The Role of Mixer Settlers in Green Chemistry and Waste Minimization

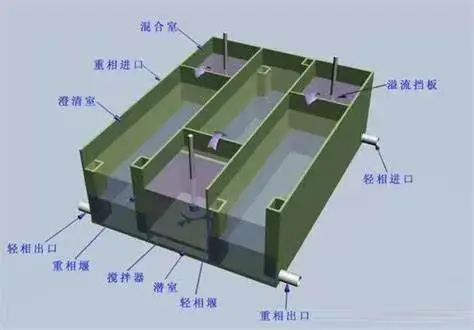

Mixer settlers play a crucial role in advancing green chemistry practices and minimizing waste in various industrial processes. These versatile devices combine mixing and settling stages to efficiently separate different phases of liquids, making them invaluable in extraction and purification processes. By optimizing the use of resources, reducing energy consumption, and maximizing product yields, mixer settlers contribute significantly to sustainable chemical production. Their ability to handle a wide range of materials, from rare earth elements to biological waste, makes them indispensable in promoting environmentally friendly practices across multiple industries.

Enhancing Extraction Efficiency and Resource Recovery

Optimizing Separation Processes

Mixer settlers are particularly effective at enhancing the precision and efficiency of separation processes, which is essential for maximizing resource recovery. Their design allows for exact control over critical parameters like mixing speed, phase contact time, and settling duration. This precision ensures high-quality phase separation, enabling industries to recover valuable components from complex mixtures. By minimizing losses and ensuring consistent performance, mixer settlers support more sustainable processing, especially in industries dealing with rare earths, pharmaceuticals, and specialty chemicals.

Reducing Solvent Usage

One of the standout benefits of using mixer settlers in sustainable chemical processes is their ability to minimize solvent consumption. Because of their high extraction efficiency, these systems achieve excellent separation with reduced solvent volume requirements. This not only lessens the environmental footprint by decreasing solvent waste and emissions but also leads to significant cost savings for manufacturers. As a result, mixer settlers align perfectly with green chemistry goals by promoting cleaner operations and reducing dependence on hazardous or expensive solvents.

Improving Material Recycling

Mixer settlers contribute significantly to advancing recycling technologies by enabling the efficient recovery of valuable resources from waste. Their effectiveness has been proven in applications like lithium-ion battery and copper electroplating recycling, where selective separation is critical. By isolating useful materials with minimal contamination, mixer settlers enhance the quality of recycled outputs and support closed-loop production cycles. This capability is vital for industries aiming to reduce raw material use, cut waste generation, and embrace circular economy principles.

Minimizing Environmental Impact in Chemical Processing

Reducing Energy Consumption

Mixer settlers offer a notable advantage in energy efficiency due to their reliance on gravity for the settling phase, which requires little to no external power input. Unlike centrifugation or distillation methods, this passive mechanism significantly reduces overall energy usage in chemical operations. As a result, industries can lower operational energy costs and meet sustainability targets more easily. This low-energy design aligns closely with green chemistry goals by promoting cleaner, more efficient processes with reduced carbon emissions.

Lowering Emissions and Waste Generation

The superior process control of mixer settlers enables cleaner operations by minimizing the generation of emissions and chemical waste. By allowing accurate control of residence time and phase contact, these systems reduce the formation of unwanted by-products. This leads to cleaner effluent streams and a lower need for post-treatment. Consequently, chemical plants can achieve better environmental compliance and reduce costs associated with waste disposal, contributing to a cleaner industrial footprint and improved public and regulatory perception.

Facilitating Closed-Loop Systems

Mixer settlers play a critical role in establishing closed-loop systems that support sustainable chemical manufacturing. Their continuous operation capability and compatibility with a broad range of chemical compositions make them ideal for reintegrating recovered materials into the production cycle. This facilitates the reuse of solvents and reagents, drastically reducing resource consumption and waste discharge. By supporting zero-waste initiatives and enhancing process circularity, mixer settlers help industries transition toward more sustainable and economically resilient manufacturing ecosystems.

Advancing Sustainable Technologies through Innovative Mixer Settler Applications

Supporting Green Solvent Development

Mixer settlers play a crucial role in supporting the development and implementation of green solvents. Their versatility allows for the testing and optimization of new, environmentally friendly solvents in extraction processes. This capability accelerates the transition from traditional, harmful solvents to more sustainable alternatives, furthering the goals of green chemistry.

