The mixer settler plays a pivotal role in liquid-liquid extraction processes, balancing the intricate phases of mixing and settling for optimal mass transfer and phase separation. This equipment integrates solvent extraction principles, ensuring high extraction efficiency and minimal emulsification. With customizable configurations tailored to various throughput demands and materials compatible with diverse chemical environments, mixer settlers enable precision, compliance, and scalability across multiple industries. Whether you seek improved mixing efficiency or robust phase interface control, understanding mixer settler specifications and applications empowers informed procurement decisions.

Understanding Mixer Settler Configurations and Specifications

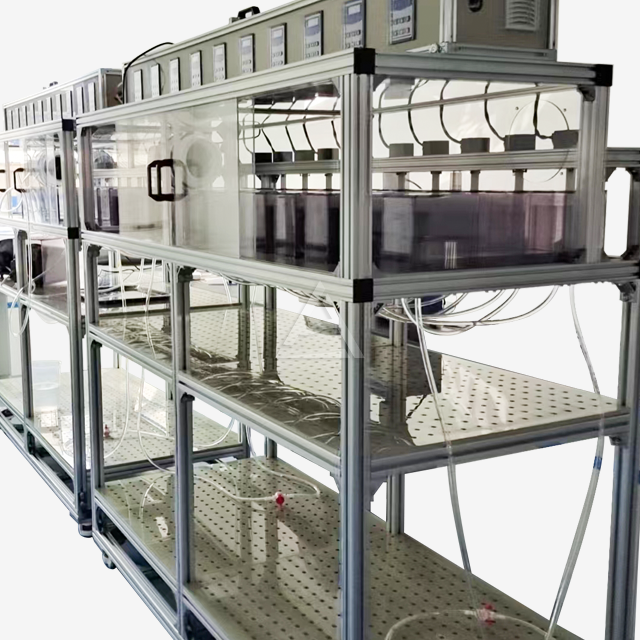

Mixer settlers come in several configurations to fit distinct operational needs. Shaanxi Cuiyan Technology Co., Ltd. offers three main editions: a desktop base edition ideal for laboratory and pilot-scale tests; a mobile standard edition providing ease of relocation with stable performance; and an environmentally friendly high edition emphasizing energy-saving features and corrosion resistance. Mixing volumes range extensively, from 200ml for research to 3L or custom sizes for industrial throughput, ensuring adaptability.

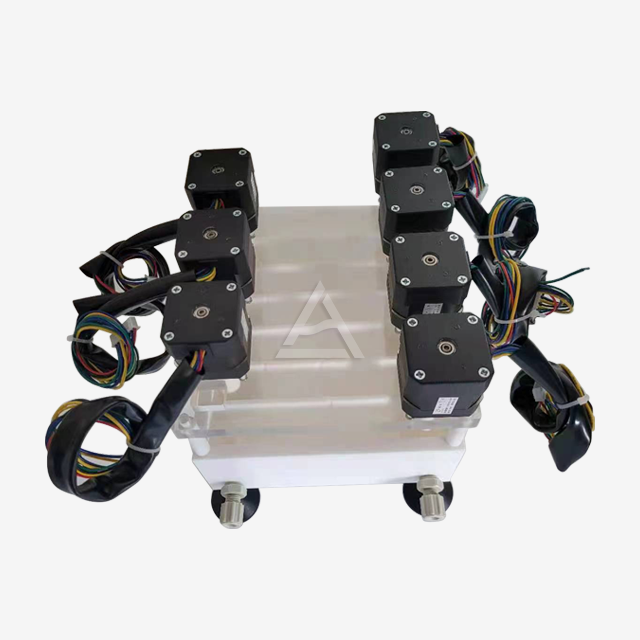

Plate thickness varies between 5mm to 10mm, delivering structural integrity and resistance to wear. Materials selection offers versatility - options like polypropylene (PP), polyphenylene (PPH), polyvinyl chloride (PVC), transparent PVC, polymethyl methacrylate (PMMA), polytetrafluoroethylene (PTFE), polyether ether ketone (PEEK), stainless steel (SUS), and titanium (Ti) cater to different chemical compatibilities and visibility preferences. Production methods utilize welding, bonding, bending, injection molding, and integral forming to optimize durability and prevent leaks.

Optional functions enhance process control: temperature and pH adjustment devices regulate reaction conditions; water-bath jackets provide thermal stability; anti-overflow tanks and watch windows improve safety and monitoring during continuous operations. These parameters collectively impact hydrodynamics, agitation effectiveness, and settling time, crucial to maintaining stable interfacial tension and preventing emulsification.

Applications Across Diverse Industries

The versatility of mixer settlers makes them indispensable in sectors demanding precision liquid-liquid extraction and phase separation. In pharmaceuticals and nutraceuticals, they assure botanical extract purity under GMP-compliant conditions, preserving delicate bioactive compounds through gentle yet efficient solvent extraction. Food and beverage industries benefit from food-grade materials and high throughput capabilities to isolate essential oils, natural colors, and flavors without compromising quality.

Cosmetics and personal care manufacturers rely on gentle agitation methods, such as CO2 extraction compatibility, to maintain the integrity of skincare ingredients and perfume distillates. For chemical and industrial applications, robust mixer settlers accommodate large volumes, supporting the recovery of critical elements like lithium, cobalt, and rare earth metals through countercurrent flow designs that enhance extraction efficiency and solvent recycling.

