Navigating the evolving landscape of chemical research in 2025 requires precision tools that guarantee reliable outcomes at the laboratory scale. The lab scale mixer settler stands out as an indispensable instrument for chemical separation and solvent extraction, adept at reproducing real industrial processes in a controlled environment. This device provides unparalleled control over phase mixing, mass transfer, and settling time, enabling researchers and plant managers across Pharmaceuticals, Food & Beverage, Cosmetics, and Chemical industries to optimize their separation processes and scale up efficiently with confidence.

Understanding the Lab Scale Mixer Settler: Core Configurations and Features

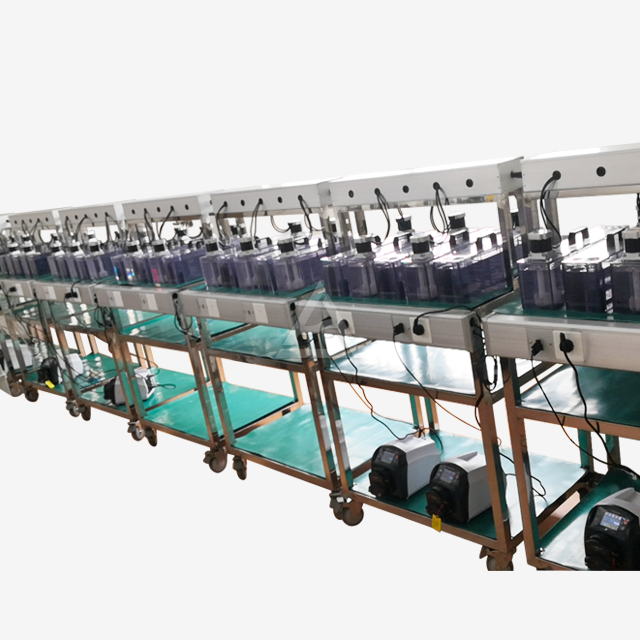

The architecture of a lab scale mixer settler varies to cater to diverse research demands. Shaanxi Cuiyan Technology Co., Ltd offers three principal configurations: the desktop base edition for bench-scale work, the mobile standard edition equipped for versatile setups, and the environmentally friendly high edition designed with sustainability in mind. Mixing volumes range from 200ml to 3L, adaptable to specific experimental requirements.

Construction materials such as PP, PPH, PVC, and corrosion-resistant SUS or Ti cater to aggressive solvents and delicate compounds alike, safeguarding purity and operational integrity. Manufacturing techniques including welding, bonding, and injection molding ensure product robustness and leak-free performance. Optional enhancements such as temperature control, pH adjustment, and water-bath jacket devices facilitate precise process optimization.

Unlocking High Extraction Efficiency and Customization

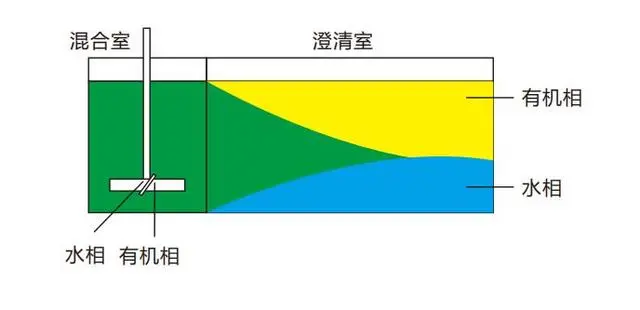

Extraction efficiency often hinges on meticulous mixer design and settling tank configuration. Each adjustable stage in the mixer settler allows fine-tuning of agitator speed and phase interface height, minimizing emulsion formation and maximizing mass transfer efficiency. Shaanxi Cuiyan's patented anti-bubbling technology ensures phase interfaces remain stable, essential for achieving extraction rates consistently exceeding 95%.

Customizability extends beyond mechanical control to integration with IoT-enabled sensors for real-time monitoring of pH, temperature, and mixing dynamics. This connects seamlessly to laboratory data acquisition systems, elevating laboratory testing to a new dimension of precision and reproducibility indispensable for GMP-compliant processes.

Applications in Pharmaceuticals, Food & Beverage, Cosmetics, and Industrial Fields

In pharmaceuticals and nutraceuticals, precise solvent extraction is critical for isolating active pharmaceutical ingredients (APIs) with ultra-high purity and compliance. Our lab scale mixer settler simulates industrial conditions allowing R&D teams to optimize extraction parameters for botanical extracts, ensuring scalability while maintaining GMP standards.

Food and beverage industries benefit from food-grade material choices and gentle mixing protocols that preserve volatile compounds in essential oils, flavors, and natural colors. High throughput capabilities paired with reliable phase separation secure process safety and product quality.

