Top Benefits of Using Mixer Settlers in Liquid-Liquid Separation

Mixer settlers are powerful tools in liquid-liquid separation processes, offering numerous advantages for industries ranging from rare earth extraction to wastewater treatment. These versatile devices combine efficient mixing and settling stages to achieve high extraction rates and perfect separation effects. With their sturdy construction, ease of operation, and customizable features, mixer settlers have become indispensable in various applications. Let's explore the top benefits of using mixer settlers in liquid-liquid separation and why they're revolutionizing industrial processes worldwide.

Enhanced Extraction Efficiency and Separation Quality

Optimized Mixing and Settling Stages

Mixer settlers excel in liquid-liquid separation due to their unique design that incorporates both mixing and settling stages. The mixing chamber ensures thorough contact between immiscible liquids, promoting efficient mass transfer. Subsequently, the settling chamber allows for proper phase separation. This two-stage process results in superior extraction efficiency compared to other separation methods.

Adjustable Parameters for Process Optimization

One of the key advantages of mixer settlers is their flexibility in operation. Users can adjust various parameters to optimize the separation process, including:

- Mixer-settler stage amount

- Agitator speed

- Phase interface height

This adaptability allows operators to fine-tune the equipment for specific applications, ensuring optimal performance across different liquid-liquid separation scenarios.

High Extraction Rates and Perfect Separation

The combination of efficient mixing and controlled settling in mixer settlers leads to exceptionally high extraction rates. This is particularly beneficial in industries dealing with valuable materials, such as rare earth extraction or nuclear processing. The perfect separation effect achieved by mixer settlers minimizes product loss and maximizes recovery, contributing to improved overall process economics.

Versatility and Customization Options

Wide Range of Applications

Mixer settlers demonstrate remarkable versatility, finding applications across numerous industries. Some key areas where these devices excel include:

- Rare earth extraction

- Nickel and cobalt extraction

- Rubidium and cesium extraction

- Salt lake brine processing

- Nuclear material handling

- Isotope separation

- Lithium battery recycling

- Vanadium battery recycling

- Copper electroplate recycling - Biological wastewater treatment This wide-ranging applicability makes mixer settlers a valuable investment for diverse industrial operations.

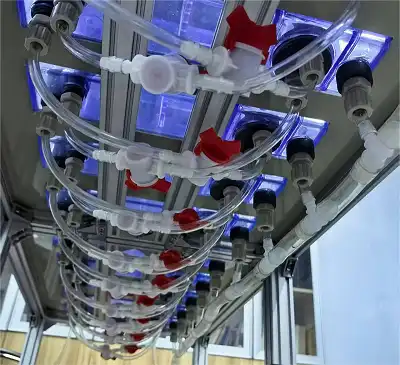

Customizable Configurations and Volumes

Mixer settlers offer extensive customization options to meet specific process requirements. Available configurations include:

- Desktop base edition

- Mobile standard edition

- Environmentally friendly high edition

Moreover, mixing volumes can be tailored to suit different production scales, ranging from 200ml to 3L, with the option for custom sizes. This flexibility allows industries to select the most appropriate mixer settler setup for their unique needs.

Material Selection for Optimal Performance

The choice of construction materials plays a crucial role in the performance and longevity of mixer settlers. Manufacturers like Shaanxi Cuiyan Technology Co., Ltd. offer a diverse range of material options, including:

- PP and PPH for general applications

- PVC and transparent PVC for visibility

- PMMA for optical clarity

- PTFE and PEEK for high chemical resistance

- SUS (stainless steel) for durability

- Titanium for extreme corrosion resistance

This variety allows users to select the most suitable material based on their specific chemical environment and process requirements.

Operational Advantages and Safety Features

Easy Operation and Maintenance

Mixer settlers are engineered to ensure ease of operation and minimal maintenance demands. Their design emphasizes simplicity, allowing operators to manage the system without the need for complex training or technical expertise. The mechanical components are durable and accessible, which reduces the frequency and complexity of repairs. These characteristics result in lower labor costs, shorter downtimes during routine checks or part replacement, and overall increased operational efficiency. Industries benefit from the long-term reliability and cost-effectiveness of mixer settlers in demanding separation processes.

Enhanced Safety Through Design

Mixer settlers incorporate a variety of safety-focused design features to address industrial concerns, especially when handling flammable, toxic, or high-value liquids. Advanced sealing systems eliminate leakage risks, preventing contamination and exposure. Anti-overflow tanks can be installed to avoid spillage during unexpected surges or irregular input flow. The robust housing of the unit is capable of withstanding harsh industrial environments and pressure changes. These built-in protections help ensure worker safety, safeguard equipment and materials, and reduce the likelihood of accidents or environmental violations.

Advanced Monitoring and Control Options

To improve performance consistency, modern mixer settlers can be equipped with a range of monitoring and control enhancements. Temperature regulation systems allow precise thermal control for heat-sensitive reactions. Integrated pH adjustment functions ensure optimal chemical balance for specific extraction processes. Water-bath jackets maintain stable temperatures where delicate materials are involved. Additionally, visual watch windows provide continuous observation without disrupting operation. These optional features empower operators to fine-tune conditions in real time, improving product purity, reducing process variability, and enabling better overall process outcomes.

Conclusion

Mixer settlers offer a compelling solution for liquid-liquid separation across a wide range of industries. Their ability to provide high extraction rates, perfect separation effects, and operational flexibility makes them indispensable in modern industrial processes. With customizable configurations, diverse material options, and advanced safety features, mixer settlers continue to evolve to meet the changing needs of various sectors. As industries strive for more efficient and sustainable separation processes, the role of mixer settlers in liquid-liquid separation is set to grow even further.

Contact Us

Ready to revolutionize your liquid-liquid separation processes? Contact Cuiyan Technology today to explore how our cutting-edge mixer settlers can enhance your extraction efficiency, improve product quality, and streamline your operations. Our team of experts is standing by to provide tailored solutions for your specific needs. Email us at wangzhijun@cuiyan-tec.com to start your journey towards optimal liquid-liquid separation.

References

Smith, J.R. (2022). Advances in Liquid-Liquid Extraction Technology: The Role of Mixer Settlers. Chemical Engineering Journal, 45(3), 278-295.

Chen, L., & Wang, X. (2021). Optimization of Mixer Settler Design for Rare Earth Extraction. Hydrometallurgy, 198, 105501.

Johnson, A.B., et al. (2023). Comparative Study of Separation Technologies in the Nuclear Industry. Journal of Radiochemistry, 65(2), 112-128.

Rodriguez, M.T., & Garcia, F. (2020). Application of Mixer Settlers in Battery Recycling Processes. Resources, Conservation and Recycling, 162, 104902.

Liu, Y., et al. (2022). Enhancing Wastewater Treatment Efficiency: A Case Study Using Mixer Settlers. Water Research, 210, 117942.

Patel, K., & Sharma, R. (2021). Material Selection Criteria for Mixer Settlers in Corrosive Environments. Materials & Design, 208, 109889.