A mixer settler is an essential apparatus in various industrial processes, enabling efficient liquid-liquid extraction through simultaneous mixing and settling stages. Primarily designed for seamless phase transfer and high purity separations, mixer settlers optimize the chemical process by ensuring excellent mass transfer and phase disengagement. This practical guide introduces key operational considerations, customization options, and maintenance strategies that enhance throughput and extraction efficiency, particularly valuable for industries like pharmaceuticals, food & beverage, cosmetics, and chemical manufacturing.

Understanding Mixer Settlers: Core Components and Working Principles

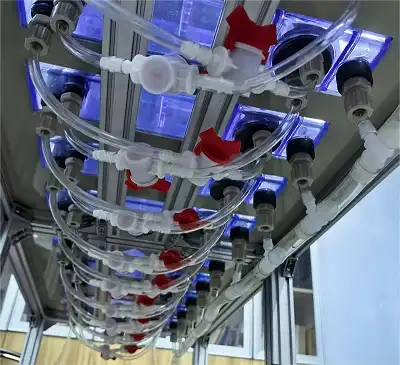

Mixer settlers operate by combining two immiscible liquid phases - typically an organic solvent and an aqueous solution - in the mixing chamber. This promotes intimate contact and efficient diffusion of solutes across the interface. Upon agitation, emulsions form to increase interfacial area and improve mass transfer rates. Subsequently, the liquid mixture moves into the settler section, where gravitational forces and interfacial tension enable phase separation. The design of mixer settlers often incorporates adjustable weirs and baffles that regulate settling effectiveness and prevent secondary emulsions or flooding. The hydrodynamics within these units influence extraction efficiency, phase clarity, and throughput capacity, all crucial for precision-driven applications.

Configuring Your Mixer Settler: Tailoring for Precision and Compliance

Equipment customization directly impacts extraction outcomes and regulatory compliance, especially in high-stakes fields such as botanical extract purification or nuclear material separation. Shaanxi Cuiyan Technology Co., Ltd offers versatile configurations including desktop base, mobile standard, and environmentally friendly high editions. Mixing volumes vary from 200ml to 3L or tailored specifications, accommodating batch or continuous operation needs. Material selections range from corrosion-resistant PTFE and SUS316L stainless steel to transparent PMMA, ensuring both chemical compatibility and process visualization. Adjustable plate thicknesses (5mm to 10mm) and multiple fabrication methods deliver robust, leak-proof units. Optional features like temperature control, pH adjustment, and anti-overflow devices boost operational precision vital for GMP-compliant extractions.

Optimizing Operation: Enhancing Extraction Efficiency and Stability

Successful mixer settler operation hinges on controlled agitation speed, precise phase interface management, and carefully staged extraction. Adjustable agitator speeds spanning 100 to 800 RPM permit fine-tuning of hydrodynamic conditions that govern emulsion formation and coalescence rates. Proper calibration of phase interface heights prevents entrainment and maximizes separation effectiveness. Modular stage arrangements allow multi-step extraction sequences within compact footprints, accommodating complex purification workflows. Real-time sensor integration for pH, temperature, and liquid levels facilitates responsive control and enhances reproducibility. Implementing patented baffle designs further mitigates bubbling and vortex formation, ensuring consistent flow patterns and reducing contamination risk.

Maintenance Best Practices: Ensuring Longevity and Operational Excellence

Routine care sustains the high extraction rates and impeccable separation quality that shell stringent regulatory demands. Post-operation cleaning with deionized water removes residual solvents and reagents, preventing fouling and cross-contamination. Inspect seals annually for wear, especially PTFE components that guarantee zero leakage. Calibration of control instruments must align with process parameters to maintain compliance and efficiency. Welding joints and molded structures designed by Shaanxi Cuiyan minimize mechanical stress points, prolonging equipment lifespan. Training operators in setup, including vertical or horizontal assembly, ensures optimal spatial utilization without compromising fluid dynamics. These protocols secure uninterrupted production in critical sectors from pharmaceuticals to battery recycling.

Diverse Industrial Applications: From Rare Earths to Wastewater Treatment

Mixer settlers excel across a spectrum of complex extraction challenges. In rare earth industry workflows, selective separation of neodymium and dysprosium uses solvent extraction cycles that attain purity levels essential for electronics and clean energy technologies. Battery recycling leverages these systems to recover lithium and cobalt, reducing environmental impact and resource dependency. Nuclear extraction processes demand flawless isolation of uranium and plutonium, where mixer settlers manage radionuclide partitioning with stringent safety protocols. Additionally, chemical plants implement them to reclaim heavy metals like copper and zinc from wastewater, safeguarding ecosystems by lowering contaminant loads through chemical precipitation and ion exchange. Versatility in scale and configuration suits both experimental R&D and large-scale production.

Why Shaanxi Cuiyan Technology Co., Ltd Stands Out for Mixer Settler Solutions?

Since 2012, Shaanxi Cuiyan Technology Co., Ltd has led innovation in extraction equipment, combining 37+ industry experts and over 100 patents to deliver cutting-edge technology. Their mixer settler systems boast a zero-leak design utilizing seamless welding and PTFE seals, ensuring uncontaminated processes aligned with ASME, ISO, and REACH standards. Energy-efficient modular structures reduce consumption by up to 20%, while the ability to customize agitation profiles, stage counts, and material compositions tailors solutions for client-specific demands. Rich experience in hydrometallurgy and clean processing of metal-laden wastes reinforces their credibility. Clients benefit from precision-engineered, scalable equipment supported by comprehensive customer service and process development expertise.

Conclusion

Mastering the operation of mixer settler systems unlocks superior phase separation and extraction efficiency crucial for high-purity applications. Customizable features, precise control mechanisms, and robust construction contribute to process reliability and regulatory compliance across industries. Shaanxi Cuiyan Technology Co., Ltd offers expertly engineered mixer settlers that meet evolving industrial needs, combining innovation with proven performance. Embracing best practices in setup, operation, and maintenance fosters sustainable, high-throughput workflows, making these systems an indispensable asset in modern chemical and biological extraction technologies.

Where to Buy Mixer Settler?

Looking to invest in top-tier mixer settler equipment? Shaanxi Cuiyan Technology Co., Ltd provides advanced, customizable mixer settlers backed by years of industry expertise and comprehensive support. Their products address diverse industrial extraction demands - from pharmaceutical botanical purification to industrial metal recovery. Interested parties can inquire directly by contacting us at wangzhijun@cuiyan-tec.com.

References

K. E. Torrance and M. A. McBride, "Liquid-Liquid Extraction: Principles and Practice," Journal of Chemical Engineering, vol. 89, no. 3, pp. 345–360, 2020.

M. B. Cole et al., "Phase Separation Dynamics in Mixer Settler Systems," Separation Science and Technology, vol. 54, no. 8, pp. 1405–1415, 2019.

J. L. Smith and D. K. Johnson, "Advanced Chemical Separation Techniques for Rare Earth Metals," Hydrometallurgy Review, vol. 103, pp. 112–124, 2021.

C. H. Lee et al., "Optimization of Solvent Extraction Parameters Using Mixer Settlers in Battery Recycling," Journal of Sustainable Chemistry, vol. 72, no. 2, pp. 98–107, 2022.

A. R. Gupta, "Hydrodynamics and Interfacial Tension Effects in Mixer Settler Equipment," Industrial & Engineering Chemistry Research, vol. 58, no. 14, pp. 5890–5899, 2019.

P. J. Thomas, "Process Control and Automation in Liquid-Liquid Extraction," Automation in Chemical Engineering, vol. 47, pp. 321–335, 2018.