The cosmetics sector requires minimal shear and contaminant-free processes - attributes inherent to our mixer settlers equipped with transparent observation windows and mild agitation options, preserving bioactive compound integrity during extraction for skincare and fragrance formulations.

For chemical and industrial applications such as rare earth, nickel-cobalt, lithium battery recycling, and wastewater treatment, our systems exhibit exceptional chemical resistance and modular scalability. Robust materials like PTFE and SUS316L withstand harsh reagents, while adjustable stage numbers allow pilot testing before seamless scale-up.

Working Principle and Operational Guidelines

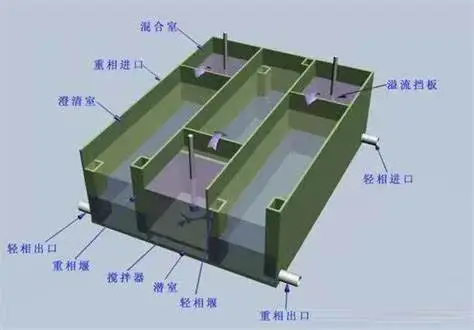

The fundamental principle of the mixer settler involves two main stages: vigorous mixing of immiscible solvents to achieve intimate contact between phases and subsequent settling for effective phase disengagement. Adjusting baffle positions and overflow weirs controls residence time and stabilizes phase interfaces, curbing emulsion formation.

Users should install the lab scale mixer settler on vibration-free surfaces and calibrate sensors through an intuitive touchscreen interface. Stepwise increasing agitator RPM - from low to operational levels - avoids premature emulsification. A one-step tank filling and emptying feature combined with leak-proof joints elevates laboratory efficiency.

Why Shaanxi Cuiyan's Lab Scale Mixer Settler Stands Out

Shaanxi Cuiyan Technology Co., Ltd harnesses over 12 years of extraction equipment excellence and hydrometallurgical line design expertise. Trusted by more than 300 global enterprises, the company innovates continuously with nine patented technologies that enhance operation automation, anti-bubbling, and rapid scalability.

Their modular, corrosion-resistant mixer settlers are constructed with precision machining and environmentally conscious materials. The company's holistic approach, from design to production and post-sales support, ensures researchers and production teams get a tailored solution aligned with stringent process engineering demands.

Enhancing Scale-up and Process Optimization with Mixer Settlers

Transitioning from laboratory findings to industrial application demands reliable scale-up strategies. The adjustable mixer settler stages and agitator customizable speeds contribute to mastering flow dynamics and emulsion breaking, essential for mass transfer enhancement.

Pilot testing with Shaanxi Cuiyan systems allows thorough process optimization while avoiding costly setbacks in commercial-scale operations. This builds confidence in separation process scaling with minimized risk, delivering consistent product quality across batch volumes.

Conclusion

Exploring extraction and separation methods through state-of-the-art lab scale mixer settlers accelerates innovation in chemical research. Shaanxi Cuiyan Technology Co., Ltd provides tailored, durable, and precision-engineered systems designed to meet diverse industrial needs with unmatched reliability and efficiency. Their commitment to quality and customization ensures your research and production scale seamlessly from lab to plant, safeguarding the integrity of sensitive compounds and optimizing industrial workflows.

Where to Buy Lab Scale Mixer Settler?

Discover premium-grade lab scale mixer settlers with Shaanxi Cuiyan Technology Co., Ltd, a renowned manufacturer since 2012 dedicated to chemical separation and extraction equipment. Whether you seek desktop base units or environmentally friendly editions, their expert team offers tailored solutions backed by patented innovations. Connect for detailed guidance and personalized consultation regarding lab scale mixer settler options best suited for your research or production needs. Contact us at wangzhijun@cuiyan-tec.com to inquire or request a demonstration.

References

King, C. J. (2023). "Liquid-Liquid Extraction: Principles and Practice." Journal of Chemical Technology.

Smith, R. and Jones, A. (2022). "Advances in Mixer Settler Design for Pilot Scale Applications." Separation Science Reviews.

Lee, H. et al. (2024). "Solvent Extraction Techniques in Pharmaceutical Development." International Journal of Pharmaceutics.

Wang, L. and Zhao, Q. (2023). "Optimization of Separation Processes in Battery Recycling." Chemical Engineering Progress.

Garcia, M. and Patel, S. (2022). "Materials Selection for Corrosion-Resistant Laboratory Equipment." Materials Science and Technology.

Thompson, D. (2023). "Process Scale-Up Strategies Using Modular Mixer Settlers." Industrial & Engineering Chemistry Research.