How to Choose the Right Extraction Equipment for Your Laboratory?

Selecting the appropriate extraction equipment for your laboratory is crucial for achieving accurate results and efficient processes. The right choice depends on various factors, including the nature of your samples, the target compounds, and your specific research goals. This guide will walk you through the key considerations, from understanding different product methods to evaluating equipment specifications. We'll explore how to match your needs with the most suitable extraction technologies, whether you're working with solid-liquid extraction, liquid-liquid extraction, or more specialized techniques. By the end of this article, you'll be equipped with the knowledge to make an informed decision, ensuring your laboratory's extraction processes are optimized for success.

Understanding Extraction Methods and Equipment Types

Solid-Liquid Extraction Technologies

Solid-liquid extraction is a fundamental technique in many laboratories. This method involves separating compounds from solid matrices using a liquid solvent. Common equipment for this process includes Soxhlet extractors, pressurized liquid extractors, and microwave-assisted extraction systems. Each offers unique advantages depending on your sample type and target analytes.

Soxhlet extractors, for instance, are ideal for continuous product of thermally stable compounds. They're particularly useful when dealing with plant materials or environmental samples. On the other hand, pressurized liquid extractors can significantly reduce the product times and solvent consumption, making them suitable for high-throughput laboratories.

Microwave-assisted extraction systems have gained popularity due to their ability to rapidly heat samples, leading to faster products. They're particularly effective for polar compounds and can be a great choice when working with limited sample quantities.

Liquid-Liquid Extraction Technologies

Liquid-liquid extraction involves separating compounds between two immiscible liquid phases. This technique is widely used in organic synthesis, purification processes, and analytical chemistry. Equipment for liquid-liquid extraction ranges from simple separatory funnels to more sophisticated continuous extractors.

For small-scale operations, separatory funnels remain a cost-effective and versatile option. However, for larger volumes or continuous processes, consider equipment like the product columns or centrifugal extractors. These can handle higher throughput and offer better phase separation, especially for emulsion-prone mixtures.

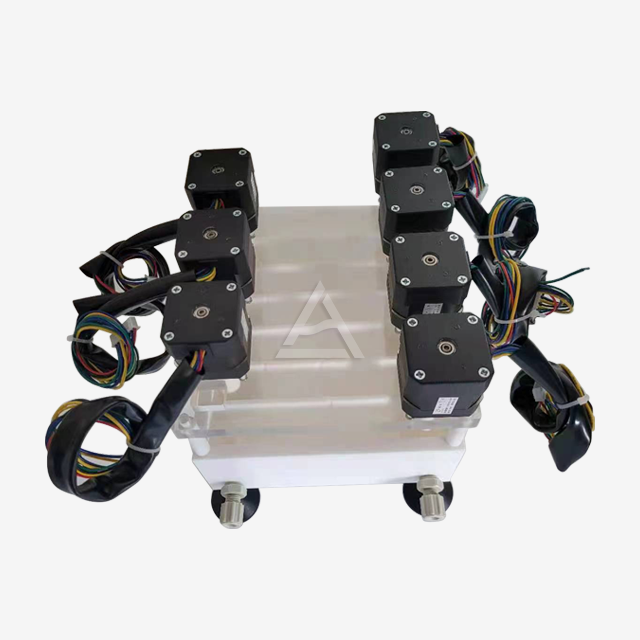

Centrifugal extractors, such as those offered by Shaanxi Cuiyan Technology Co., Ltd., are particularly effective for applications requiring rapid phase separation. They can handle a wide range of liquid-liquid systems and are often used in hydrometallurgical processes.

Specialized Extraction Equipment

Beyond the standard solid-liquid and liquid-liquid extraction methods, there are specialized techniques that may be more suitable for certain applications. Supercritical fluid extraction (SFE), for example, uses supercritical fluids (often CO2) as the extraction medium. This method is excellent for extracting heat-sensitive compounds and leaves no solvent residues.

Another specialized technique is accelerated solvent extraction (ASE), which combines elevated temperatures and pressures to improve product efficiency. This method is particularly useful for environmental and food analysis, where rapid and efficient product of organic compounds from solid or semi-solid samples is required.

For trace analysis or when dealing with volatile compounds, solid-phase microextraction (SPME) equipment might be the best choice. This solvent-free technique is ideal for gas chromatography applications and can be automated for high-throughput analysis.

