Micro Mixer Settler Tank

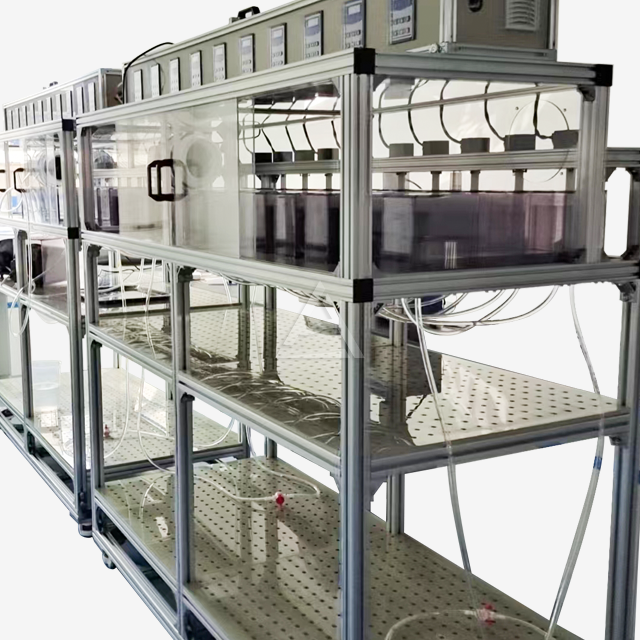

Configuration:simple desktop platform edition

Mixing volumn: 20ml, 25ml, 50ml, 80ml, 100ml, 125ml or customized

Wall thickness:8mm,10mm,12mm

Material: PMMA,PTFE,PEEK,Ti

Production process: CNC integral forming

Matching equipment: Optional micro injection pump

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable mixer-settler stage amount, adjustable agitator speed;Highly customizable

Application:nuclear extraction industry;isotope extraction industry;solvent extraction agent industry

- Product Description

Shaanxi Cuiyan: Your Trusted Micro Mixer Settler Tank Manufacturer & Supplier

Shaanxi Cuiyan Technology Co., Ltd, established in 2012, is a leading micro mixer settler tank manufacturer and supplier specializing in lab-to-industrial-scale extraction equipment. With 37+ experts from top Chinese universities, we deliver highly customizable, corrosion-resistant solutions that integrate automation, energy-saving designs, and modular scalability—trusted by 300+ global clients.

Micro Mixer Settler Tank Description

Our micro mixer settler tank is engineered for precision solvent extraction in nuclear, isotope, and chemical research. Designed as a compact desktop platform, it ensures zero leakage, adjustable agitation speed, and seamless integration with micro-injection pumps.

Specifications

| Specifications | Details |

|---|---|

| Mixing Volume Options | 20ml, 25ml, 50ml, 80ml, 100ml, 125ml, or fully customized |

| Material Choices | PMMA, PTFE, PEEK, Titanium (anti-corrosion, high-temperature resistant) |

| Wall Thickness | 8mm, 10mm, 12mm (sturdy, leak-proof design) |

| Production Process | CNC Integral Forming (precision engineering) |

| Matching Equipment | Optional Micro Injection Pump (enhanced flow control) |

Why Choose Our product?

- Patented Anti-Bubbling Technology: Ensures smooth phase separation.

- Modular Design: Swap stages or expand capacity in minutes.

- Energy-Efficient: Reduces power consumption by 20% vs. traditional models.

- Sensor Integration: Monitor pH, temperature, and liquid levels in real time.

- 10,000+ Stages Sold: Proven reliability across industries.

Material & Processing Excellence

Crafted from PTFE or PEEK for unmatched chemical resistance, each micro mixer settler tank undergoes CNC machining to achieve micron-level accuracy. Titanium models are ideal for radioactive or high-purity applications.

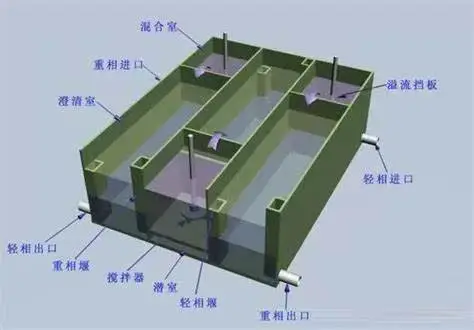

How It Works

- Mixing Phase: Adjustable agitators blend solvents at 50–500 RPM.

- Settling Phase: Gravity-driven separation with anti-turbulence baffles.

- Output: High-purity extract collected via precision valves.

User Guide

- Setup

The setup process is straightforward yet crucial for a seamless operation. First, carefully mount the tank onto your lab bench, ensuring it is placed on a flat and stable surface to prevent any accidental tipping. The tank's design allows for easy integration into your laboratory setup. If your experiment requires fluid transfer, connect the optional pumps. Make sure all connections are secure to avoid leaks. Check the tubing for any kinks or blockages before proceeding. This initial setup paves the way for accurate and efficient experimentation. - Calibration

Calibration is key to achieving precise results. Use the digital controller to set the agitation speed. The digital interface is user - friendly, allowing you to input the exact RPM (revolutions per minute) required for your specific experiment. Whether you need a slow, gentle agitation for delicate substances or a high - speed mix for more viscous solvents, the controller offers fine - tuned control. Calibrating the agitation speed according to your experiment's needs ensures that the mixing process is consistent and optimized for the best possible outcome. - Operation

Once setup and calibrated, it's time for operation. Begin by carefully loading the solvents into the tank, taking all necessary safety precautions. Then, start the cycle using the control panel. As the process commences, rely on the built - in sensors to monitor various parameters such as temperature, pressure, and concentration. These sensors provide real - time data, which you can use to make adjustments if needed. Monitoring via sensors allows you to ensure that the experiment progresses as expected and helps you achieve accurate and reliable results.

