ Material Choices: Match equipment to corrosive or high-purity media.

Materials & Processing Methods

- Corrosion Resistance: SUS316L, PTFE, and titanium options for acidic/alkaline environments.

- Transparency: PMMA or PVC viewing windows for process monitoring.

- Precision Fabrication: CNC-machined parts with ISO 9001-certified welding.

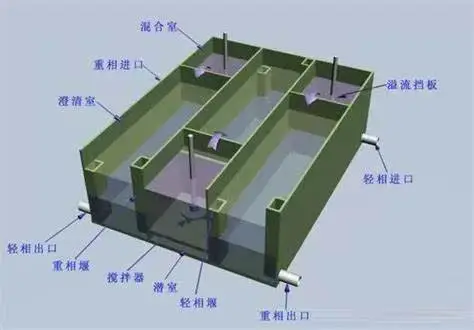

How It Works

- Mixing Stage: Adjustable agitators create intense contact between immiscible phases.

- Settling Zone: Laminar flow design ensures rapid phase separation.

- Custom Controls: Automate flow rates, interface levels, and agitation speed via PLC.

Applications

- Metals: Rare earth, nickel, cobalt, lithium recovery.

- Pharma: API purification, solvent extraction.

- Environmental: Heavy metal removal, battery recycling.

- Nuclear: Isotope separation, radioactive waste treatment.

Physical Display

These are real displays of our Mixer Settler For Liquid Liquid Extraction. You can get a clear visual impression through the pictures provided. We're also here to offer detailed information and answer your questions.

User Guide

- Step 1: Select mixing volume and material based on chemical compatibility

In the initial step, a careful assessment of the mixing requirements is essential. Consider the scale of the operation to determine the appropriate mixing volume. Small - scale laboratory experiments may require a few milliliters, while industrial applications could demand several thousand liters. Equally crucial is choosing a mixing material, such as stainless steel, glass - lined reactors, or specialized polymers. This selection is based on the chemical nature of the substances being mixed. For highly corrosive chemicals, materials like Hastelloy or Teflon - coated vessels are ideal, ensuring no chemical reactions between the container and the reactants, thus maintaining the integrity of the process. - Step 2: Integrate sensors (pH/temperature) for automated feedback

Integrating pH and temperature sensors into the mixing system is a key advancement. The pH sensor continuously monitors the acidity or alkalinity of the mixture. This is vital as many chemical reactions are highly pH - dependent; a slight deviation can alter reaction rates or even lead to unwanted by - products. The temperature sensor, on the other hand, tracks the heat generated or absorbed during the mixing process. Both sensors are connected to a control unit that provides automated feedback. If the pH or temperature goes out of the pre - set range, the system can adjust parameters like the addition of pH - adjusting chemicals or the cooling/heating rate to maintain optimal conditions. - Step 3: Optimize agitation speed (50–500 RPM) via digital interface

The agitation speed significantly impacts the mixing efficiency. Using the digital interface, operators can precisely set the speed within the 50 - 500 RPM range. For less viscous liquids, a lower speed around 50 - 100 RPM may be sufficient for gentle blending, ensuring that delicate components are not damaged. In contrast, more viscous substances or when rapid mass transfer is required, such as in chemical reactions where reactants need to mix quickly, a higher speed, perhaps 300 - 500 RPM, is more appropriate. Regularly adjusting the speed based on real - time observations of the mixing process, like the uniformity of color or the disappearance of reactant gradients, helps in achieving the best possible mixing results.

Packaging & Transportation

Crush-proof foam and waterproof packaging ensure safe global delivery.

After-Sales Service

24/7 technical support, 2-year warranty, and spare parts supply.

Qualification Certification

ISO 9001, CE, and REACH-compliant.

FAQs

Q: Can you customize mixer settlers for high-viscosity fluids?

A: Yes! We design agitators and baffles for viscosities up to 10,000 cP.

Q: What's the lead time for a 3L customized unit?

A: 4–6 weeks, including testing and documentation.

Q: Do you support ATEX-certified explosion-proof systems?

A: Absolutely. We provide ATEX-compliant motors and control panels.

Q: Can I upgrade my desktop unit to mobile later?

A: Yes! Our modular design allows easy reconfiguration.

Q: How do I clean PTFE tanks after organic extraction?

A: Use our CIP (Clean-in-Place) kit with solvent-resistant spray nozzles.

Contact Us

Elevate your Mixer Settler For Liquid Liquid Extraction efficiency today! Email wangzhijun@cuiyan-tec.com for a free consultation or request a lab demo.