Examples include rare earth nuclei purification (neodymium, dysprosium), lithium battery recycling with precise cobalt-lithium recovery, nuclear fuel processing through uranium/plutonium separation, and industrial wastewater treatment by removing heavy metals such as copper and zinc. The ability to customize agitator speed, stage count, and phase interface height enables tailored mass transfer and improved coalescence for complex separations.

Essential Features Driving Performance and Reliability

Key advantages of high-quality mixer settlers include a high extraction rate and flawless phase separation, achieved through design features like patented baffle structures that eliminate bubbles and stabilize the interface. Zero-leak designs with seamless welds and PTFE seals mitigate contamination risks, a critical factor for pharmaceutical and food-grade operations.

Adjustable parameters - mixing speed from 100 to 800 RPM, settler stage number, and phase interface height - allow fine-tuning of the separation process according to the solute distribution characteristics. Sensor integration monitoring temperature, pH, and liquid levels facilitates real-time control, enhancing product consistency and enabling continuous operation. The modular design supports scalable solutions while reducing energy consumption by up to 20% compared to conventional equipment.

How Mixer Settlers Operate: The Science Behind Efficient Separation

At the heart of mixer settler technology is a two-stage process balancing mixing and settling. The agitator disperses one phase into another, promoting interfacial contact and mass transfer while maintaining controlled turbulence to avoid excessive emulsification. The mixing zone ensures thorough dispersion of solutes within the solvent matrix, crucial for efficient extraction.

The settling zone then allows gravitational forces to separate immiscible liquids; strategically adjustable weirs guide phase interface height to maximize separation and coalescence. Continuous flow setups, with stacked modular stages, permit sequential extractions within a compact footprint, ideal for industrial-scale chemical engineering and solvent recovery applications. This setup contrasts with batch processing by enhancing throughput, process stability, and operational consistency.

Buyer's Tips on Selecting the Ideal Mixer Settler System

Purchasing a mixer settler requires matching equipment capabilities with specific process requirements. Evaluate mixing volume to align with throughput needs—desktop units serve development and pilot studies, while larger systems handle full-scale production. Material compatibility must match solvent and solute chemistry to prevent corrosion or contamination; for acidic or alkaline media, PTFE and SUS316L offer superior resistance.

Consider optional functions like temperature and pH control to maintain process parameters critical for sensitive compounds in pharmaceuticals and cosmetics. Customizability in agitator speed and settler stage number affords operational flexibility, accommodating process changes or scale-up. Zero-leak designs and compliance with standards such as ASME, ISO, and REACH ensure regulatory adherence for cross-border ventures.

Finally, factor in maintenance ease, including cleaning protocols (e.g., deionized water rinses) and seal replacement schedules, to maximize equipment lifespan and prevent downtime.

Shaanxi Cuiyan Technology Co., Ltd: Trusted Mixer Settler Manufacturer & Supplier

Since 2012, Shaanxi Cuiyan Technology Co., Ltd has thrived at the intersection of innovation and industrial reliability. Our engineering team, exceeding 37 experts, has developed over 100 patents in extraction technologies, making us a global leader in designing and manufacturing mixer settlers. Our expertise spans rare earth extraction, lithium battery recycling, nuclear fuel processing, and more.

We integrate automation, corrosion-resistant materials, and modular designs into all equipment, providing customers with energy-efficient, scalable solutions that adhere to stringent quality and environmental standards. Our comprehensive process knowledge extends beyond equipment, incorporating hydrometallurgical line design and customized extraction methods to address challenging industrial waste streams like electroplating sludge and precious metal recovery.

Choosing Shaanxi Cuiyan means partnering with a company driven by precision, compliance, innovation, and deep industry experience ready to elevate your separation processes effectively.

Conclusion

Embracing mixer settler technology transforms complex liquid-liquid separations into streamlined, efficient operations. By understanding equipment configurations, materials, and process dynamics, industries from pharmaceuticals to chemical manufacturing can optimize extraction performance and scalability. Shaanxi Cuiyan Technology's commitment to innovation, quality, and customization ensures your investment yields lasting, high-purity results. Reliable phase separation, perfect phase interface control, and operational flexibility make mixer settlers indispensable tools in modern chemical engineering workflows. Begin your journey toward enhanced separation with a trusted partner specializing in advanced extraction solutions.

Where to Buy Mixer Settler?

Discover top-tier mixer settler systems tailored to your industry at Shaanxi Cuiyan Technology Co., Ltd. Our offerings span customizable volumes, advanced materials, and state-of-the-art process control devices. Whether your priority is GMP compliance for botanical extracts or heavy-duty solvent recovery for industrial applications, we provide solutions crafted with precision and reliability. To inquire about specifications, pricing, or customization, contact us at wangzhijun@cuiyan-tec.com.

References

Seader, J. D., Henley, E. J., & Roper, D. K. (2011). Separation Process Principles. Wiley.

Perry, R. H., & Green, D. W. (2008). Perry’s Chemical Engineers’ Handbook. McGraw-Hill Education.

Kisters, T. (2008). Liquid-Liquid Extraction: Fundamentals and Applications. Elsevier.

King, C. J. (1980). Separation Processes. McGraw-Hill.

Geankoplis, C. J. (2003). Transport Processes and Separation Process Principles. Prentice Hall.

Gupta, A., & Lee, J. M. (2018). Advances in Solvent Extraction for Chemical Engineering. Springer.