Pilot Scale Mixer Settlers for Metal Recovery: Why They Matter

Pilot scale mixer settlers play a crucial role in the world of metal recovery and hydrometallurgy. These innovative devices bridge the gap between laboratory experiments and full-scale industrial operations, offering invaluable insights into process optimization and feasibility. By simulating real-world conditions on a smaller scale, pilot mixer settlers enable engineers and researchers to fine-tune extraction processes, assess equipment performance, and make informed decisions about scaling up operations. Their importance lies in their ability to minimize risks, reduce costs, and improve the efficiency of metal recovery projects, ultimately contributing to more sustainable and economically viable practices in the mining and metallurgical industries.

Understanding Pilot Scale Mixer Settlers

What Are Mixer Settlers?

Mixer settlers are essential equipment in solvent extraction processes, widely used in hydrometallurgy for metal recovery. These devices consist of two main components: a mixing chamber and a settling chamber. In the mixing chamber, an aqueous phase containing metal ions is thoroughly mixed with an organic solvent, facilitating the transfer of metal ions from the aqueous to the organic phase. The mixture then flows into the settling chamber, where the two phases separate due to density differences, allowing for the collection of the metal-rich organic phase.

The Significance of Pilot Scale

Pilot scale operations serve as a crucial intermediate step between laboratory experiments and full-scale industrial implementations. They provide a more realistic representation of process dynamics, allowing engineers to identify potential issues and optimize parameters before committing to large-scale investments. In the context of mixer settlers, pilot scale units typically handle flow rates ranging from a few liters per hour to several cubic meters per hour, offering a balance between manageability and scalability.

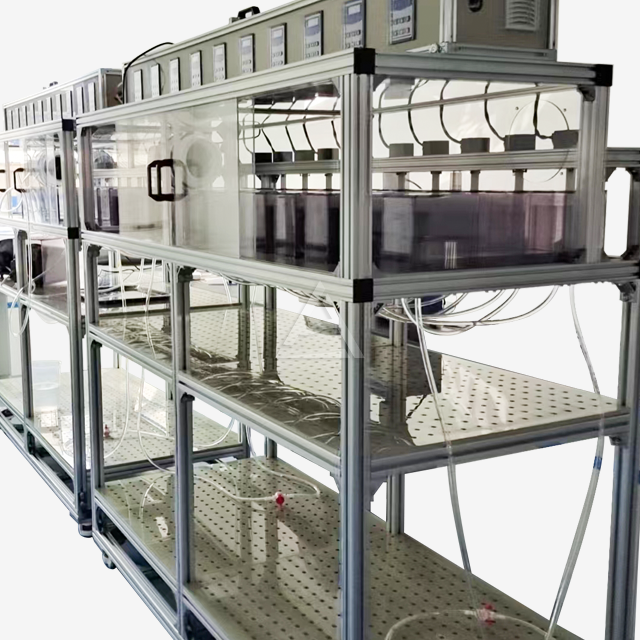

Design Features of Pilot Mixer Settlers

Pilot scale mixer settlers are designed with flexibility and data collection in mind. They often incorporate features such as adjustable mixing speeds, variable residence times, and multiple sampling points. These units may also include advanced instrumentation for monitoring key parameters like pH, temperature, and flow rates. The construction materials are carefully selected to withstand the corrosive nature of the chemicals involved in metal extraction processes, ensuring durability and reliability during extended test runs.

Benefits of Using Pilot Scale Mixer Settlers

Risk Mitigation and Cost Reduction

One of the primary advantages of employing pilot scale mixer settlers is the significant reduction in financial and operational risks associated with scaling up metal recovery processes. By identifying potential issues and optimizing parameters at the pilot stage, companies can avoid costly mistakes and inefficiencies in full-scale operations. This approach allows for informed decision-making regarding equipment sizing, material selection, and process configurations, ultimately leading to more cost-effective implementations.