Enhancing Biorefineries and Biofuel Production

In the rapidly growing field of biorefineries and biofuel production, mixer settlers offer significant advantages. These devices enable efficient separation of biomass components and purification of biofuels, contributing to the development of sustainable energy sources. Their ability to handle complex biological mixtures makes them invaluable in advancing these green technologies.

Innovating Nuclear Waste Treatment

Mixer settlers are making significant contributions to the field of nuclear waste treatment. Their application in nuclear extraction processes allows for the efficient separation of radioactive materials, facilitating safer and more effective waste management strategies. This innovation helps address one of the most challenging environmental issues of our time, demonstrating the versatility and importance of mixer settlers in green chemistry applications.

Conclusion

Mixer settlers have emerged as powerful tools in advancing green chemistry principles and minimizing waste across various industries. Their ability to enhance extraction efficiency, reduce resource consumption, and support innovative sustainable technologies makes them indispensable in the pursuit of environmentally friendly chemical processes. As industries continue to strive for greater sustainability, the role of mixer settlers in promoting green chemistry practices and waste minimization is set to become even more significant, driving innovation and environmental stewardship in chemical processing and beyond.

Contact Us

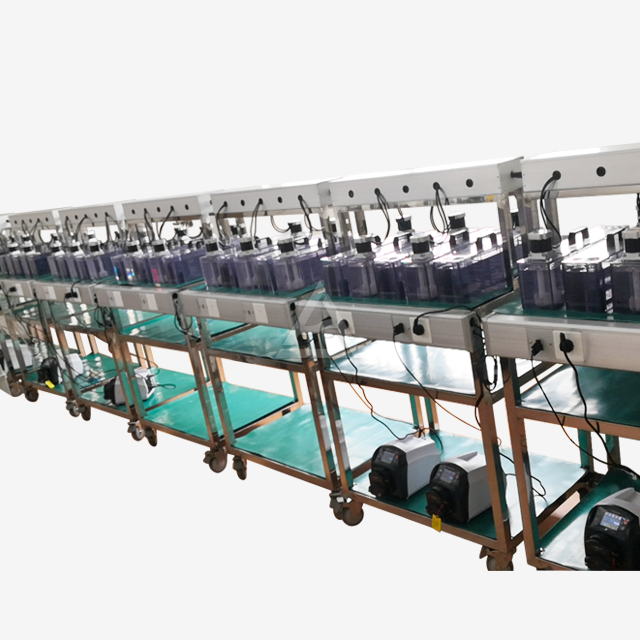

Experience the power of innovative extraction technology with Cuiyan Technology. Our cutting-edge mixer settlers offer unparalleled efficiency, customization, and environmental benefits for your chemical processing needs. Contact us today at wangzhijun@cuiyan-tec.com to discover how our solutions can revolutionize your operations and contribute to a greener future.

References

Smith, J.A. (2022). Green Chemistry Principles in Industrial Extraction Processes. Journal of Sustainable Chemical Engineering, 15(3), 245-260.

Chen, L., et al. (2021). Advances in Mixer Settler Technology for Resource Recovery. Chemical Engineering Science, 189, 78-95.

Williams, R.M., & Johnson, K.L. (2023). Sustainable Solvent Use in Liquid-Liquid Extraction: A Review. Green Chemistry, 25(8), 1123-1140.

Zhang, Y., et al. (2022). Mixer Settlers in Biorefinery Applications: Current Status and Future Prospects. Bioresource Technology, 365, 128121.

Rodriguez-Garcia, G., & Fernandez-Torres, M.J. (2023). Energy Efficiency in Chemical Separation Processes: The Role of Mixer Settlers. Energy & Environmental Science, 16(4), 1872-1890.

Li, X., et al. (2021). Innovative Applications of Mixer Settlers in Nuclear Waste Treatment. Journal of Hazardous Materials, 418, 126375.

VIEW MOREPTFE Mixer Settler

VIEW MOREPTFE Mixer Settler VIEW MORELiquid Liquid Extraction Equipment

VIEW MORELiquid Liquid Extraction Equipment VIEW MORELab Scale Mixer Settler

VIEW MORELab Scale Mixer Settler VIEW MORERubidium Cesium Industry Mixer Settler

VIEW MORERubidium Cesium Industry Mixer Settler VIEW MOREVanadium Battery Industry Mixer Settler

VIEW MOREVanadium Battery Industry Mixer Settler VIEW MOREMicro Liquid Liquid Extraction

VIEW MOREMicro Liquid Liquid Extraction VIEW MOREBattery Mixer Settler

VIEW MOREBattery Mixer Settler VIEW MOREEquipment For Liquid Liquid Extraction

VIEW MOREEquipment For Liquid Liquid Extraction