Micro Liquid Liquid Extractor

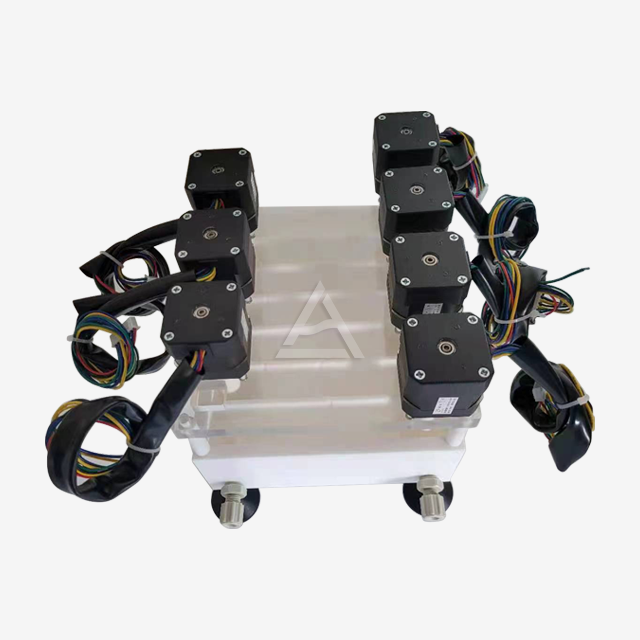

Configuration:simple desktop platform edition

Mixing volumn: 20ml, 25ml, 50ml, 80ml, 100ml, 125ml or customized

Wall thickness:8mm,10mm,12mm

Material: PMMA,PTFE,PEEK,Ti

Production process: CNC integral forming

Matching equipment: Optional micro injection pump

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable mixer-settler stage amount, adjustable agitator speed;Highly customizable

Application:nuclear extraction industry;isotope extraction industry;solvent extraction agent industry

- Product Description

Shaanxi Cuiyan: Your Trusted Micro Liquid Liquid Extractor Manufacturer & Supplier

Since 2012, Shaanxi Cuiyan Technology Co., Ltd has delivered cutting-edge extraction solutions to 300+ global clients. Our micro liquid liquid extractor combines CNC precision engineering with modular flexibility, offering unmatched corrosion resistance, leak-proof operation, and customizable configurations. Backed by 12 patented technologies, we empower industries from pharmaceuticals to environmental monitoring with reliable, scalable extraction systems.

Micro Liquid Liquid Extractor Description

Our micro liquid liquid extractor is a compact, desktop-ready system ideal for lab-scale solvent extraction, isotope separation, and precision chemical analysis. Designed for researchers and industrial labs, it ensures high recovery rates, adjustable mixing stages, and seamless integration with analytical instruments.

Specifications

| Specifications | Details |

|---|---|

| Model | Simple Desktop Platform Edition |

| Mixing Volume | 20ml, 25ml, 50ml, 80ml, 100ml, 125ml (Customizable) |

| Wall Thickness | 8mm, 10mm, 12mm |

| Materials | PMMA, PTFE, PEEK, Titanium (Corrosion-resistant options available) |

| Production Process | CNC Integral Forming |

| Matching Equipment | Optional Micro Injection Pump |

| Key Advantages | 99.5% Extraction Rate, Zero Leakage, Adjustable Speed (50–800 RPM) |

Why Choose Our Micro Liquid Liquid Extractor?

- Customization First: Tailor materials, sensor integrations (pH, temperature), and mixing volumes to your workflow.

- Durability Guaranteed: Titanium and PEEK options withstand aggressive solvents and high temperatures.

- Research-Backed Design: Developed by a team from top Chinese universities with 9+ extraction process patents.

- Global Compliance: Meets ISO 9001, CE, and FDA-compatible material standards.

Material & Processing Excellence

- PMMA: Optically clear for real-time phase observation.

- PTFE: Ideal for acidic/alkaline environments.

- PEEK: High-temperature stability (up to 250°C).

- Titanium: Ultra-lightweight with aerospace-grade corrosion resistance.

Smart Functions for Effortless Operation

- Anti-Bubbling Tech: Achieve clear phase separation with our vortex-free agitation.

- One-Step Tank Control: Fill or empty chambers in seconds via ergonomic valves.