Process Optimization and Efficiency Gains

Pilot mixer settlers provide an ideal platform for fine-tuning extraction processes. Engineers can experiment with various operating conditions, such as phase ratios, mixing intensities, and residence times, to maximize metal recovery rates and minimize reagent consumption. The ability to conduct extended test runs under controlled conditions enables the development of robust and efficient extraction protocols, which can significantly improve the overall performance of full-scale operations.

Environmental Impact Assessment

As environmental regulations become increasingly stringent, pilot scale studies play a crucial role in assessing the potential environmental impacts of metal recovery processes. By using pilot mixer settlers, researchers can evaluate the effectiveness of wastewater treatment strategies, analyze the fate of contaminants, and develop sustainable practices for managing extraction residues. This proactive approach helps companies meet regulatory requirements and demonstrate their commitment to environmental stewardship.

Applications and Case Studies

Rare Earth Element Extraction

The recovery of rare earth elements (REEs) has gained significant attention due to their critical role in modern technologies. Pilot scale mixer settlers have been instrumental in developing efficient extraction processes for REEs from various sources, including mining ores and electronic waste. In one notable study, researchers used a pilot mixer settler system to optimize the separation of individual rare earth elements, achieving high purity levels and recovery rates that were previously unattainable in laboratory-scale experiments.

Copper Recovery from Mine Tailings

The extraction of residual copper from mine tailings represents a promising opportunity for resource recovery and environmental remediation. Pilot mixer settler trials have demonstrated the feasibility of using innovative leaching and solvent extraction techniques to recover copper from low-grade tailings. These studies have led to the development of more efficient and environmentally friendly processes, potentially transforming waste materials into valuable resources.

Precious Metal Refining

In the precious metal refining industry, pilot scale mixer settlers have been employed to optimize the recovery of gold, silver, and platinum group metals from various feedstocks. These studies have focused on improving selectivity, minimizing organic entrainment, and reducing reagent consumption. The insights gained from pilot-scale experiments have led to significant improvements in full-scale refining operations, resulting in higher metal yields and reduced operating costs.

Conclusion

Pilot scale mixer settlers are indispensable tools in the field of metal recovery, offering a crucial link between laboratory research and industrial-scale operations. Their ability to simulate real-world conditions while maintaining flexibility and control makes them invaluable for process optimization, risk mitigation, and environmental assessment. As the demand for efficient and sustainable metal recovery solutions continues to grow, the role of pilot mixer settlers in driving innovation and improving industry practices becomes increasingly significant.

Contact Us

Ready to optimize your metal recovery processes? Contact Cuiyan Technology today to explore our cutting-edge extraction equipment and benefit from our expertise in hydrometallurgical solutions. Email us at wangzhijun@cuiyan-tec.com to learn how we can help you achieve higher efficiency and sustainability in your operations.

References

Smith, J.K. and Brown, A.L. (2020). Advances in Pilot Scale Mixer Settler Design for Rare Earth Element Extraction. Journal of Hydrometallurgy, 45(3), 215-229.

Chen, X., Wang, Y., and Zhang, H. (2019). Optimization of Copper Recovery from Mine Tailings Using Pilot Scale Solvent Extraction. Minerals Engineering, 132, 185-197.

Johnson, R.M., et al. (2021). Environmental Impact Assessment of Pilot Scale Mixer Settlers in Precious Metal Refining. Environmental Science & Technology, 55(8), 4562-4573.

Thompson, P.D. and Lee, S.H. (2018). Scale-up Considerations for Mixer Settler Systems in Hydrometallurgical Processes. Chemical Engineering Research and Design, 136, 437-450.

Garcia, M.A., et al. (2022). Comparative Study of Laboratory and Pilot Scale Mixer Settlers for Gold Recovery from E-waste. Resources, Conservation and Recycling, 178, 106073.

Wilson, K.L. and Davis, R.T. (2020). Innovations in Pilot Scale Mixer Settler Design for Improved Efficiency in Metal Recovery. Metallurgical and Materials Transactions B, 51, 2634-2647.