Understanding PTFE Mixer Settlers: Features and Advantages

The Science Behind PTFE Material

PTFE, commonly known as Teflon, is a synthetic fluoropolymer of tetrafluoroethylene. Its unique molecular structure gives it exceptional chemical resistance, making it ideal for use in aggressive environments. PTFE's carbon-fluorine bonds are among the strongest in organic chemistry, resulting in a material that's virtually inert to most chemicals and solvents. This inertness extends to both strong acids and alkalis, allowing PTFE mixer settlers to handle a wide range of corrosive substances without degradation.

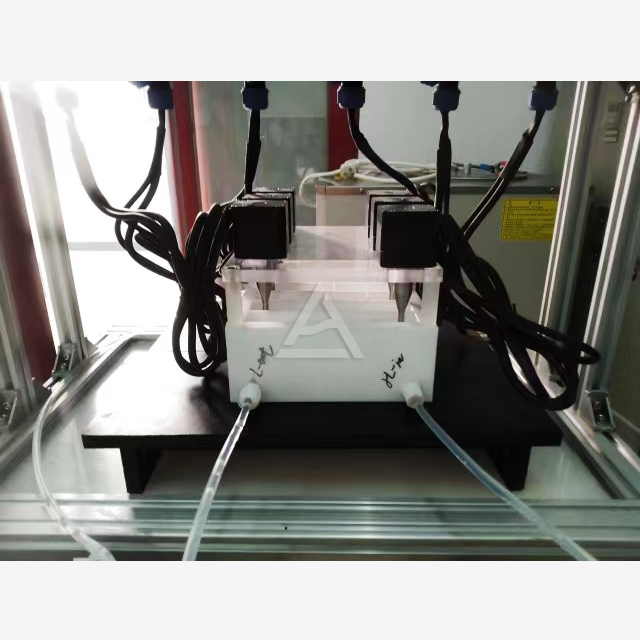

Design Principles of PTFE Mixer Settlers

PTFE mixer settlers are engineered to maximize separation efficiency while leveraging the material's inherent properties. The design typically includes a mixing chamber where immiscible liquids are thoroughly combined, followed by a settling zone where gravity separation occurs. The use of PTFE in critical components ensures that the equipment maintains its integrity even when exposed to harsh chemicals. Additionally, the non-stick nature of PTFE prevents buildup and fouling, contributing to consistent performance and reduced maintenance needs.

Comparative Advantages over Traditional Materials

When compared to mixer settlers made from other materials such as stainless steel or glass, PTFE offers distinct advantages. Its superior chemical resistance eliminates the need for expensive alloys in many applications. PTFE's low friction coefficient reduces energy consumption during operation, while its non-wetting properties facilitate clean separation of phases. Moreover, the material's excellent thermal stability allows for operation across a wide temperature range, enhancing versatility in various processes.

Applications and Industries Benefiting from PTFE Mixer Settlers

Petrochemical Processing

In the petrochemical industry, PTFE mixer settlers play a crucial role in processes such as solvent extraction and acid treatment. Their ability to withstand aggressive chemicals like sulfuric acid and hydrochloric acid makes them invaluable in refining operations. For instance, in the production of high-purity aromatics, PTFE mixer settlers can handle the corrosive extraction solvents used to separate desired compounds from complex hydrocarbon mixtures. This resilience translates to longer equipment life and reduced downtime, ultimately improving operational efficiency and cost-effectiveness.

Pharmaceutical Manufacturing

The pharmaceutical sector benefits greatly from the use of PTFE mixer settlers, particularly in the production of active pharmaceutical ingredients (APIs). These devices are essential in liquid-liquid extraction processes where precise separation of organic and aqueous phases is critical. The inert nature of PTFE ensures that no contamination occurs during the extraction process, maintaining the purity of pharmaceutical compounds. Furthermore, the ease of cleaning and sterilization associated with PTFE surfaces aligns well with the stringent hygiene requirements of the industry.

Metal Recovery and Purification

In hydrometallurgical processes, PTFE mixer settlers excel in the recovery and purification of metals from ores and waste streams. Their resistance to both acidic leaching solutions and basic precipitating agents makes them versatile tools in metal extraction circuits. For example, in the recovery of precious metals like gold and silver, PTFE mixer settlers can handle the cyanide solutions used in leaching without risk of equipment degradation. This capability extends to the treatment of electronic waste and other metal-rich secondary sources, supporting sustainable resource management practices.

Optimizing Performance: Best Practices for PTFE Mixer Settler Operation

Proper Sizing and Configuration

To maximize the efficiency of PTFE mixer settlers, proper sizing and configuration are essential. The equipment should be designed to accommodate the specific flow rates and residence times required for optimal separation. Factors such as the interfacial tension between phases, density differences, and viscosity of the liquids involved must be considered. Customization options, including adjustable weirs and baffles, can fine-tune the separation process. Consulting with experienced manufacturers like Xi'an Plansee Chemical Industry Science&Technology Co., Ltd. can ensure that the mixer settler is tailored to your specific application requirements.

Maintenance and Cleaning Protocols

While PTFE mixer settlers are known for their low maintenance requirements, implementing proper care routines can further extend their operational life. Regular inspection of seals, connections, and moving parts is recommended to prevent potential leaks or performance issues. Cleaning protocols should be established based on the specific chemicals and contaminants involved in the process. The non-stick nature of PTFE often allows for simple flushing or wiping procedures, but more thorough cleaning may be necessary for certain applications. Adhering to manufacturer guidelines for maintenance and cleaning will ensure consistent performance and longevity of the equipment.

Process Optimization Techniques

To achieve peak performance from PTFE mixer settlers, various optimization techniques can be employed. Monitoring and adjusting parameters such as mixing intensity, phase ratio, and flow rates can significantly impact separation efficiency. Implementation of inline analytics for real-time monitoring of phase composition can enable dynamic process control. Additionally, exploring the use of coalescers or other phase-enhancing devices in conjunction with PTFE mixer settlers may further improve separation outcomes. Continuous improvement through data analysis and process refinement will lead to optimal utilization of these versatile separation devices.

Conclusion

PTFE mixer settlers represent a significant advancement in liquid-liquid extraction technology, offering unparalleled resistance to strong acids and alkalis. Their unique properties make them indispensable in industries where corrosive environments are the norm. By providing efficient separation capabilities while maintaining chemical inertness, these devices enhance process reliability and reduce operational costs. As industries continue to seek more durable and efficient solutions, PTFE mixer settlers stand out as a prime example of how innovative materials can revolutionize chemical processing and separation techniques.

Contact Us

Ready to revolutionize your separation processes? Cuiyan Technology offers cutting-edge PTFE mixer settlers designed for optimal performance in harsh chemical environments. Experience the benefits of increased efficiency, reduced maintenance, and extended equipment life. Contact us at wangzhijun@cuiyan-tec.com to discuss how our PTFE mixer settlers can transform your operations today!