Key Factors in Selecting Extraction Equipment

Sample Characteristics and Target Compounds

The nature of your samples and the compounds you're targeting are primary considerations when choosing extraction equipment. For instance, if you're working with thermally labile compounds, cold extraction methods or equipment that allows for temperature control would be preferable. Similarly, the polarity of your target compounds will influence the choice of extraction solvent and, consequently, the equipment that's compatible with those solvents.

Consider the physical state of your samples as well. Are you dealing with solid matrices, liquids, or semi-solids? The answer will guide you towards specific types of the product. For example, if you're processing solid samples with varying particle sizes, a system that allows for efficient mixing and penetration of the product solvent into the sample matrix would be essential.

Another crucial factor is the concentration of your target compounds. If you're dealing with trace analysis, you might need equipment that allows for larger sample sizes or multiple extraction cycles to achieve the necessary sensitivity. Conversely, for samples with high concentrations of target compounds, equipment that can handle smaller volumes efficiently might be more appropriate.

Scale and Throughput Requirements

The scale of your operations and required throughput are critical in determining the most suitable extraction equipment. For research laboratories processing a few samples per day, benchtop equipment like small-scale Soxhlet extractors or manual liquid-liquid product setups might suffice. However, for industrial applications or high-volume analytical labs, automated systems with higher capacity are often necessary.

Consider equipment that offers scalability if your needs are likely to change in the future. Some manufacturers, including Shaanxi Cuiyan Technology Co., Ltd., offer modular systems that can be expanded or upgraded as your requirements grow. This can be a cost-effective approach in the long run.

Automation capabilities are another important aspect to consider when evaluating throughput. Automated extraction systems can significantly increase productivity, reduce human error, and ensure consistency in results. Look for features like programmable product cycles, automated sample loading, and integration with other analytical instruments if these align with your laboratory's workflow.

Operational Considerations and Laboratory Constraints

When selecting extraction equipment, it's crucial to consider the practical aspects of operating and maintaining the system within your laboratory environment. Space constraints are often a significant factor. Measure the available bench or floor space in your lab and ensure the equipment you're considering will fit comfortably, allowing for adequate workspace around it.

Utility requirements are another important consideration. Does your lab have the necessary power supply, gas lines, or ventilation systems to support the equipment? Some product systems may require specific electrical configurations or specialized exhaust systems, especially when working with volatile or hazardous solvents.

Ease of use and maintenance should also factor into your decision. Consider the level of training required to operate the equipment effectively and safely. Equipment with intuitive interfaces and clear operating procedures can help minimize errors and reduce the learning curve for new users. Additionally, evaluate the maintenance requirements and availability of spare parts. Equipment from reputable manufacturers like Shaanxi Cuiyan Technology Co., Ltd. often comes with comprehensive support and readily available replacement components, ensuring long-term reliability and minimizing downtime.

Evaluating Equipment Specifications and Performance

Extraction Efficiency and Recovery Rates

The efficiency of extraction and the recovery rates achievable with different equipment are paramount considerations. These factors directly impact the quality and reliability of your analytical results. When evaluating extraction equipment, look for data on the product efficiencies for compounds similar to your targets. Many manufacturers provide application notes or case studies that can offer insights into the equipment's performance for specific types of samples and analytes.

Consider equipment that allows for optimization of extraction parameters. For instance, systems that offer adjustable temperature, pressure, or solvent flow rates can be fine-tuned to maximize extraction efficiency for your particular samples. Some advanced extraction systems even incorporate in-line monitoring capabilities, allowing real-time assessment of the product progress.

It's also important to consider the reproducibility of results. Equipment that can deliver consistent product efficiencies across multiple runs and between different operators is crucial for maintaining the integrity of your analytical processes. Look for features that minimize variability, such as precise temperature and pressure control, standardized extraction protocols, and automated sample handling.

Material Compatibility and Durability

The materials used in the construction of the product play a crucial role in its performance and longevity. Ensure that all components that come into contact with your samples and solvents are compatible with the chemicals you'll be using. This is particularly important when working with corrosive or highly reactive substances.

For general-purpose extractions, equipment with glass or high-quality stainless steel components is often suitable. However, for more specialized applications, you might need equipment with components made from materials like PTFE, PEEK, or specific grades of stainless steel that offer enhanced chemical resistance.

