Understanding Mixer Settler Technology and Its Applications

The Fundamentals of Mixer Settler Operation

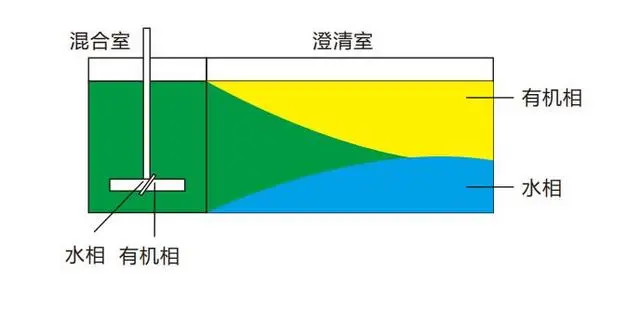

Mixer settlers are vital components in various extraction processes across industries. These versatile devices consist of two main sections: the mixing chamber and the settling zone. In the mixing chamber, two immiscible liquids are vigorously blended to facilitate mass transfer. The agitator's speed and design play a crucial role in achieving optimal contact between the phases. Following mixing, the combined liquids flow into the settling zone, where gravity separation occurs. The heavier phase settles to the bottom, while the lighter phase rises to the top. Adjustable weirs control the interface level, ensuring efficient phase separation.

Key Industries Benefiting from Mixer Settler Technology

Mixer settlers find applications in a wide range of industries due to their efficiency and versatility. In the mining sector, they're instrumental in extracting valuable metals like copper, nickel, and rare earth elements from ore leachates. The pharmaceutical industry relies on mixer settlers for purifying active ingredients and separating enantiomers. In nuclear fuel processing, these devices play a critical role in uranium and plutonium separation. Environmental applications include wastewater treatment, where mixer settlers help remove heavy metals and organic contaminants. The petrochemical industry utilizes them for solvent recovery and product purification.

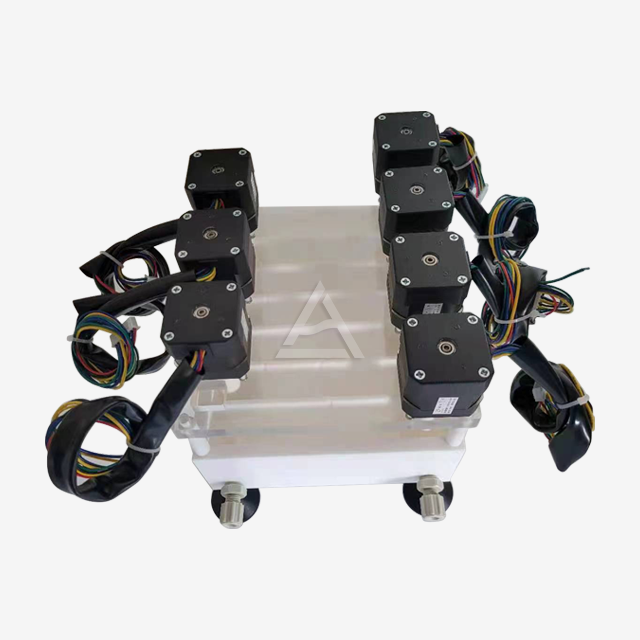

Advancements in Mixer Settler Design

Recent innovations have significantly enhanced mixer settler performance and efficiency. Modern designs incorporate features like anti-overflow tanks to prevent spills and improve safety. Some models now include integrated temperature control systems, allowing precise regulation of extraction conditions. Advanced materials such as PEEK and titanium offer superior corrosion resistance for challenging chemical environments. Computational fluid dynamics simulations have led to optimized baffle designs, reducing turbulence and improving phase separation. Additionally, the integration of inline sensors and PLC controls enables real-time monitoring and adjustment of critical parameters like pH and flow rates.

Essential Factors to Consider When Evaluating Mixer Settler Suppliers

Material Selection and Compatibility

The choice of materials for your mixer settler is paramount to its performance and longevity. Suppliers should offer a range of options to suit various chemical environments. For corrosive applications, look for materials like polypropylene (PP), polytetrafluoroethylene (PTFE), or high-grade stainless steel (SUS316L). These materials can withstand pH ranges from 1 to 14, ensuring durability in both acidic and alkaline conditions. For processes requiring visual inspection, transparent materials such as PMMA (acrylic) or PVC may be preferable. Consider the temperature range of your process as well – some polymers may not be suitable for high-temperature applications. A reputable supplier should be able to provide detailed compatibility charts and advise on the best material for your specific needs.

