Understanding the Basics of Extraction Equipment

Types of Extraction Equipment

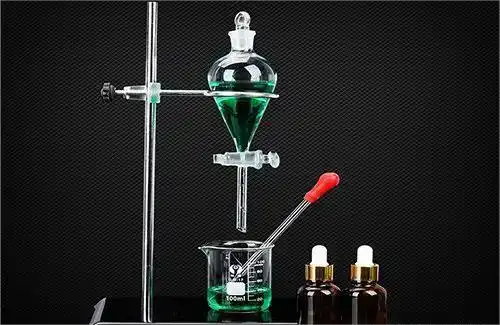

Extraction equipment comes in various forms, each designed for specific applications and materials. Common types include box-type extraction tanks, tubular extraction tanks, micro extraction tanks, centrifugal extractors, and extraction towers. These different designs cater to diverse industrial needs, from small-scale laboratory operations to large-scale manufacturing processes. For instance, box-type extraction tanks are often used for batch processing, while continuous flow systems like the product towers are suitable for high-volume production. Understanding the characteristics and capabilities of each type is crucial for selecting the most appropriate equipment for a given extraction task.

Key Components of Extraction Systems

Extraction systems typically consist of several key components that work together to facilitate the separation process. These may include feed tanks, pumps, heat exchangers, separators, and control systems. The feed tank holds the initial mixture, while pumps circulate the solvents and solutions through the system. Heat exchangers regulate temperature, which can be critical for certain extraction processes. Separators, such as decanters or centrifuges, help in isolating the desired compounds from the mixture. Advanced control systems monitor and adjust various parameters to maintain optimal extraction conditions. Familiarity with these components and their functions is essential for efficient operation and troubleshooting.

Principles of Extraction Processes

The fundamental principles underlying extraction processes involve the selective transfer of compounds from one phase to another based on their solubility differences. This can occur between liquids (liquid-liquid extraction), between a solid and a liquid (solid-liquid extraction), or even involve supercritical fluids. The efficiency of the product depends on factors such as solvent choice, temperature, pressure, and contact time between phases. Mass transfer principles, equilibrium considerations, and the properties of the materials involved all play crucial roles in the product process. A solid understanding of these principles enables operators to optimize extraction parameters and troubleshoot issues that may arise during operation.

Operational Aspects of Extraction Equipment

Setup and Preparation Procedures

Proper setup and preparation are crucial for the smooth operation of the product. This phase involves several steps, starting with equipment inspection to ensure all components are clean, properly assembled, and in good working condition. Calibration of instruments, such as flow meters and temperature sensors, is essential for accurate process control. The preparation of solvents and feed materials according to specified ratios and concentrations is another critical step. For some systems, priming of pumps and purging of lines may be necessary to eliminate air pockets and ensure consistent flow. Operators must also verify that all safety systems, including pressure relief valves and emergency shutdown mechanisms, are functional before initiating the extraction process.

Control and Monitoring Systems

Modern extraction equipment often features sophisticated control and monitoring systems that enhance ease of operation. These systems typically include user-friendly interfaces, such as touchscreen panels or computer-based control stations, allowing operators to input process parameters and monitor real-time data. Advanced systems may incorporate automated feedback loops that adjust variables like flow rates, temperatures, and pressures to maintain optimal extraction conditions. Data logging capabilities enable tracking of process performance over time, facilitating quality control and process optimization. Some equipment may also feature remote monitoring options, allowing supervisors to oversee operations from a distance and provide support when needed.

Maintenance and Cleaning Protocols

Regular maintenance and thorough cleaning are essential for ensuring the longevity and efficient operation of the product. Maintenance schedules typically include routine inspections, lubrication of moving parts, and replacement of wear items such as seals and filters. Cleaning protocols vary depending on the type of equipment and materials processed but generally involve flushing systems with appropriate solvents or cleaning solutions to remove residues and prevent cross-contamination between batches. Some equipment designs incorporate clean-in-place (CIP) systems that automate the cleaning process, reducing downtime and ensuring consistent cleanliness. Proper documentation of maintenance and cleaning activities is crucial for regulatory compliance and troubleshooting purposes.

Enhancing Operational Efficiency and Safety

Training and Skill Development for Operators

Comprehensive training programs are essential for developing skilled operators who can efficiently manage extraction equipment. These programs typically cover theoretical aspects of the product processes, equipment operation procedures, safety protocols, and troubleshooting techniques. Hands-on training sessions allow operators to gain practical experience under supervised conditions. Ongoing skill development through refresher courses and advanced training modules helps operators stay updated with new technologies and best practices. Some companies implement mentorship programs, pairing experienced operators with newcomers to facilitate knowledge transfer and skill development. Investing in operator training not only improves operational efficiency but also enhances workplace safety and product quality.

Implementing Safety Measures and Best Practices

Safety is paramount in extraction operations, given the potential hazards associated with high pressures, temperatures, and chemical exposure. Implementing robust safety measures involves several aspects, including proper personal protective equipment (PPE), emergency response procedures, and regular safety drills. Engineering controls such as ventilation systems, pressure relief valves, and interlocks play crucial roles in preventing accidents. Standard operating procedures (SOPs) should be developed and strictly followed to ensure consistent and safe operation. Regular safety audits and risk assessments help identify potential hazards and implement preventive measures. Fostering a culture of safety awareness among all staff members is essential for maintaining a safe working environment.

Optimizing Process Parameters for Efficiency

Optimizing process parameters is key to maximizing the efficiency and output quality of the product operations. This involves a systematic approach to analyzing and adjusting variables such as solvent ratios, flow rates, temperatures, and extraction times. Design of experiments (DoE) techniques can be employed to identify the most significant factors affecting extraction performance. Continuous monitoring and analysis of process data help in identifying trends and opportunities for improvement. Advanced process control strategies, such as model predictive control, can be implemented to maintain optimal conditions automatically. Regular review and updating of operating procedures based on performance data and new insights ensure that the extraction process remains efficient and competitive.

Conclusion

In conclusion, while extraction equipment is designed to be user-friendly, its ease of operation depends on various factors including proper training, understanding of the process, and adherence to best practices. Modern extraction systems offer intuitive controls and automated features that simplify many aspects of operation. However, successful management of these systems requires a solid foundation in extraction principles, safety protocols, and maintenance procedures. By investing in comprehensive training programs, implementing robust safety measures, and continuously optimizing process parameters, companies can ensure efficient and safe operation of their extraction equipment, leading to high-quality products and improved productivity.

Contact Us

Experience the efficiency and reliability of state-of-the-art extraction equipment with Cuiyan Technology. Our expertly designed systems offer ease of operation, superior performance, and optimal safety features. Take your extraction processes to the next level and boost your productivity. Contact us today at wangzhijun@cuiyan-tec.com to learn more about our innovative solutions tailored to your specific needs.