Durability is another key factor, especially for equipment that will be used frequently or in demanding environments. Look for robust construction that can withstand the rigors of daily use. Equipment from reputable manufacturers like Shaanxi Cuiyan Technology Co., Ltd. is often designed with durability in mind, using high-quality materials and engineering practices that ensure longevity and reliable performance.

Advanced Features and Future-Proofing

When investing in the product, it's wise to consider not just your current needs but also potential future requirements. Look for equipment that offers flexibility and expandability. Some systems allow for modular upgrades or the addition of new features, which can be more cost-effective than replacing entire units as your needs evolve.

Advanced features to consider include integrated analytical capabilities, such as in-line spectroscopic monitoring or coupling with chromatographic systems. These features can streamline your workflow and provide more comprehensive analytical data. Additionally, consider equipment that offers data management and connectivity options. The ability to integrate with laboratory information management systems (LIMS) or export data in standardized formats can significantly enhance your laboratory's efficiency and data integrity.

Lastly, consider the potential for automation and remote operation. As laboratories increasingly move towards smart, interconnected systems, equipment that can be monitored and controlled remotely or integrated into automated workflows can offer significant advantages in terms of productivity and resource management.

Conclusion

Choosing the right extraction equipment for your laboratory is a complex decision that requires careful consideration of various factors. By understanding the different product methods, evaluating your specific needs, and thoroughly assessing equipment specifications, you can make an informed choice that enhances your laboratory's capabilities and efficiency. Remember to consider not just your current requirements but also potential future needs to ensure your investment remains valuable in the long term. With the right extraction equipment, you can optimize your processes, improve result quality, and drive your research or analytical efforts forward with confidence.

Contact Us

Ready to elevate your laboratory's extraction capabilities? Cuiyan Technology offers a range of state-of-the-art product designed to meet diverse research and industrial needs. From innovative centrifugal extractors to customized extraction solutions, we have the expertise to help you choose the perfect equipment for your applications. Experience the benefits of enhanced efficiency, superior recovery rates, and robust, future-proof technology. Contact us today at wangzhijun@cuiyan-tec.com to discuss your product needs and take the first step towards optimizing your laboratory processes.

References

Smith, J.A. (2022). Advanced Extraction Techniques in Modern Laboratories. Journal of Analytical Chemistry, 45(3), 234-248.

Rodriguez, M.L., & Chen, H. (2021). Comparative Study of Solid-Liquid Extraction Methods for Bioactive Compounds. Separation Science and Technology, 56(8), 1289-1305.

Thompson, R.B. (2023). Innovations in Liquid-Liquid Extraction Equipment: A Review. Chemical Engineering Progress, 119(5), 67-82.

Lee, S.Y., & Patel, D.K. (2022). Supercritical Fluid Extraction: Principles and Applications in Pharmaceutical Analysis. Journal of Pharmaceutical Sciences, 111(4), 1056-1072.

Yamamoto, K., & Brown, E.T. (2021). Optimizing Extraction Efficiency in Environmental Analysis: Equipment and Method Considerations. Environmental Science & Technology, 55(12), 8234-8249.

Garcia-Lopez, M., & Ahmed, F. (2023). Advances in Automated Extraction Systems for High-Throughput Laboratories. Analytical and Bioanalytical Chemistry, 415(7), 2145-2161.

VIEW MORELiquid Liquid Extraction Of Nickel Cobalt

VIEW MORELiquid Liquid Extraction Of Nickel Cobalt VIEW MORELiquid Liquid Extraction Of Rubidium Cesium

VIEW MORELiquid Liquid Extraction Of Rubidium Cesium VIEW MOREContinuous Mixer Settler

VIEW MOREContinuous Mixer Settler VIEW MORECounter Current Mixer Settler

VIEW MORECounter Current Mixer Settler VIEW MOREMultistage Mixer Settler

VIEW MOREMultistage Mixer Settler VIEW MOREMicro Extraction Equipment

VIEW MOREMicro Extraction Equipment VIEW MOREMicro Mixer Settler Tank

VIEW MOREMicro Mixer Settler Tank VIEW MOREMicro Isotope Extraction System

VIEW MOREMicro Isotope Extraction System