- Modular Expansion: Add mixing stages or sensors without disassembling the core system.

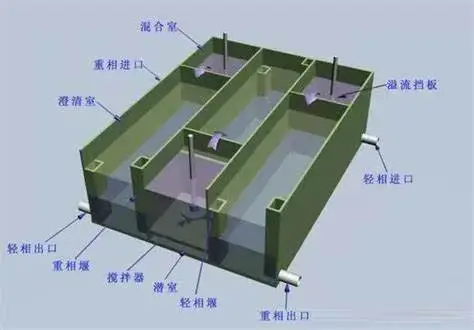

How It Works

- Mixing Phase: The agitator blends two immiscible liquids at adjustable speeds.

- Settling Phase: Laminar flow design ensures rapid, complete phase separation.

- Collection: Extract purified samples directly into vials or inline analyzers.

Compact Design, Powerful Performance

The 30cm x 20cm desktop unit features a transparent PMMA body for process visibility, stainless-steel fittings, and tool-free disassembly. Optional LED lighting enhances monitoring.

User Guide

- Setup

The setup phase is a meticulous process that lays the groundwork for seamless operation. First, carefully mount the unit on a stable surface, ensuring it is level to prevent any operational disruptions. Next, connect the tubing and pumps, making certain all connections are secure to avoid leaks. If the unit is equipped with sensors, calibration is crucial. Use reference standards to accurately set the sensor parameters. This ensures that the sensors provide precise data during operation, whether it's measuring temperature, pressure, or flow rate. A well - executed setup is essential for the unit to function optimally. - Operation

During operation, the digital interface simplifies the control process. Adjust the revolutions per minute (RPM) according to the requirements of the task at hand. For example, a higher RPM might be needed for more viscous substances to ensure proper mixing or agitation. Simultaneously, use the viewing window to monitor the process. Observe the flow of materials, any signs of abnormal behavior such as splashing or clogging, and the overall progress. The combination of digital control and visual monitoring allows for real - time adjustments to maintain efficient and effective operation. - Maintenance

Proper maintenance is key to the longevity of the unit. After each use, rinse it with ethanol. Ethanol effectively removes residues and contaminants that could accumulate over time and affect performance. Additionally, it is recommended to replace the seals annually. Seals prevent leaks and maintain the integrity of the internal components. Over time, seals can wear out due to friction and exposure to various substances. Annual replacement ensures that the unit continues to operate without leaks, safeguarding its functionality and the safety of the surrounding environment.

Industries We Serve

- Pharmaceuticals: API purification, drug metabolite studies.

- Environmental Labs: Heavy metal detection in water/soil.

- Nuclear Research: Isotope separation with titanium extractors.

- Food Safety: Pesticide residue analysis.

Packaging & Transportation

Secure foam-lined crates with global air/sea freight options.

Warranty

3-year limited warranty + lifetime technical support.

FAQs

- Can I integrate this with my existing HPLC system?

Yes! Our extractors support standard 1/4" tubing connectors. - What's the lead time for custom orders?

4–6 weeks, depending on material availability. - Do you provide material compatibility charts?

Absolutely. Download our chemical resistance guide [here]. - Is the unit compatible with automated liquid handlers?

Yes – we offer robotic arm adapters. - What certifications do your products have?

CE, ISO 9001, and 8 national patents.

Contact Us

Elevate your extraction processes with a system trusted by BASF, Tsinghua University, and SGS. Email wangzhijun@cuiyan-tec.com for a quote or technical consultation of micro liquid liquid extractor.

VIEW MOREAutomated Extraction System

VIEW MOREAutomated Extraction System VIEW MOREContinuous Extractor

VIEW MOREContinuous Extractor VIEW MOREMixer Settler Extractor

VIEW MOREMixer Settler Extractor VIEW MORESolvent Extraction Mixer Settler

VIEW MORESolvent Extraction Mixer Settler VIEW MOREPilot Extraction System

VIEW MOREPilot Extraction System VIEW MOREMicro Isotope Extraction System

VIEW MOREMicro Isotope Extraction System VIEW MORELiquid Liquid Extraction Mixer Settler

VIEW MORELiquid Liquid Extraction Mixer Settler VIEW MORELiquid Liquid Extraction Industrial Equipment

VIEW MORELiquid Liquid Extraction Industrial Equipment