Customization Capabilities and Flexibility

The ability to tailor a mixer settler to your exact specifications can significantly impact its effectiveness in your process. Look for suppliers who offer a range of customization options. This may include adjustable mixing volumes (from 200ml to 3L or more), variable plate thicknesses (5mm to 10mm), and modular designs that allow for easy scaling of extraction stages. The option to customize agitator speed (typically 100-800 RPM) and phase interface height is crucial for optimizing mass transfer and separation efficiency. Additionally, consider suppliers who can integrate optional features like pH adjustment devices, water-bath jackets for temperature control, or specialized baffle designs for unique fluid dynamics. A supplier's willingness to work closely with your engineering team to develop bespoke solutions is a strong indicator of their expertise and commitment to customer satisfaction.

Quality Assurance and Compliance Standards

When dealing with sensitive extraction processes, the quality and reliability of your mixer settler are non-negotiable. Reputable suppliers should adhere to stringent quality control measures throughout their manufacturing process. Look for certifications such as ISO 9001 for quality management systems. For applications in regulated industries like pharmaceuticals or nuclear processing, compliance with standards like ASME BPE (Bioprocessing Equipment) or REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) may be necessary. Ask potential suppliers about their testing procedures – do they perform leak tests, material certifications, or performance validations? Additionally, inquire about their documentation practices. Comprehensive documentation, including material certificates, welding records, and performance test results, is essential for regulatory compliance and process validation.

Maximizing Value: Beyond the Initial Purchase

After-Sales Support and Maintenance Services

The relationship with your mixer settler supplier shouldn't end at the point of purchase. Robust after-sales support can significantly impact the long-term value of your investment. Look for suppliers who offer comprehensive maintenance packages, including regular inspections, seal replacements, and performance optimizations. Some suppliers provide remote monitoring services, allowing for predictive maintenance and minimizing downtime. Training programs for your operators can ensure optimal usage and extend the equipment's lifespan. Consider the availability of spare parts and the supplier's response time for urgent repairs. A supplier with a global service network can be particularly advantageous for multinational operations, ensuring consistent support across different locations.

Energy Efficiency and Sustainability Considerations

In today's environmentally conscious industrial landscape, the energy efficiency of your mixer settler can have significant implications for both operating costs and sustainability goals. Progressive suppliers are incorporating energy-saving features into their designs. Look for models with high-efficiency motors and optimized impeller designs that reduce power consumption without compromising mixing effectiveness. Some advanced systems include variable frequency drives (VFDs) that adjust motor speed based on process requirements, potentially reducing energy usage by 15-20% compared to fixed-speed systems. Consider the overall environmental impact of the mixer settler, including the recyclability of materials used in its construction and the supplier's own sustainability practices. Suppliers who offer life cycle assessments of their products can provide valuable insights into the long-term environmental and economic impacts of your choice.

Integration with Existing Systems and Future Scalability

The ability of a mixer settler to seamlessly integrate with your existing process equipment and control systems is crucial for operational efficiency. Look for suppliers who offer flexible interface options, such as standardized I/O protocols for easy connection to your plant's SCADA or DCS systems. Some advanced mixer settlers come with built-in PLC controls that can be easily programmed to match your specific process logic. Consider the physical footprint and connection points of the mixer settler – a compact, modular design can simplify installation and future expansions. Forward-thinking suppliers may offer options for IoT connectivity, enabling remote monitoring and data analytics. This can be particularly valuable for process optimization and predictive maintenance. When evaluating scalability, consider not just the ability to add more stages, but also the supplier's capacity to provide larger units or different configurations as your production needs evolve.

Conclusion

Choosing the right mixer settler supplier is a critical decision that can significantly impact your extraction processes' efficiency, reliability, and overall success. By carefully considering factors such as material compatibility, customization options, quality assurance, after-sales support, energy efficiency, and system integration, you can make an informed choice that aligns with your specific needs and long-term goals. Remember, the best supplier is not just a vendor but a partner in your operational success, offering expertise, innovation, and ongoing support to optimize your extraction processes.

Contact Us

Ready to elevate your extraction processes with a state-of-the-art mixer settler? Cuiyan Technology offers cutting-edge solutions tailored to your unique requirements. Our expert team is committed to providing superior quality, innovative designs, and unparalleled support. Contact us today at wangzhijun@cuiyan-tec.com to discuss how we can optimize your extraction operations and drive your success.