Applications

- Nuclear & Isotope Labs: Extract uranium, plutonium, or rare earth elements.

- Pharmaceuticals: Purify APIs or recover solvents.

- Environmental Testing: Remove heavy metals from wastewater.

Packaging & Transportation

Shockproof foam packaging with climate-controlled logistics.

After-Sales Service

24-month warranty + free lifetime technical support.

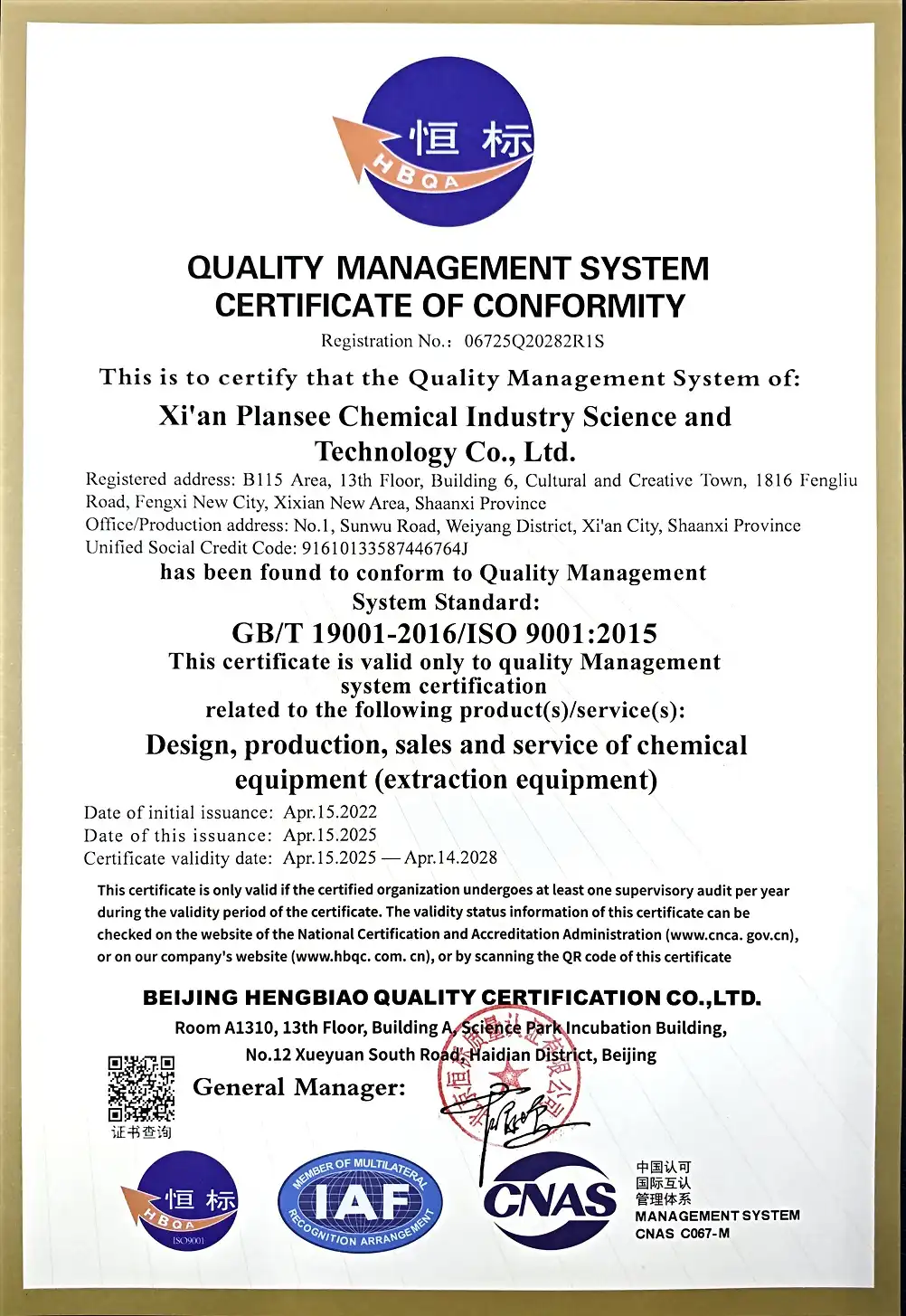

Certifications

ISO 9001, CE, and compliant with FDA/GLP standards.

FAQs

Q:Can I customize the mixing volume?

A:Yes! We tailor sizes from 20ml to 125ml+.

Q:Is the tank radiation-resistant?

A:Titanium models meet ISO 19443 for nuclear applications.

Q:What's the lead time?

A:Standard units ship in 3 weeks; custom designs take 6–8 weeks.

Q:Do you provide installation support?

A:Remote guidance via video call or on-site engineers (fee applies).

Q:How does pricing compare to competitors?

A:15–30% lower with superior durability—request a quote!

Contact Us

For more information about our micro mixer settler tank, including pricing, customization options, and bulk orders, please feel free to reach out to us:Email wangzhijun@cuiyan-tec.com.